A heat treatment method for obtaining a three-state structure through high-temperature deformation of tc4-dt titanium alloy in the two-phase region

A TC4-DT, high-temperature deformation technology, applied in the field of heat treatment, can solve the problems of difficult matching of plasticity and strength-toughness, damage tolerance performance, loss of plasticity, etc., and achieve good comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

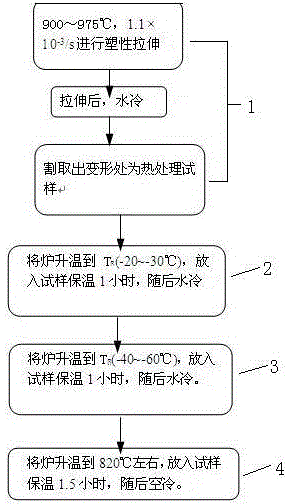

[0025] Such as figure 1 As shown in the present invention, a heat treatment method for obtaining a three-state structure through high-temperature deformation of the TC4-DT titanium alloy in the two-phase region, the specific steps are as follows:

[0026] The first step: heat treatment sample preparation process (1). TC4-DT first passes through the two-phase zone temperature, 1.1×l0 -3 / s for plastic stretching, immediately take out the water cooling after the sample is broken; cut out the deformed area as the heat treatment sample;

[0027] The second step: the first heavy heat treatment (2). The first reheat treatment is selected as solid solution in the two-phase region, the purpose is to completely change the stretched structure of TC4-DT, make it into β phase and β transformation structure, and retain a certain amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com