Method for measuring compartment pressure and device

A chamber pressure and pressure technology, applied in the field of devices for measuring fascia chamber pressure, can solve problems such as inability to directly measure pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

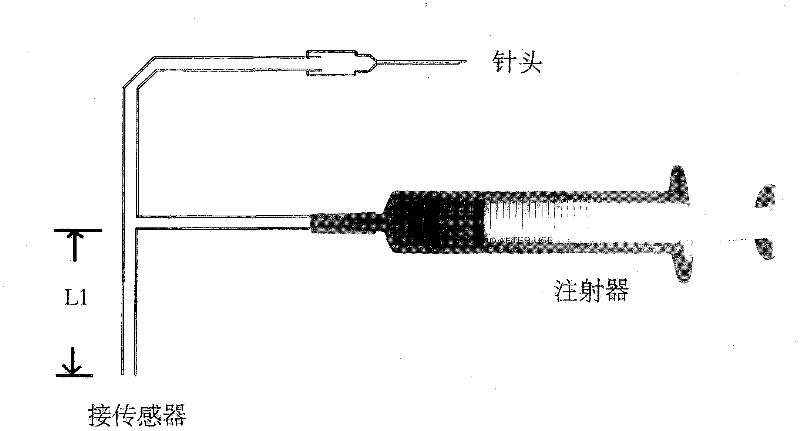

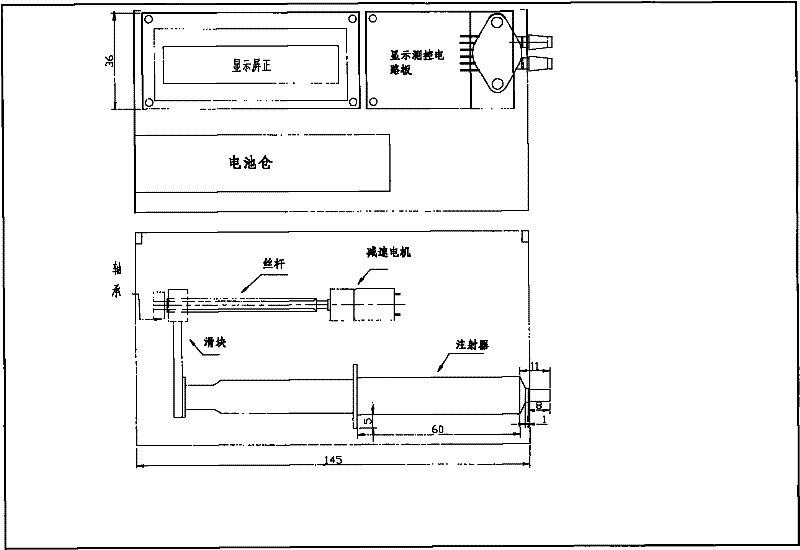

[0015] The specific working process is as follows: Turn on the power switch, display LOGO, and automatically reset at the same time. At this time, the voltage self-check will be carried out. If the battery is insufficient, "low power" will be displayed, and the slider will move to the farthest end, stop after touching the in-position switch and open the warehouse Cover, connect the 5ml syringe with saline pumped to the tee, and connect the other end of the tee to the sensor interface, put the syringe, close the cover, press the button to enter the exhaust state, after the motor stops, pierce the needle into the fascia Press the button to start the measurement, display "start", and display the pressure value after a few seconds. If it exceeds the set range (4KPa) or there is an abnormal pressure, it will alarm. After 12 consecutive measurements, it will automatically reset.

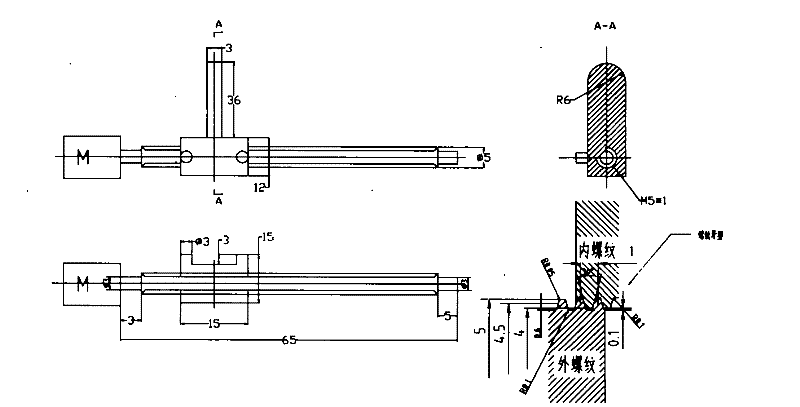

[0016] figure 1 The thread of the middle screw adopts trapezoidal thread, the pitch is 1mm, and it is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com