Test method for determining beer foam stability

A foam stability and test method technology, applied in analytical materials, instruments, etc., can solve the problems of reduced reliability of measurement methods, great influence of temperature fluctuations, and difficulty in accurately clarifying the relationship between foam active components, so as to improve the degree of automation and data. The effect of improved processing power and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1.1 Test purpose: evaluation of beer foam dynamic defoaming process

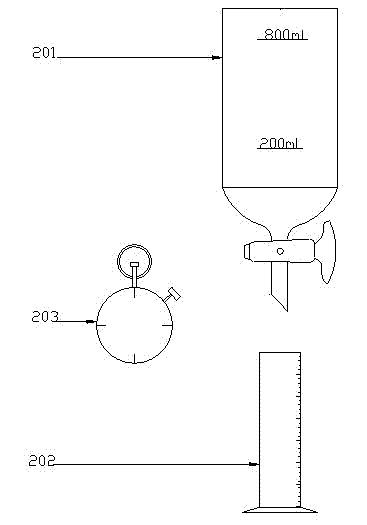

[0062] 1.2 Test principle: The defoaming process is a process in which the upper bubble level keeps decreasing and the lower bubble level keeps rising. Record the time it takes for the bubble level to rise by one volume scale, and then continue to calculate the foam equivalent volume corresponding to each moment point, and observe the dynamic change of the foam volume over time. The fluctuation of foam volume and defoaming rate during the defoaming process can be obtained by the matching defoaming curve analysis software.

[0063] 1.3 The test steps are as follows:

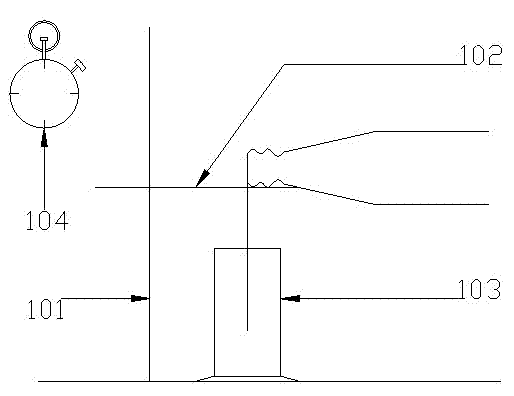

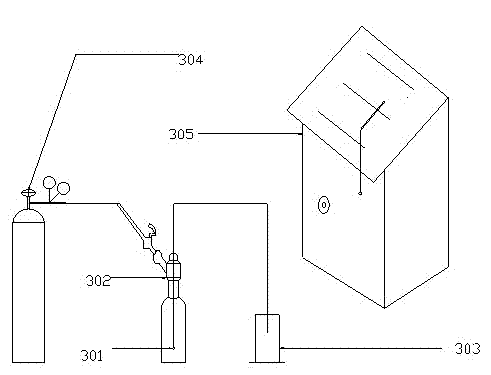

[0064] 1.3.1 Insufflation of CO 2 Air bubbling:

[0065] (1) Adjust the low temperature and constant temperature water bath to stabilize the temperature at the set value of 15~65°C;

[0066] (2) Slowly pour the degassed beer into the foam thermostat, and pre-constant for 15-30 minutes;

[0067] (3) Adjust the sandhead gear to the pre...

Embodiment 2

[0079] 2.1 Purpose of the test: Evaluation of foam stability of different brands of beer

[0080] 2.2 Experimental principle: The defoaming curve of beer foam is a typical three-segment curve, and the slope of the fitting line of the second segment curve can reflect the foam retention of foaming substances in beer, and it can be compared with the foam retention time measured by the stopwatch method. There is a significant correlation, so the slope of the second section of the defoaming curve can be used to characterize the size of the foam stability.

[0081] 2.3 The test steps are as follows:

[0082] 2.3.1 Insufflation of CO 2 Air bubbling:

[0083] (1) Adjust the low temperature and constant temperature water bath to stabilize the temperature at the set value of 15~65°C;

[0084] (2) Slowly pour the degassed beer into the foam thermostat, and pre-constant for 15-30 minutes;

[0085] (3) Adjust the sandhead gear to the preset value (1~7 gears are available);

[0086] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com