Encapsulating structure for lighting LED lamp strip

A technology of LED light bar and packaging structure, which is applied in the direction of electrical components, electric solid devices, circuits, etc., which can solve the problems of increasing secondary optical structure materials and manufacturing costs, increasing the difficulty of heat dissipation of LED lamps, and reducing the luminous rate of LED lamp beads, etc. , to achieve the effect of eliminating the need for secondary optical design, improving the heat dissipation conditions of the die, saving materials and production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

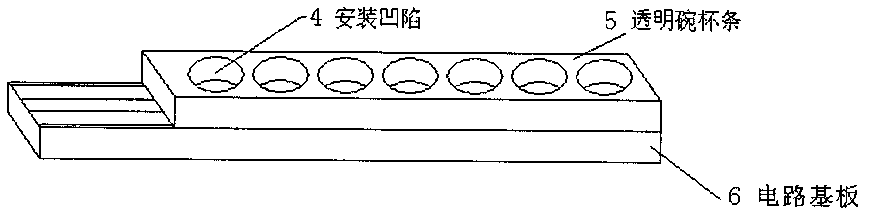

[0028] The present invention will be further described below in conjunction with drawings and embodiments. see Figure 4 , the present invention is provided with a circuit substrate 6 , a transparent cup bar 4 , several LED tube cores 7 , fluorescent colloid 8 , and an outer package 10 .

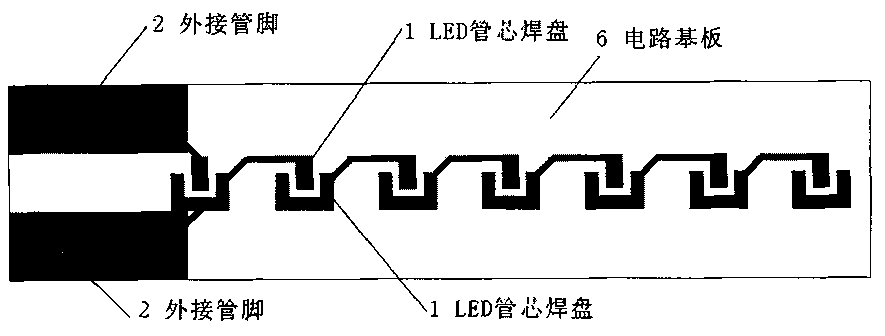

[0029] see figure 1 , The circuit can basically be made of PCB circuit board, aluminum substrate or ceramic substrate, and the pads and corresponding connected wires are arranged on the circuit substrate. The circuit substrate is also designed with external pins to facilitate the assembly of the finished product.

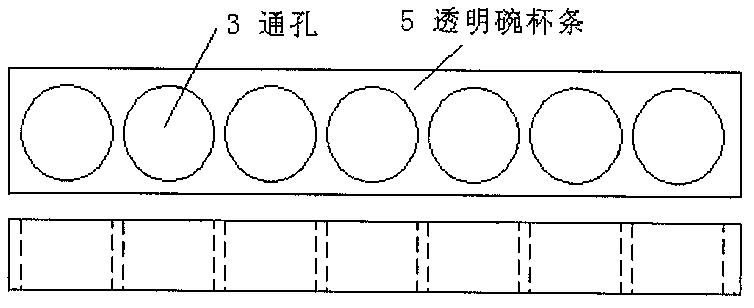

[0030] see figure 2 , The transparent cup bar is made of a transparent material, such as plexiglass, and several through holes are processed on the cup bar.

[0031] see image 3 , the base of the light bar is composed of a circuit substrate and a transparent cup strip. The through holes on the cup strip are in the same position as the pads on the circuit substrate, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com