Method for paving large-diameter pipeline in soft soil in jacking and pulling combined manner

A large-diameter pipe technology, which is applied in the field of laying large-diameter pipes in soft soil by using top-pull combination, can solve the problems of insufficient safety and reliability, high cost, and high cost of construction machinery, and achieve simple and feasible structure and principle, and great development prospects , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

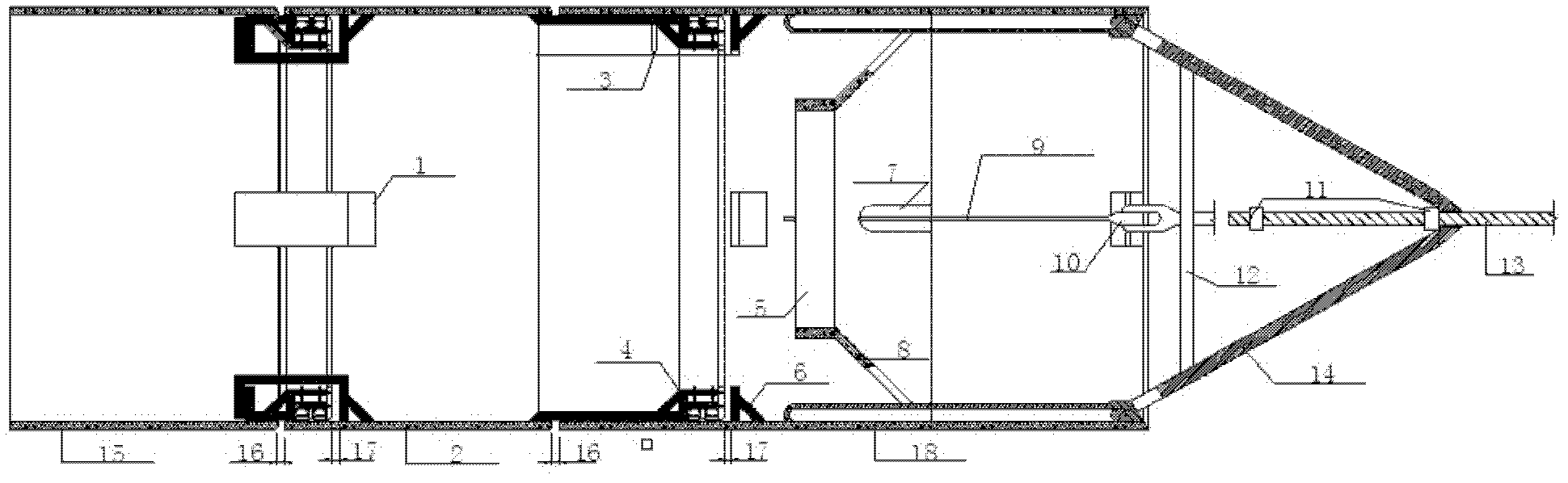

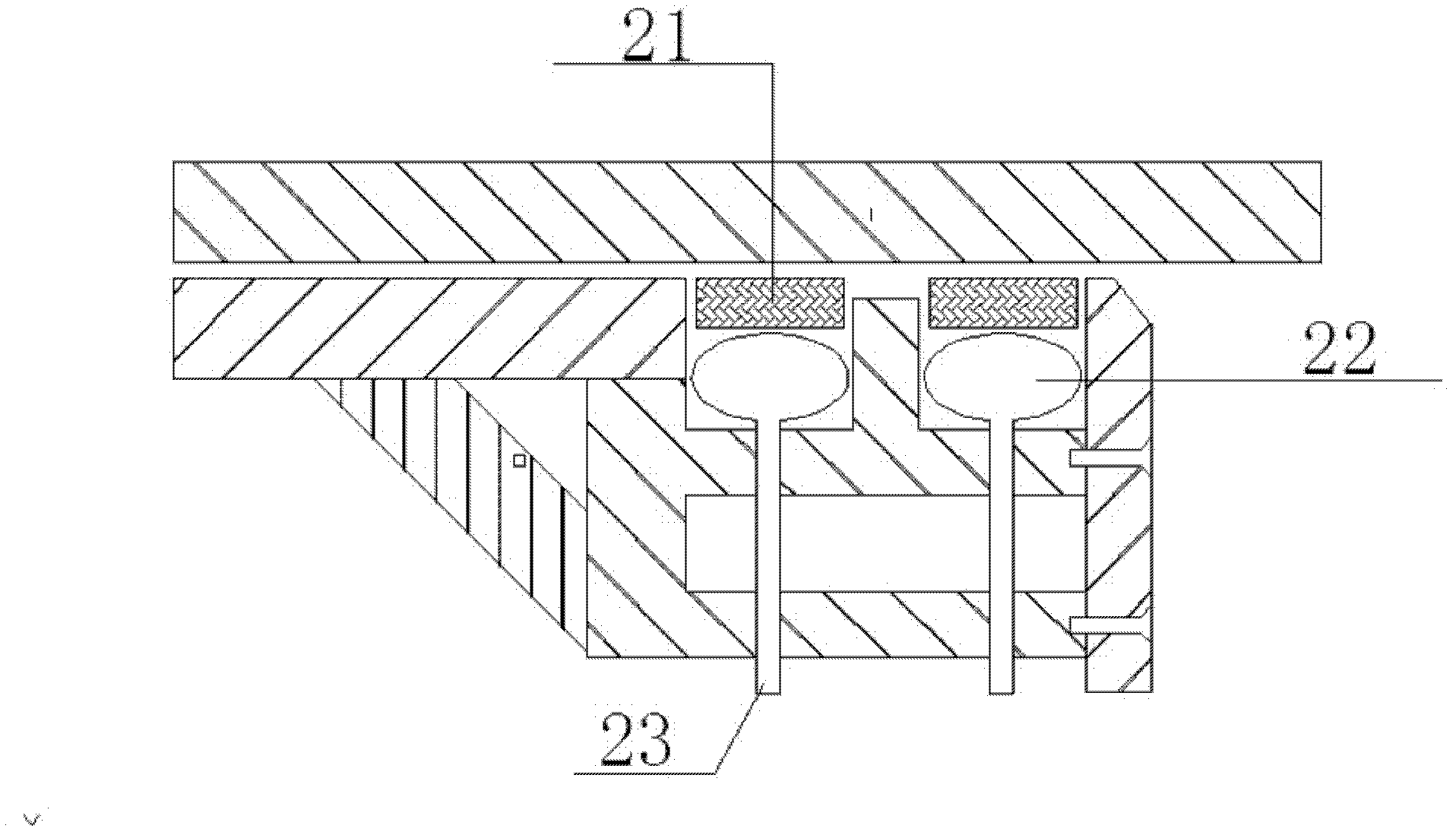

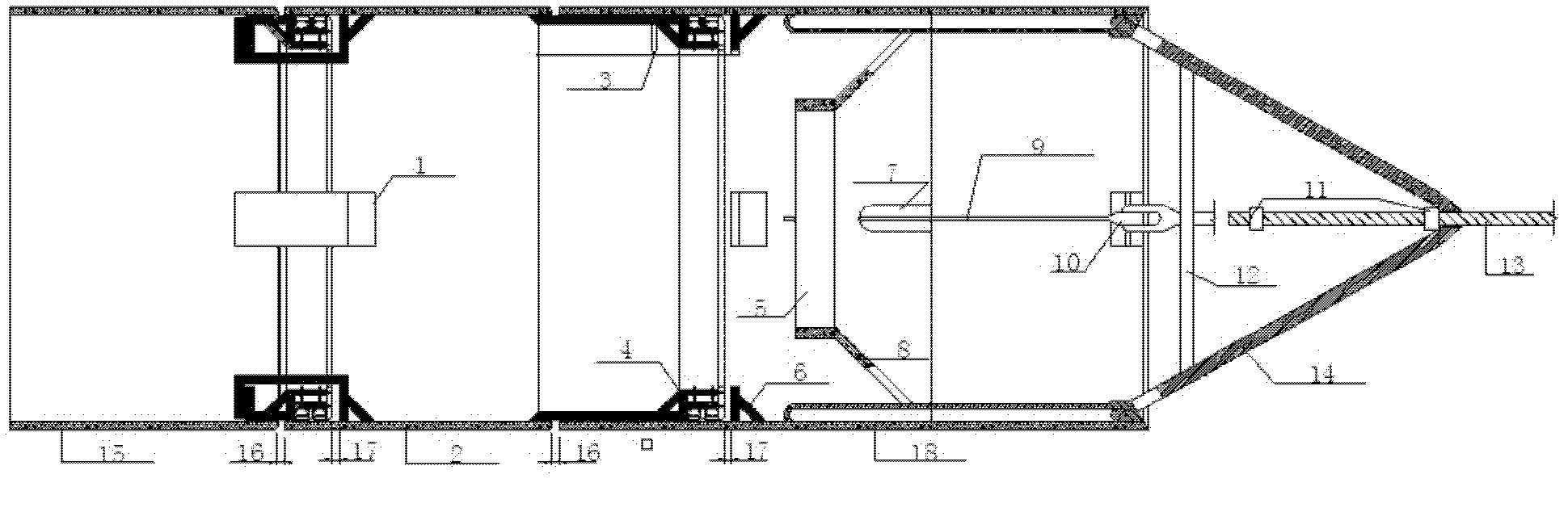

[0052] Below in conjunction with accompanying drawing, the present invention will be further described, and the structure and principle of this device are very clear to those skilled in the art.

[0053]The main feature of the present invention is that the pullback force of the horizontal directional drilling rig provides traction force for the open or partially open pipe jacking tool pipe, guiding the tool pipe to advance along the design axis; the jack in the pipe jacking pit is formed by the pipe along the tool pipe The axis advances to provide jacking force to make the pipeline extend forward. The specific construction process is as follows:

[0054] 1. Make tool tube

[0055] The key point of this method is to design a brand-new tool tube suitable for laying large-diameter pipelines in soft soil using top-pull combination. Taking the construction of a pipeline with an outer diameter of 1.5m as an example, draw a schematic diagram of the tool tube.

[0056] The function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com