Removal method for photoetching coating on carbon-containing porous material substrate

A porous material and coating technology, applied in the field of photolithographic coating removal, can solve problems such as substrate damage, and achieve the effects of increasing removal capacity, overcoming slow removal speed, and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

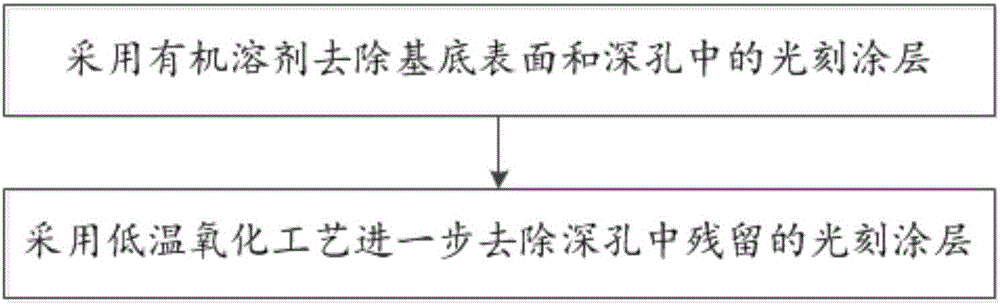

[0021] like figure 1 Shown, a kind of removal method for the photolithography coating of carbonaceous porous material substrate comprises the steps:

[0022] Step 1, using an organic solvent to remove the photoresist coating on the substrate surface and deep holes; the photoresist coating includes a photoresist coating and an antireflection coating.

[0023] The specific implementation of the step 1 is, at room temperature, the organic solvent is sprayed onto the substrate surface, and the organic solvent is evenly covered on the substrate surface by rotating the substrate, and the photoresist coating on the substrate surface and deep holes is dissolved in the organic solvent. After the solvent is removed, the orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com