Method for packaging LED illuminating device

A technology of LED lighting and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of LED lighting devices such as large volume, excessive glare, complex structure, etc., and achieve the advantages of reducing heat conduction process, beautiful appearance, and simple packaging process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

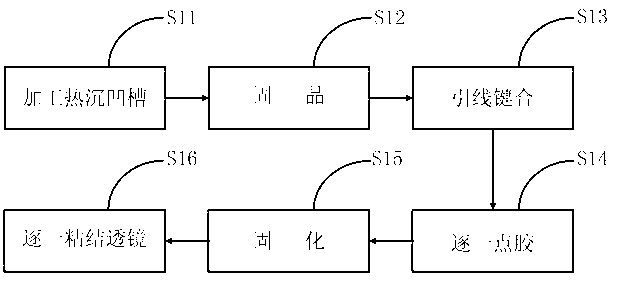

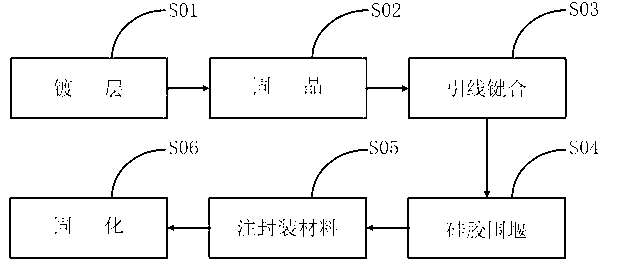

Method used

Image

Examples

Embodiment 1

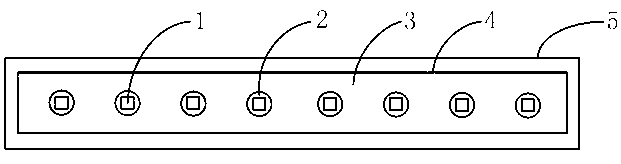

[0037] Such as image 3 As shown, it is a structural schematic diagram of a strip-shaped LED lighting device realized by the packaging method of the present invention.

[0038] The substrate 5 is made of a material with high thermal conductivity; the LED chip 1 is bonded with silver glue and fixed on the crystal-bonding position on the substrate 5 with the coating 2; the silica gel 4 is coffered on the substrate 5; the packaging material 3 is coated on The substrate 5 completely covers the LED chips 1 and is bonded to the substrate 5 .

[0039] Among them, the packaging material 3 is made of fluorescent powder mixed with glue, which has good fluidity, high refractive index, and high temperature resistance. The coffered silica gel 4 ensures the stability of its shape and position, and the formed fluorescent glue layer is flat. , the thickness is uniform and uniform, and no other medium is produced between the LED chip 1 and the interface loss of light is reduced.

Embodiment 2

[0041] Such as Figure 4 As shown, it is a structural schematic diagram of a circular LED lighting device realized by the packaging method of the present invention.

[0042] It is roughly the same as Embodiment 1, except that the circuit wiring on the substrate 5 is different, the shape of the substrate 5 is circular, the shape of the cofferdam of the silica gel 4 is also circular, and the packaging method is completely the same.

[0043] The above-mentioned embodiment 1 and embodiment 2 realize the integrated packaging of multiple LED chips on one circuit board, reduce the secondary optical lens to one, and cooperate with the mirror-like coating to enhance reflection and improve light extraction efficiency; no need for single-point glue point by point , with a higher yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com