Digital flat panel ray detection ray source end robot based on Mecanum wheels

A technology of radiographic inspection and digital flat panel, applied in the direction of using radiation for material analysis, elastic suspension, suspension, etc., can solve the problems of blank, insufficient flexibility in welding seam inspection, inability to meet demand, etc., and reduce the manufacturing period and cost. , Realize the effect of testing automation and shortening testing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

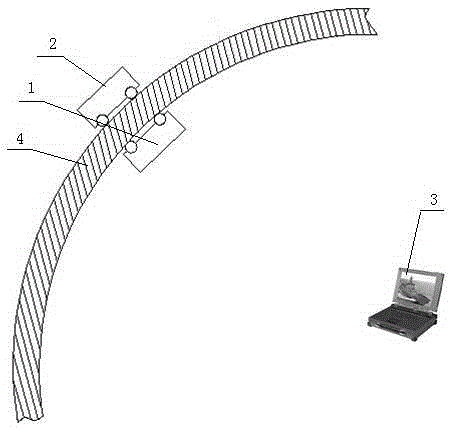

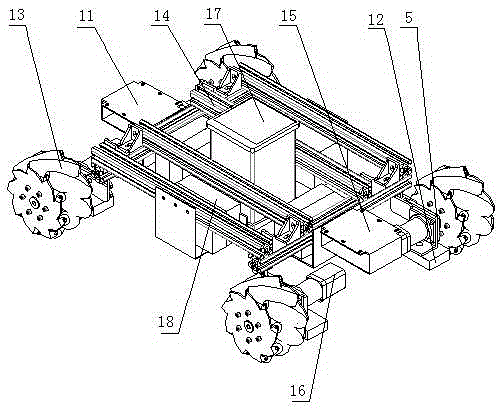

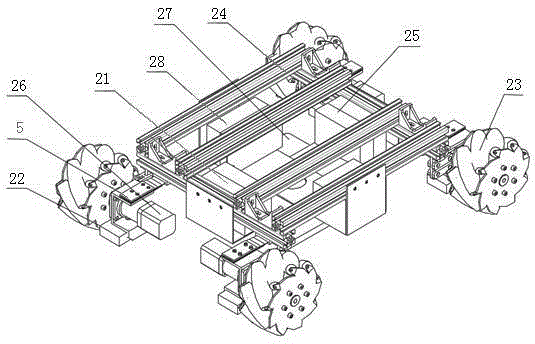

[0043] A digital flat-panel ray inspection system based on Mecanum wheels, such as figure 1, including host computer 3, ray source robot 1, and digital flat panel detector robot 2. Both ray source robot 1 and digital flat panel detector robot 2 adopt an all-round Mecanum wheel structure, and ray source robot 1 is equipped with motion control Box one 18, the motion control box one 18 is connected with the upper computer 3 and the digital flat panel detector robot 2 through the wireless communication module one, the motion control box one 18 is connected with the servo motor one 16 through the CAN communication module one, and the digital flat panel detector terminal robot 2 is provided with motion control box 2 28, motion control box 2 28 is connected with upper computer 3, ray source end robot 1 through wireless communication module 2, and motion control box 2 28 is connected with servo motor 2 26 through CAN communication module 2.

[0044] The ray source robot 1 includes a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com