Efficient, continuous and intelligent system for monitoring thickness of slime water clear water layer on line

A technology of slime water and clear water layer, which is applied in the direction of measuring device, engine lubrication, liquid/fluid solid measurement, etc. It can solve problems such as pollution, manual inspection workload, unstable production process system, etc., and achieve distance measurement for pollution prevention sensors, reduce labor intensity of workers, and ensure safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

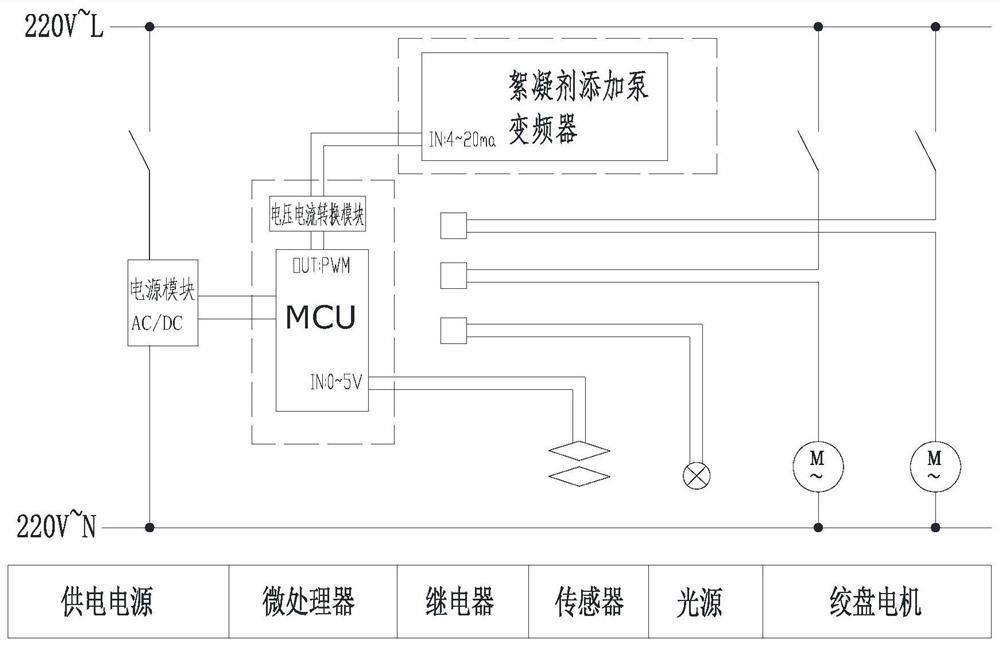

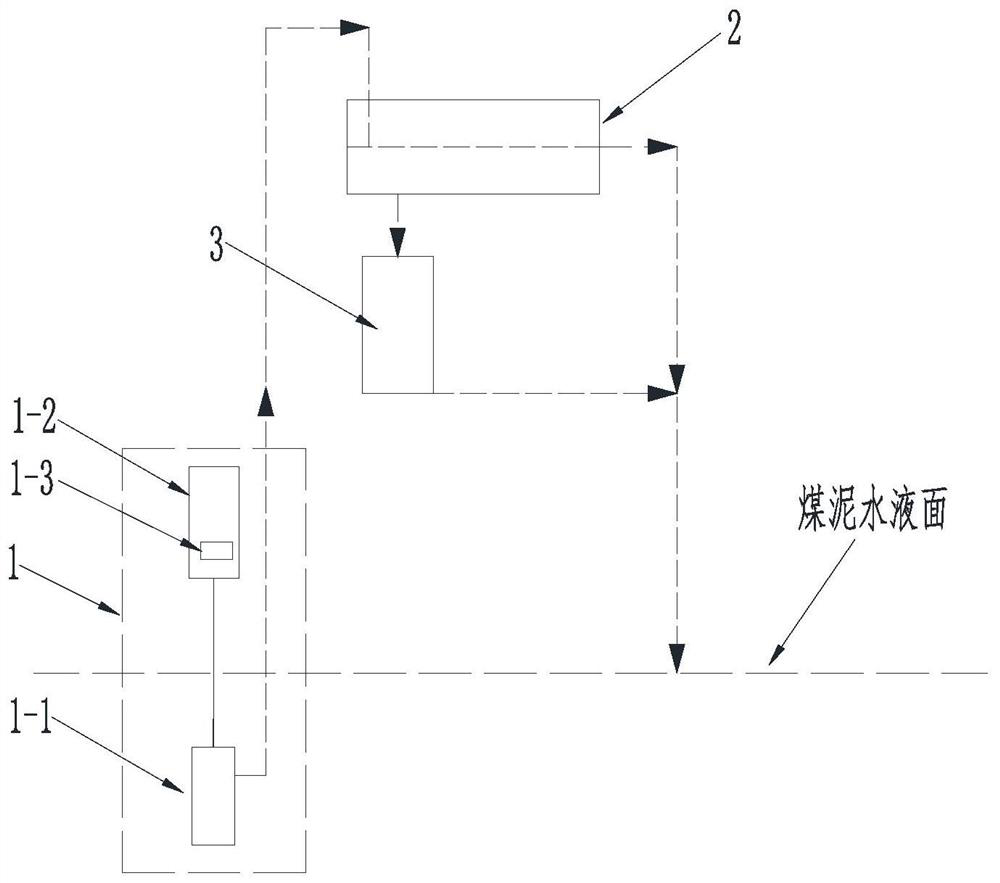

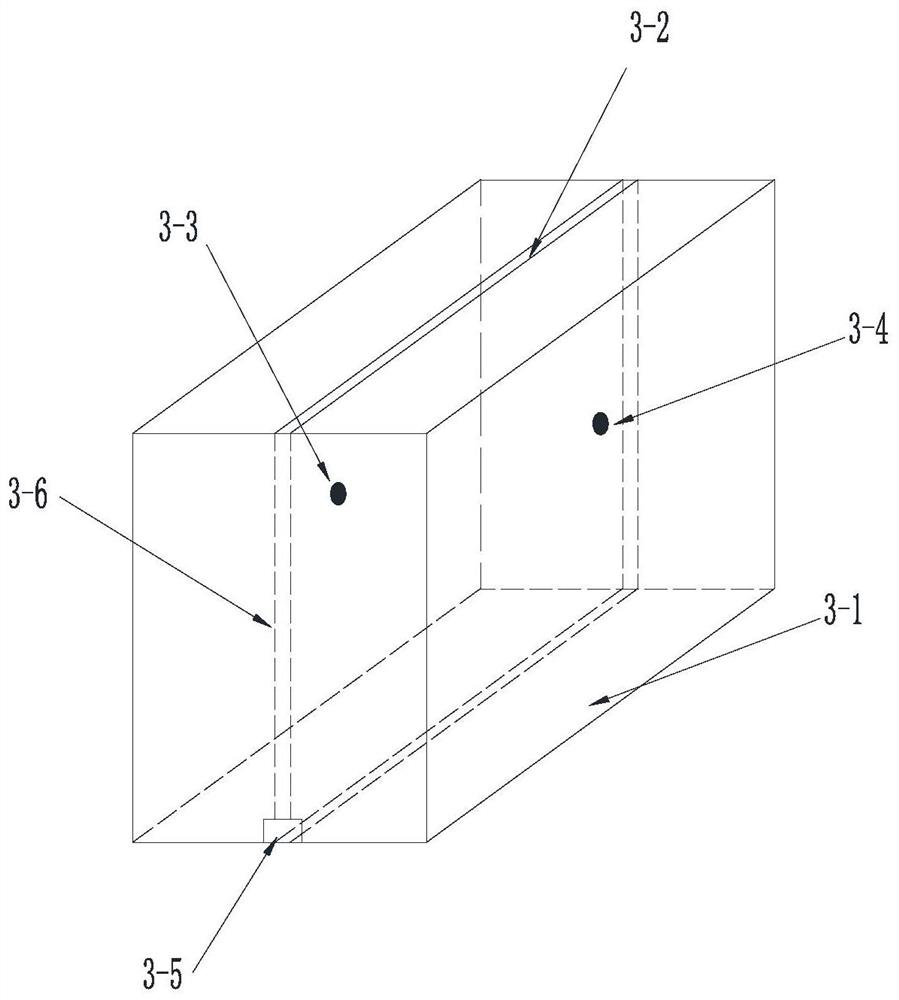

[0027] Such as figure 1 , figure 2 , Figure 6 As shown, an efficient and continuous intelligent online monitoring system for the thickness of the slime water clear water layer, which includes an adjustment distance measuring unit 1, a coal slime water turbulence box 2, a coal slime water concentration monitoring unit 3 and a control unit 4; the adjustment distance measurement unit The outlet end of the water intake pipe of 1 is connected with the first coal slime water inlet 2-2 of the coal slime water turbulent flow box 2; The muddy water inlet 3-2 is connected; And the size and shape of the first water outlet 2-5 and the second coal slime water inlet 3-2 are exactly the same; The signal output terminal and the control unit of the distance measuring sensor 1-3 of the adjustment distance measuring unit 1 The signal input end of 4 is connected; the signal output end of the photosensitive sensor 3-4 of slime water concentration monitoring unit 3 is connected with the signal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com