Glazing machine of pin insulator

A pin-type insulator and insulator technology, applied in insulators, electrical components, circuits, etc., can solve the problems affecting the quality and price of pin-type insulators, low production efficiency, easy to form glaze beads, etc., and achieve comprehensive and uniform glazing and production efficiency. Improve, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

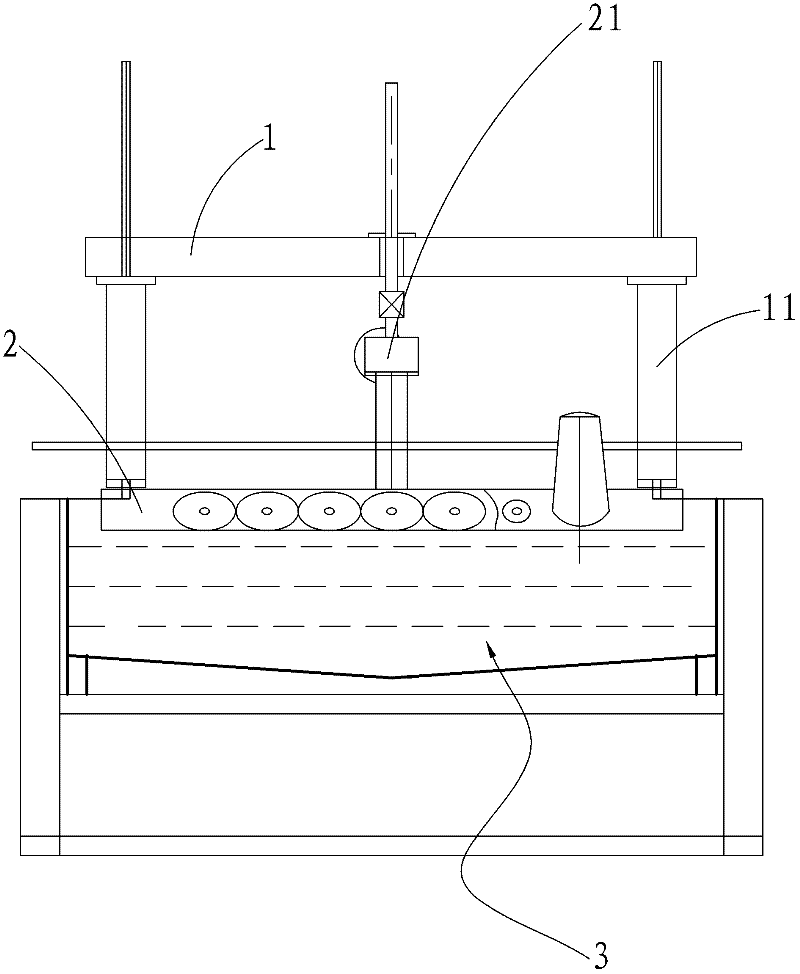

[0020] Please also refer to figure 1 , as shown in the figure, the embodiment of the needle insulator glazing machine of the present invention includes glaze water, a slot lifting and glazing device and a motor 21 .

[0021] The lifting and passing glaze device is arranged on the glaze water tank 3, and the lifting and passing glaze device includes a support frame 1 fixed on the glaze water tank 3, a cylinder arranged on the support frame 1 and a workpiece support 2 for placing pin insulators, and the cylinder 11 is vertical. Placed vertically, the lower end of the cylinder 11 is fixed at the end of the glaze water tank 3, and the top is fixed with the support frame 1. The workpiece support 2 is adapted to the shape of the glaze water tank 3, that is, the workpiece support 2 is Design the corresponding shape so that the workpiece support 2 can be lifted into the glaze water tank 3. For example, the glaze water tank 3 is a circular structure, and the workpiece support 2 is a co...

Embodiment 2

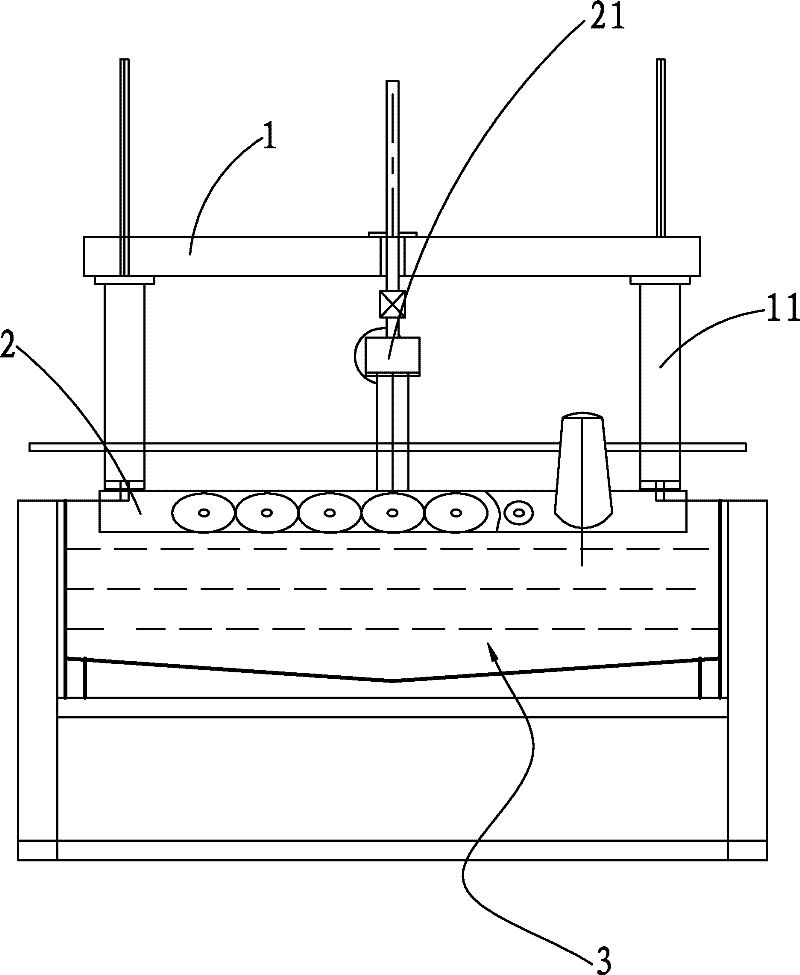

[0028] This embodiment is improved on the basis of Embodiment 1. There is no need to insert another plug-in rod on the rotating shaft, and the structure of the plug-in rod is directly designed on the rotating shaft, that is, the pin insulator is ready to be glazed. At this time, the workpiece support 2 is located on the glaze water tank 3, and the pin insulator is directly plugged on the rotating shaft, the starting motor 21 drives the rotating shaft and then drives the pin insulator to rotate, and the cylinder 11 is started, and the telescopic rod of the cylinder 11 stretches out to move the workpiece The support 2 is pressed into the glaze water of the glaze water tank 3, so that the entire pin insulator is immersed in the glaze water. After the glaze is completed, the telescopic rod of the cylinder 11 retracts, and the workpiece support 2 is taken out of the glaze water tank 3.

[0029] In this embodiment, one end of the optional shaft connected to the pin insulator is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com