Method for detecting specification and size of plastic plate

A technology of plastic plate and size, applied in the direction of measuring device, material capacitance, instrument, etc., can solve the problems of low quantitative accuracy, low volume defect detection rate, no direct witness record of test results, etc., to achieve customer service damage and savings The effect of labor cost and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

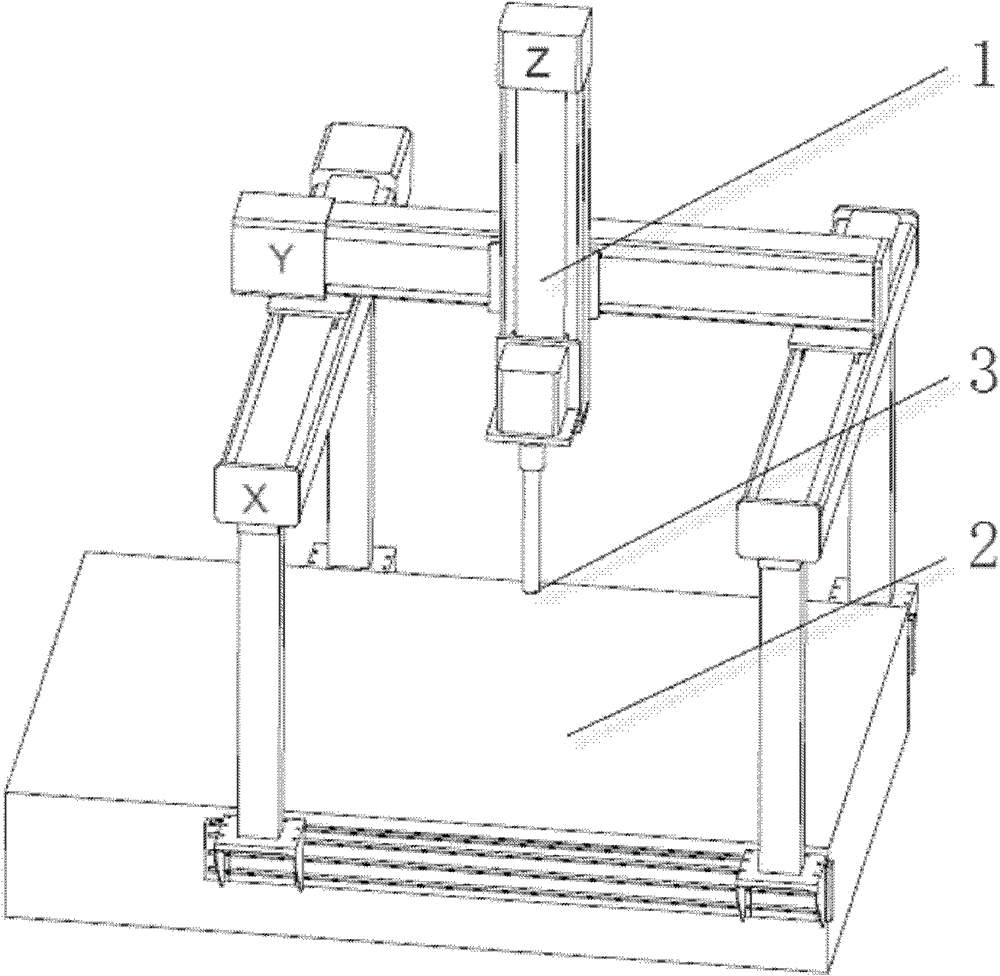

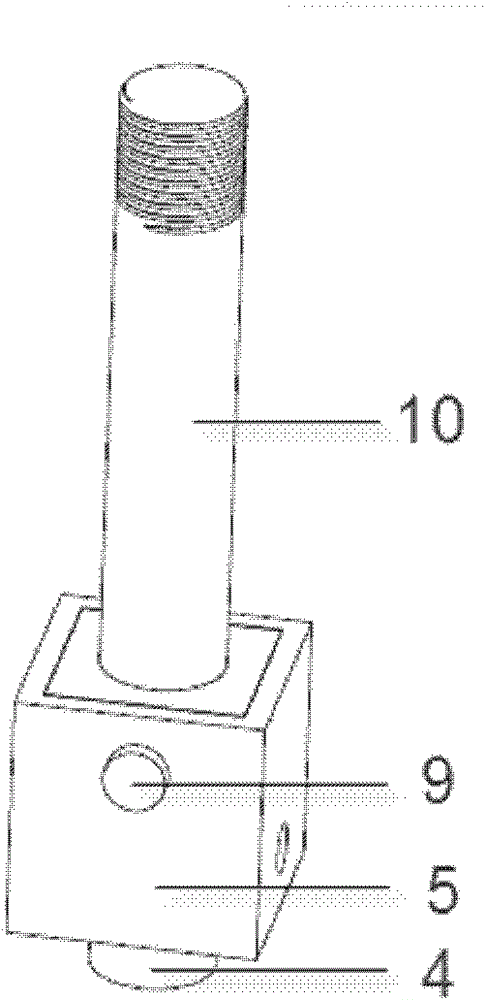

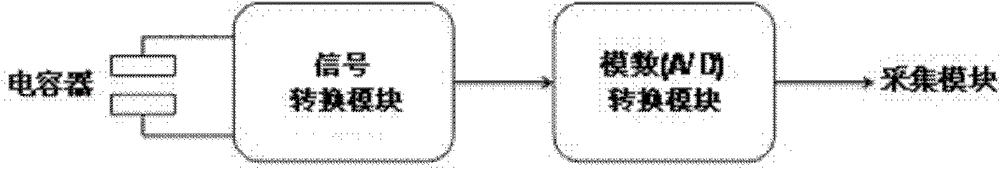

[0033] see figure 1 and figure 2 , the method for detecting the size of a plastic plate according to the present invention is based on a motion unit 1 that can be positioned at any point in the set space, a capacitor for scanning detection and a capacitance measurement unit for receiving and converting signals, wherein the motion unit 1 The positioning point 3 is connected with the mobile pole plate 4 as a pole of the capacitor through the interface 10, the mobile pole plate 4 is made of metal material, preferably stainless steel, and the direction opposite to the mobile pole plate 4 is provided with a base 2 for placing plastic products as a capacitor The other pole, the base 2 is also made of metal material, the lower surface of the moving pole plate 4 is parallel to the upper surface of the base 2, and a detection vacancy is provided between the two pole plates. The mobile pole plate 4 and the base 2 are also respectively provided with wires connected to the capacitance m...

Embodiment 2

[0044] Based on the system structure and theoretical basis described in Embodiment 1, the following introduces the method for checking the appearance size of flat plastic products using the scanning detection system of the present invention:

[0045] (1) see Figure 4 , placing the regular plastic plate 6 in the detection space on the supporting surface of the base 2;

[0046] (2) Adjust the height of the moving unit 1 in the vertical direction so that the lower surface of the mobile pole plate 4 is close to the upper surface of the plastic plate 6, and the height is locked so that the mobile electrode 4 can only move on a certain horizontal plane. In this implementation In the example, the control system of the motion unit 1 instructs the stepper motor of the Z axis to adjust the stroke of the Z axis so that the distance between the lower surface of the moving pole plate 4 and the upper surface of the plastic plate 6 is between 1-10mm, and then further fine-tuned to 1-5mm A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com