Method for detecting pressing mark of photovoltaic aluminum section on line

A detection method and aluminum profile technology, applied in the direction of material analysis, measuring device, and material analysis through optical means, can solve the problems of production efficiency limitation, dusty workshop site, harsh working environment, etc., and achieve shock resistance and earthquake resistance Good, simple installation, reliable detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

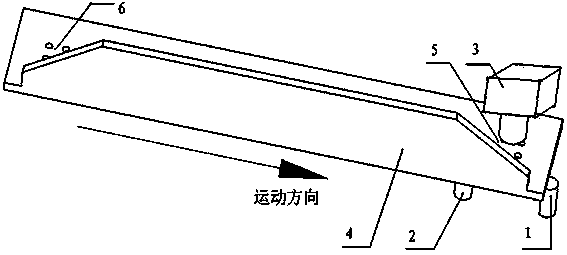

[0030] First, build as figure 1 The indentation online detection system shown. Install the start photoelectric switch 1, the end photoelectric switch 2 and the camera 3 on the detection device of the aluminum profile conveyor belt. The start photoelectric switch 1 and the end photoelectric switch 2 are connected to the camera 3 respectively. And the start photoelectric switch 1, the end photoelectric switch 2 and the camera 3 are connected with the electric control system with the industrial computer as the core for processing and judging the detection signal (the industrial computer is in the figure 1 not shown). The start photoelectric switch 1 can detect the arrival of the workpiece, and at the same time give the camera 3 a shooting command; the end photoelectric switch 2 can detect the end of the workpiece, and at the same time give t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com