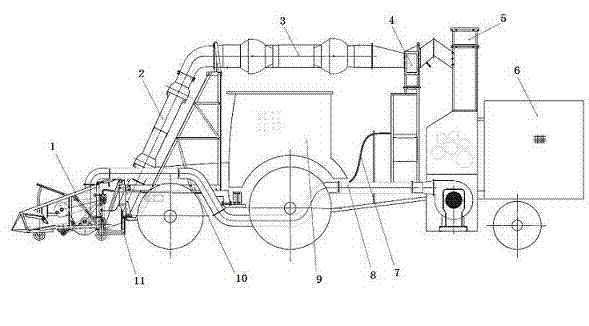

Harvesting table of cotton harvester

A cotton harvesting and cotton technology, applied to harvesters, picking machines, agricultural machinery and tools, etc., can solve problems such as gushing blockage, easy blockage of feeding inlet, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

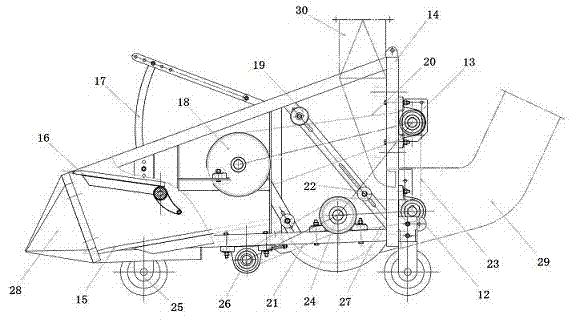

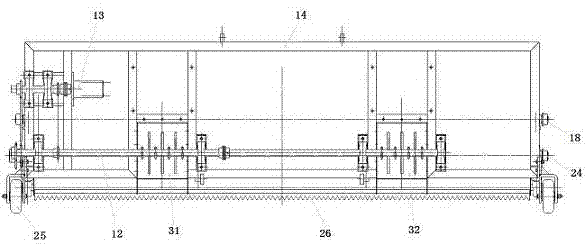

[0028] The assembly and transmission method of the harvesting platform is: the conveying auger 24 is installed on the harvesting platform frame 14 through the mounting holes on the outer spherical bearings at both ends with bolts, and the lower row of comb teeth 15 is installed on the harvesting platform through bolts. On the frame 14, the cotton pulling roller 18 is installed on the harvesting platform frame 14 through the mounting holes on the outer spherical bearings at both ends with bolt connection, and the anti-pulling roller 26 is installed with bolt connection through the mounting holes on the outer spherical bearings at both ends. On the harvesting platform frame 14, the upper row of comb teeth 16 adopts bolt connection to be installed on the gathering platform frame 14 through the threaded holes at both ends, and the crop divider 28 is installed on the gathering platform frame 14 by bolt connection, The cotton roller 12 is installed on the harvesting platform frame 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com