Dirt removal device for fine grid

A technology of fine grid and filter screen, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problem of intercepting fine debris stuck in the grid gap, so as to avoid mechanical failure and often adjust the workload, Easy to clean and separate, simplify the effect of driving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

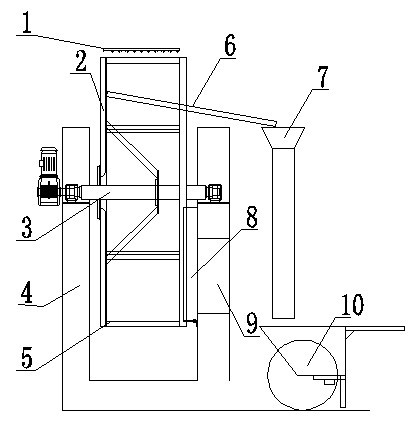

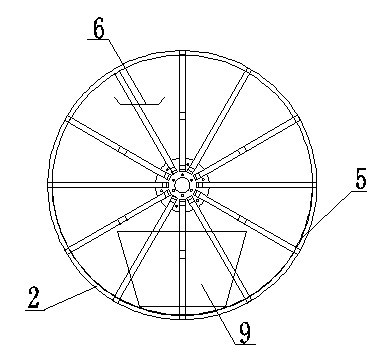

[0018] Embodiment: Referring to the accompanying drawings, the fine grid decontamination device of the present invention includes a cover-shaped drum 2 with one end closed and the other end open Φ2.5 meters, and there is a stainless steel wire filter screen with an inserted piece assembled aperture of 10-20 mesh on the peripheral surface of the drum 5. There are spraying and flushing nozzles 1 on the outer circumference (or inner circumference) above the drum, and there is a slag discharge tank 6 that protrudes obliquely from the drum opening at the upper inner part of the drum. The slag trolley 10 (both are installed separately, can be omitted). The cover-shaped filter drum is supported by a central shaft 3 and placed on a U-shaped water tank 4 (wherein the lower half is immersed in water), and the axial width of the filter drum is slightly smaller than the width of the U-shaped tank (it can rotate in the U-shaped tank), and The rotation is driven by the central axis 3. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com