Electrode for a DBD plasma process

A technology of dielectric barrier discharge and plasma, which is applied in the field of electrodes and coating large pieces of glass, can solve the problems of different expansion coefficients, difficulty in manufacturing and use, and achieve the effect of large elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

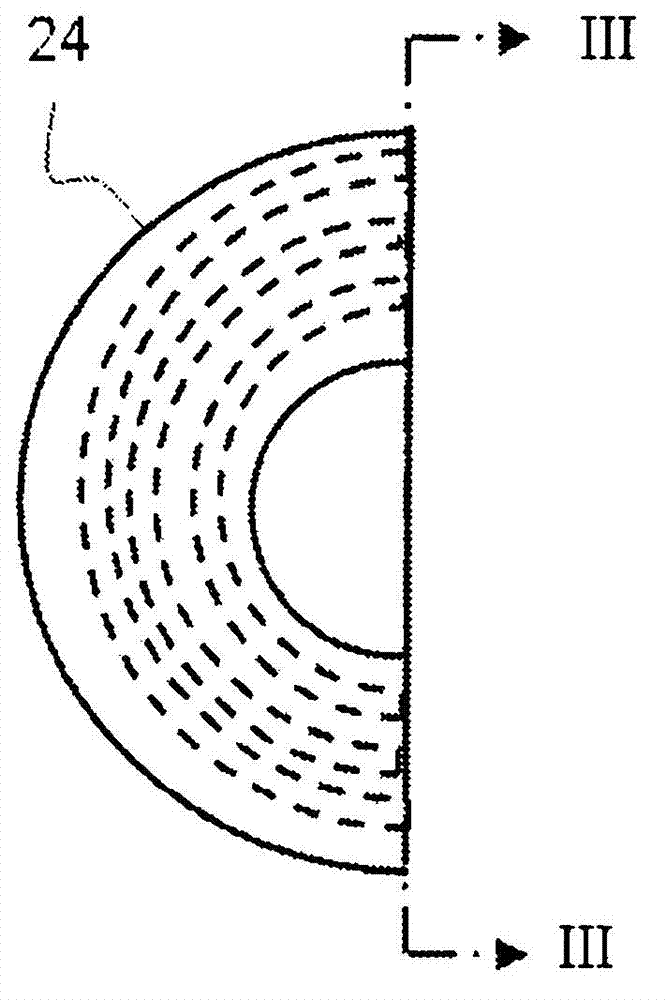

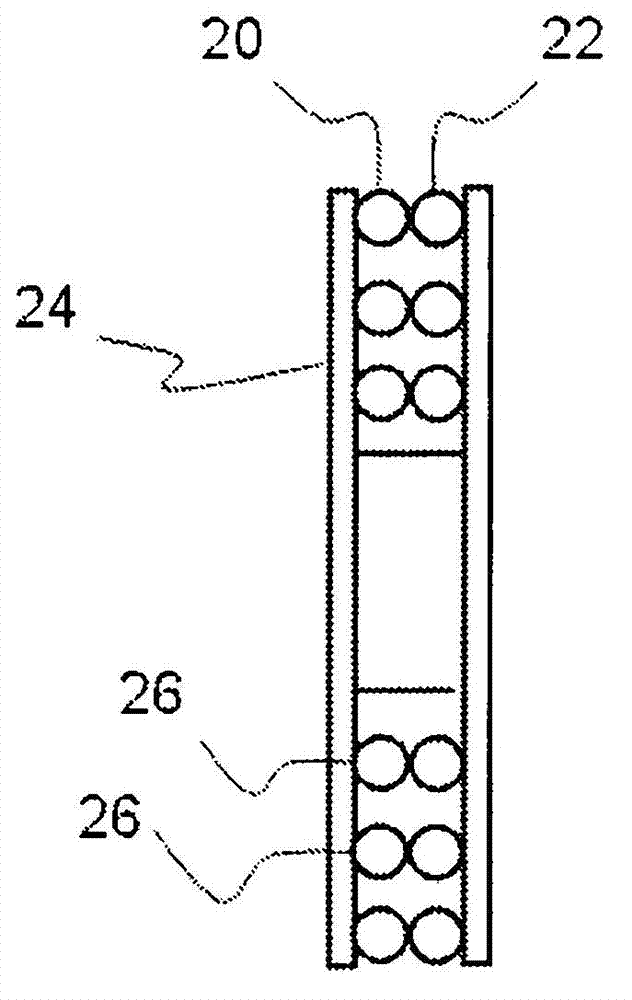

[0049] The figures are not drawn to scale (in particular, thicknesses are exaggerated to facilitate understanding). Generally, similar elements are labeled with similar reference numerals in the drawings.

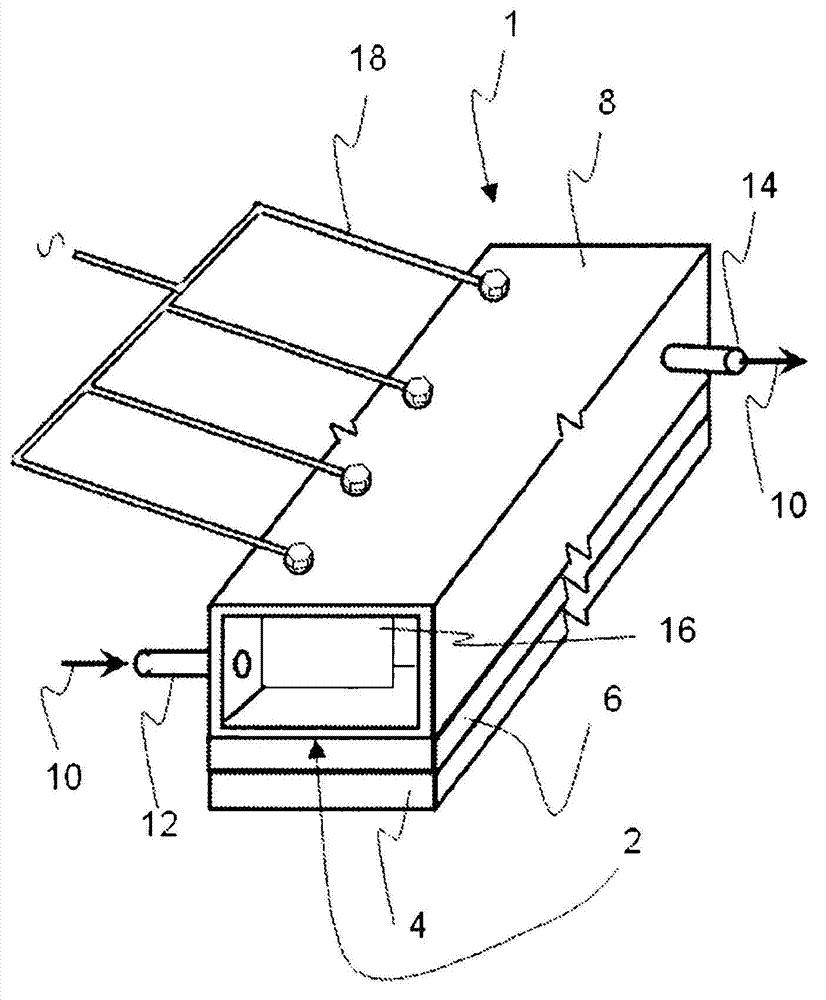

[0050] figure 1is a schematic diagram of an electrode of the present invention. Such an electrode 1 , which has been developed especially for the surface treatment and / or coating of large pieces of glass, can typically be close to four meters long and is therefore shown truncated.

[0051] Such an electrode 1 is usually installed facing another electrode, and due to the application of an ultra-high-voltage high-frequency electric field between these electrodes, a plasma is generated in the gap separating these two elements. The "working" part of the electrode, i.e. the part facing the second electrode 36, is shown here with a substantially planar surface 2 facing downwards ( Figure 4 ). One of the problems faced by those skilled in the art is the danger of sparks in io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com