Powder feeding and brushing equipment for energy-saving lamp tube

A lamp tube and powder brushing technology, applied in the field of lighting, can solve the problems of relying on manual operation and low efficiency, and achieve the effect of simplifying work intensity and difficulty, improving work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

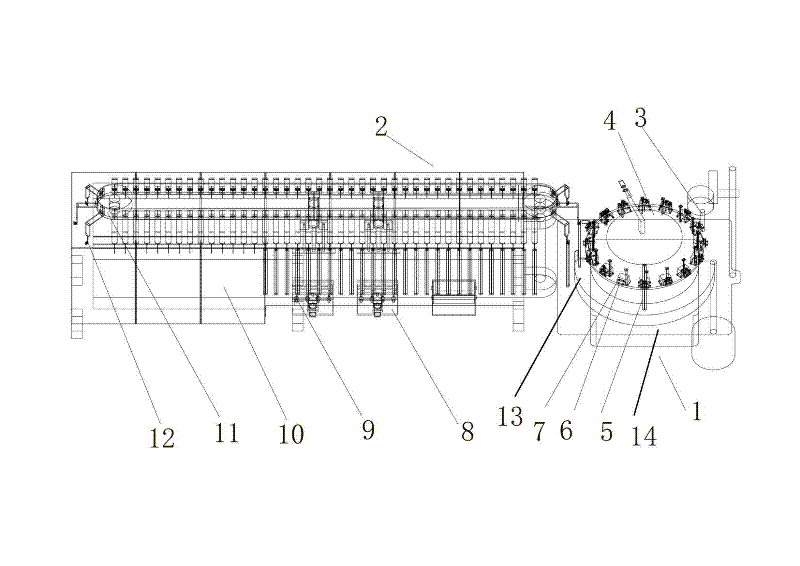

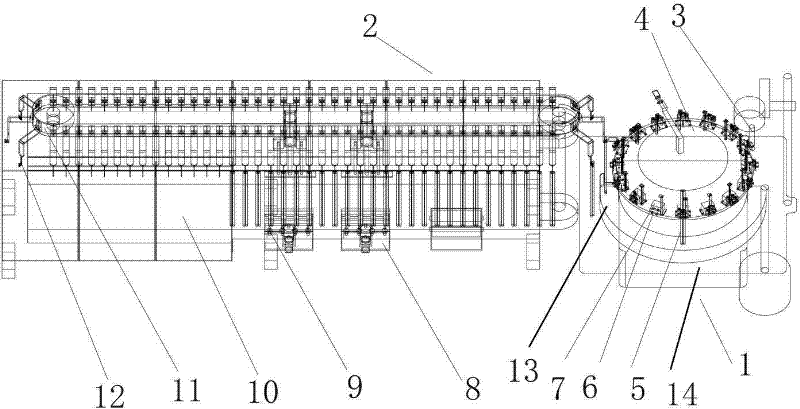

[0016] This embodiment includes a powder coating device 1 and a powder brushing device 2. After being powdered in the powder coating device 1, the lamp tube 5 is hung on the lamp tube hook 12 of the powder brushing device 2 and enters the powder brushing device.

[0017] The powder coating equipment 1 includes a base 14, on which a circular conveyor belt 4 is provided. The circular conveyor belt 4 is evenly provided with the first-type lamp holders 3, and the circular conveyor belt 4 runs step by step under the drive of a motor. , The distance of each advancement is the distance between two adjacent first-type lamp holders 3, so that each first-type lamp holder 3 corresponds to a working position; one of the working positions is provided with The delivery pipe 3 and the valve, the delivery pipe 3 is used to contain the liquid containing phosphor; the lamp tube fixing seat includes a first base and a gripper 6 fixed on the first base, and the gripper 6 can clamp the lamp tube 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com