A monitoring method of belt motion state based on video processing

A motion state and video processing technology, applied in the field of motion detection, can solve problems such as being easily affected by coal dust, mud, oil sludge, etc., reducing the accuracy of motion state detection results, and missing hardware installation costs, and achieving good completion. The effect of working tasks, reducing production costs, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

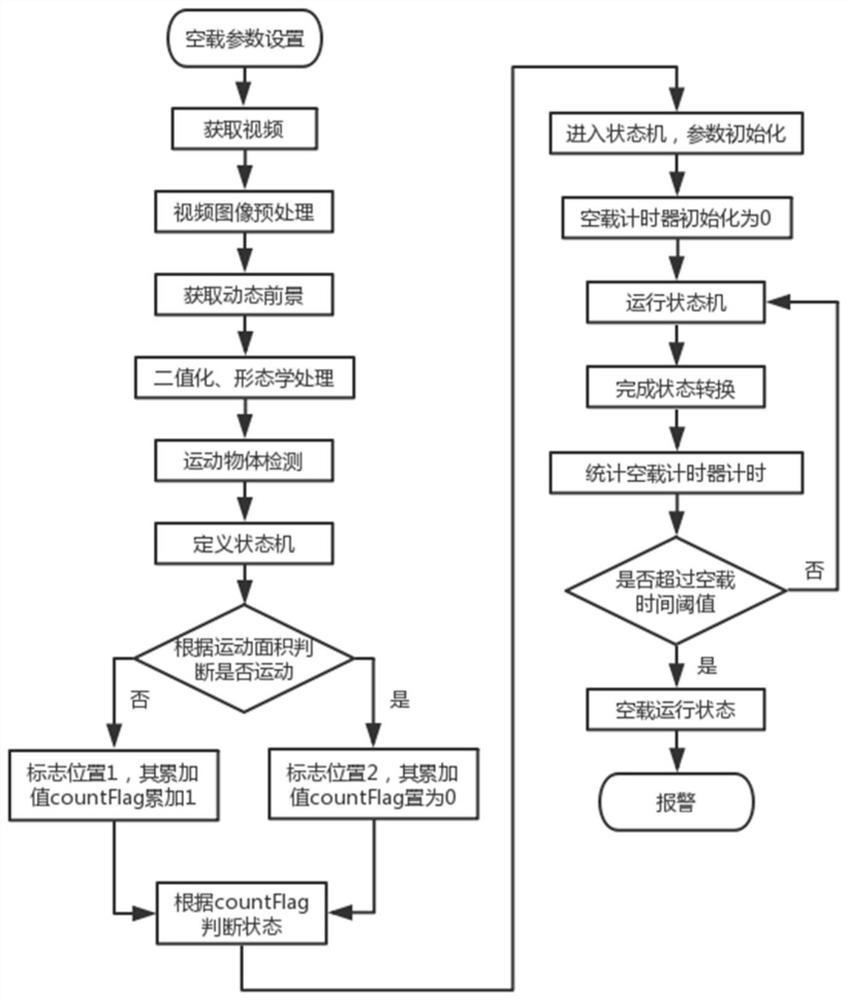

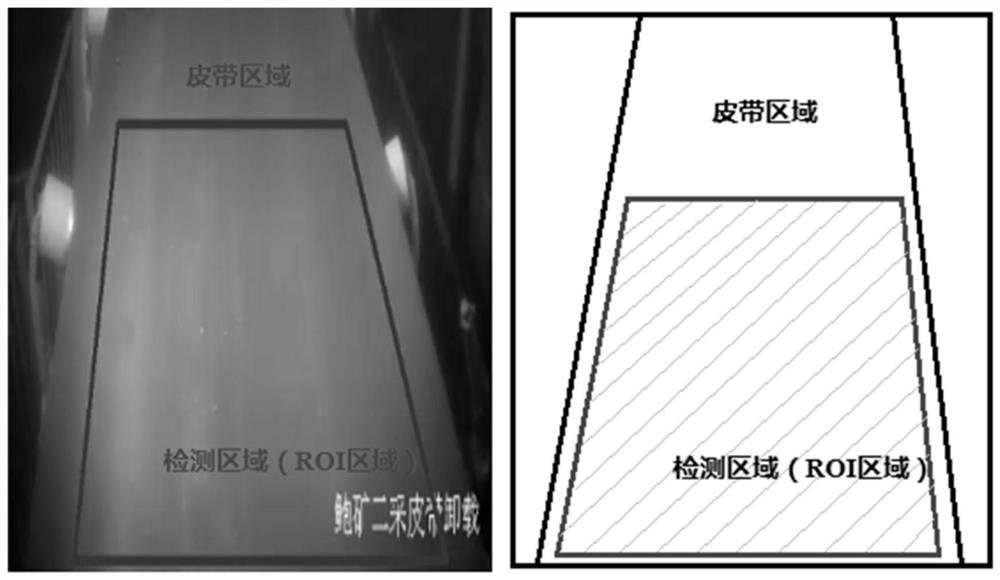

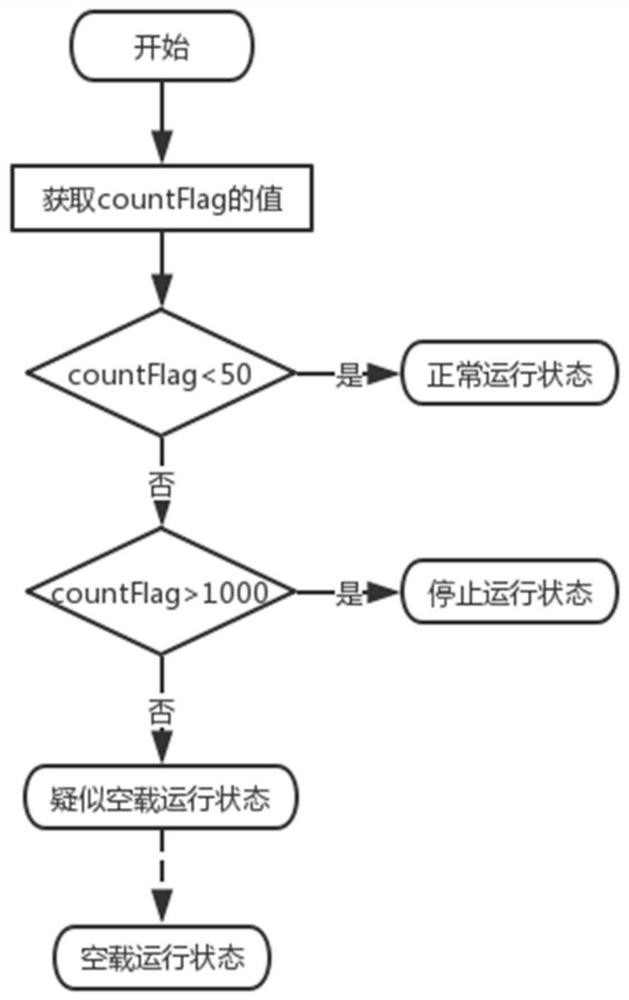

[0061] The present invention provides a method of monitoring the state of movement of the belt-based video processing. The present invention is carried out by real-time monitoring of the video analysis processing of the belt, the belt carries the motion state is determined during alarm and abnormal state, and may be determined to distinguish between normal and idling operation state and the operation state of the belt. When the pre-processing video frames, using Background Subtractor (background subtraction algorithm) KNN (K-Nearest, K nearest neighbor) background segmentation settings shadow detection, obtain dynamic foreground to the foreground of a video frame in accordance with the detection area of the moving object; defines a FSM (FiniteState machine, finite state machines), based on the area video motion area establishment flag is determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com