Compound pressure-bearing equipment internal flaw detection system capable of combining flux leakage coarse detection with ultrasonic accurate measurement

A pressure-bearing equipment and composite technology, applied in the direction of material magnetic variables, etc., can solve the problem of weak leakage magnetic field, and achieve the effects of high accuracy, good directivity, strong innovation and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

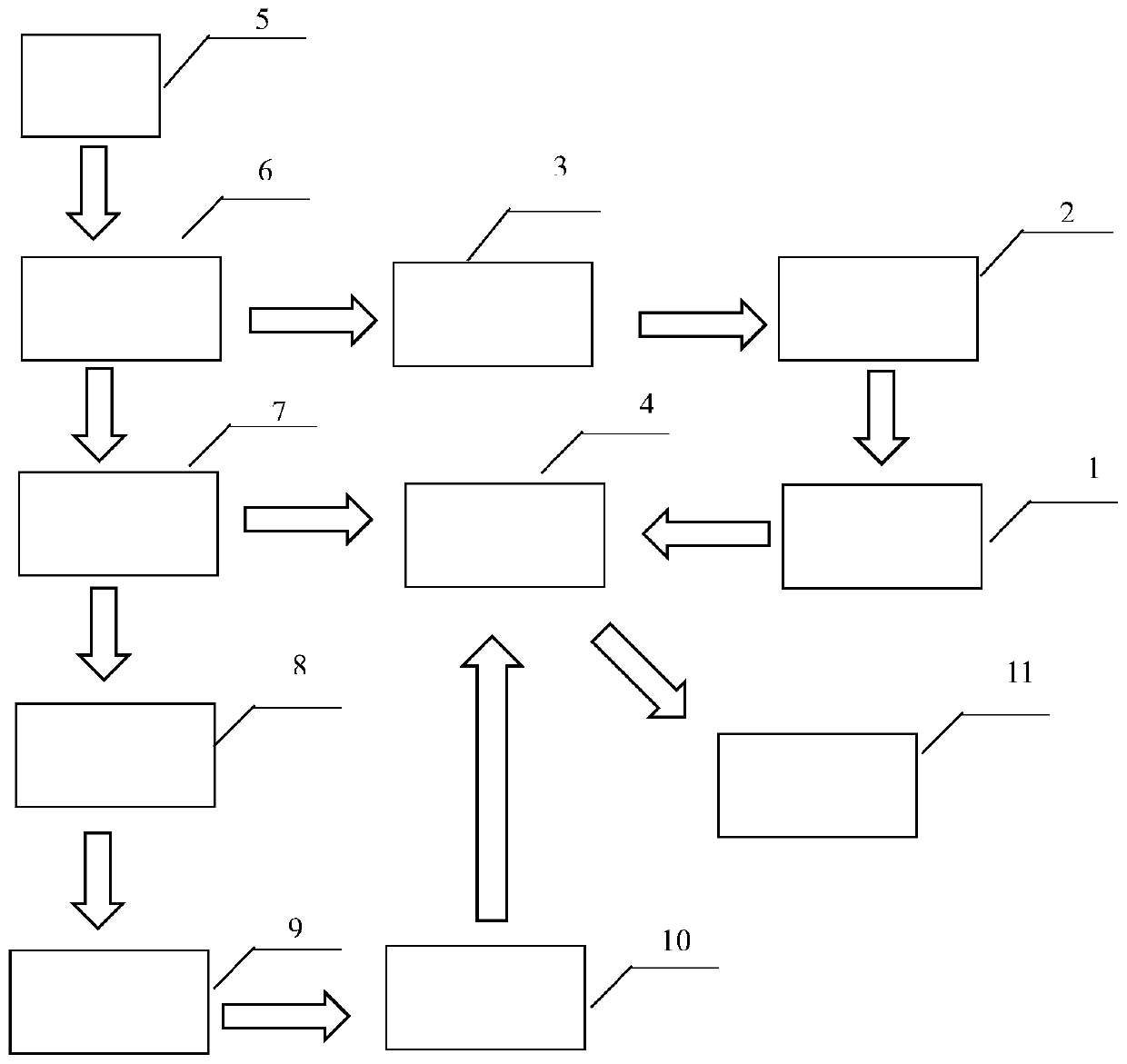

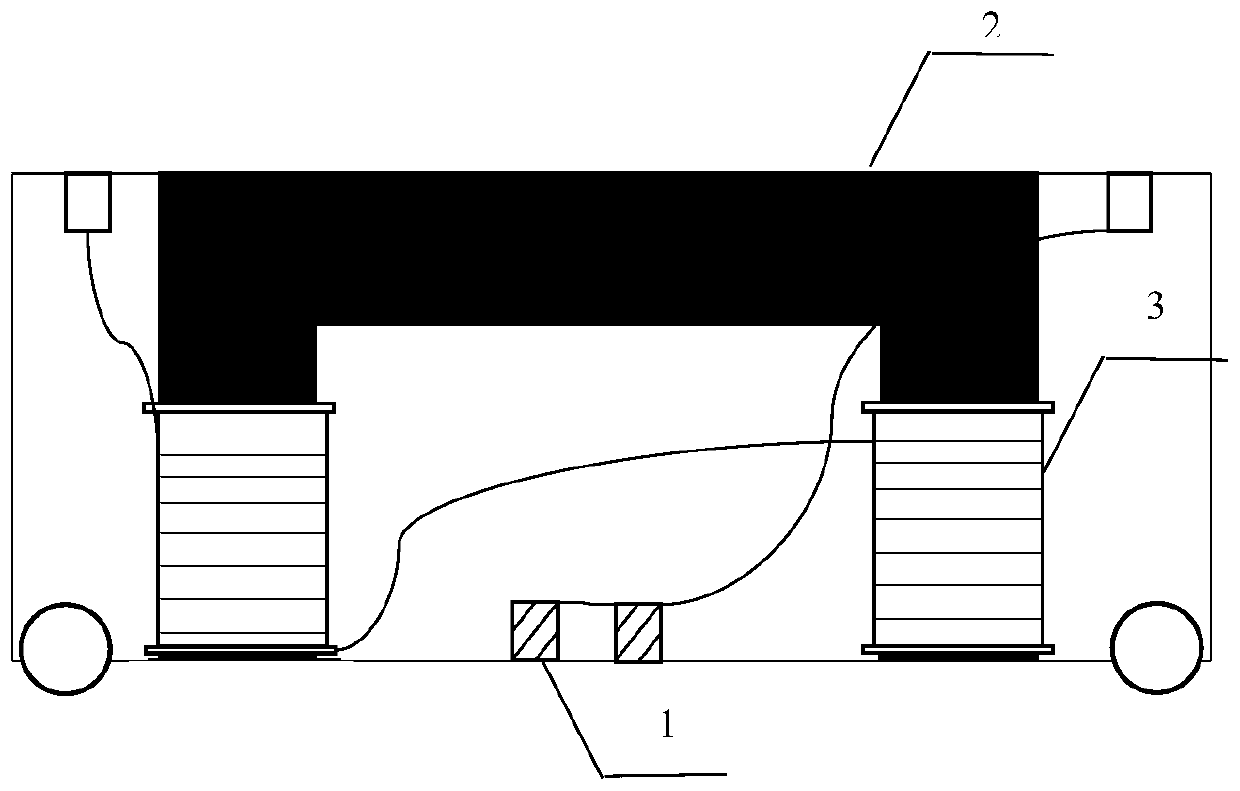

[0055] An internal flaw detection system for composite pressure-bearing equipment with coarse magnetic flux leakage detection combined with fine ultrasonic measurement, which consists of a Hall element array (1), a U-shaped magnetic core (2), an excitation coil (3), a signal processor (4), a power supply Module (5), single-chip microcomputer (6), power amplifier (7), excitation terminal impedance matching (8), transmitting probe (9), receiving probe (10), host computer composition (11); Hall element array (1) The 2*4 differential processing method is adopted, two rows of Hall elements are arranged back to back, the power supply module (5) supplies power to the entire system, the single-chip microcomputer (6) outputs low-frequency alternating signals to the excitation coil (3), and magnetizes the U-shaped magnetic core (2) Make it form a magnetic circuit with the component to be tested, form a local magnetic vacuum leakage environment, let the magnetic flux in the magnetic condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com