Colum type electric porcelain insulator producing and spraying equipment

A technology of spraying equipment and insulators, which is applied in coatings, spray booths, spraying devices, etc., can solve the problems of uneven glazing and poor spraying quality, and achieve the effect of uniform glazing and good spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

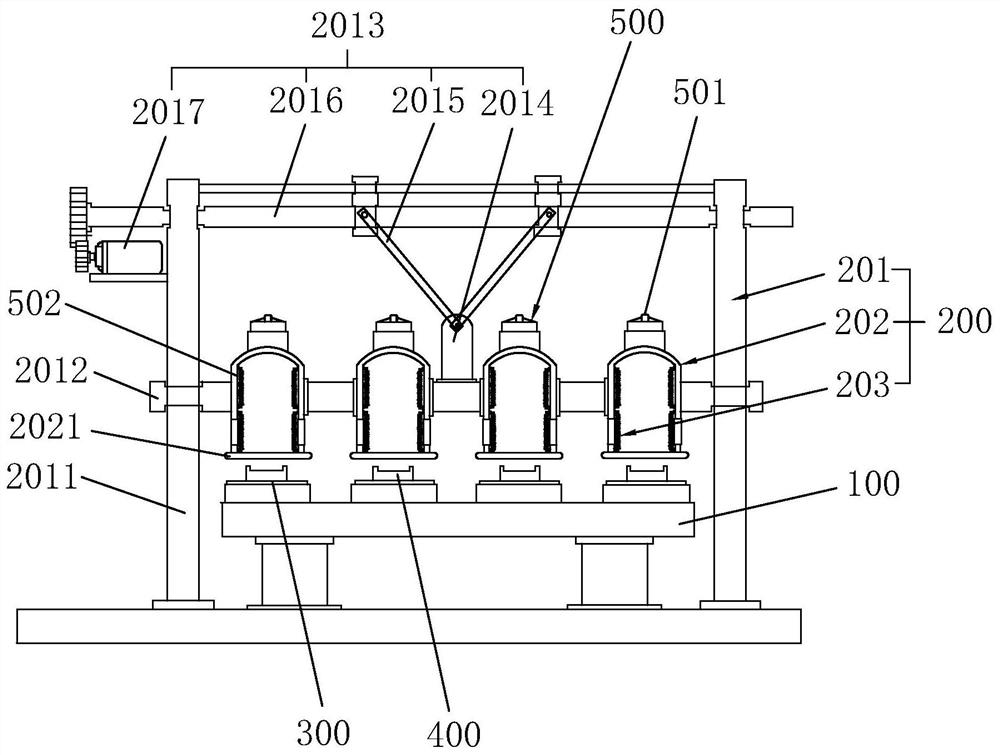

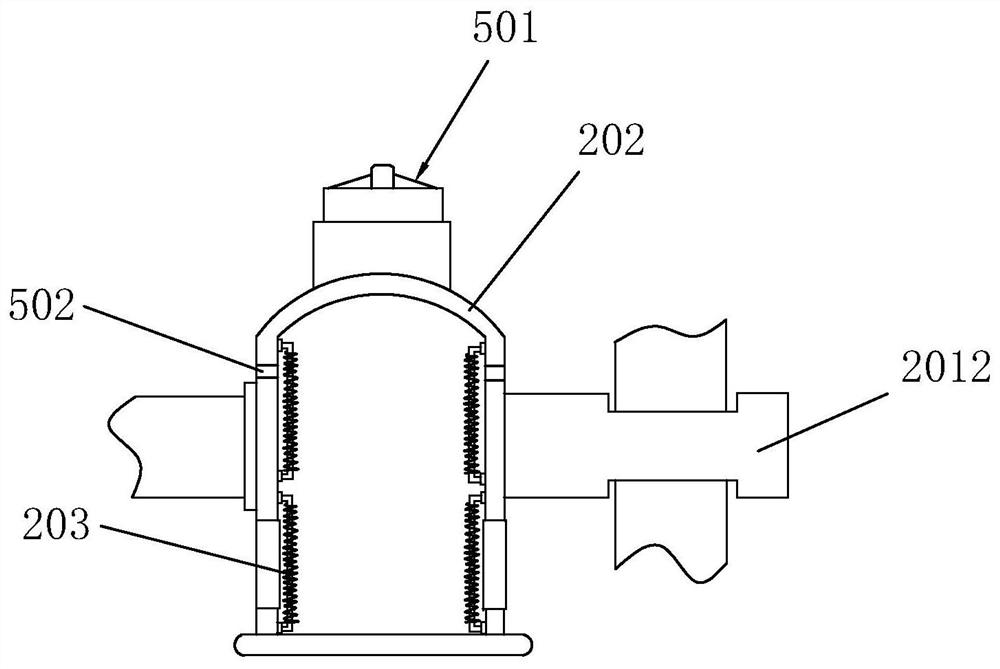

[0034] A production and spraying equipment for column-type electric porcelain insulators, combined with figure 1 and figure 2 It can be seen that the spraying workbench 100 and the spraying device 200 are included, the spraying workbench 100 is used to place products, and the spraying device 200 sprays the products on the spraying workbench 200 .

[0035] In this embodiment, in order to realize the one-to-one spraying method, the specific solution is as follows: a sealing plate 300 is provided on the spraying workbench 100 . Spraying device 200 is set to be made up of three parts of driving assembly 201, spraying container 202 and spraying head 203, and driving assembly 201 and spraying container 202 drive are connected, and driving assembly 201 drives spraying container 202 to move back and forth, and one end of spraying container 202 has an open end, and on the opening end A sealing ring 2021 is provided, and the sealing ring 2021 abuts against the sealing plate 300 to sea...

Embodiment 2

[0042] A column-type electric porcelain insulator production spraying equipment, this embodiment scheme is the same as the finishing structure principle of Embodiment 1, the difference is that the spraying container 202 and the sealing plate 300 are moved and assembled along the horizontal direction.

Embodiment 3

[0044] A column-type electric porcelain insulator production spraying equipment, the plan of this embodiment is the same as the finishing structure principle of the first embodiment, the difference is that the spraying container 202 and the sealing plate 300 are moved and combined along the inclined direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com