Selective catalytic reduction device for flue gas denitrification and application method thereof

A selective, flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of catalyst clogging, catalyst poisoning, etc., reduce manufacturing costs, increase market share, and facilitate manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

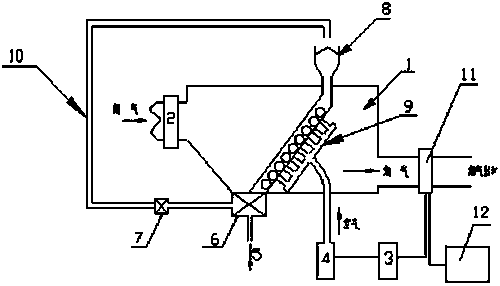

[0050] A selective catalytic reduction flue gas denitrification device, its structure schematic diagram is as follows figure 1 As shown, 1 is the NOx removal device, 2 is the NOx content detector, 3 is the electrical sensor for NOx concentration detection, 4 is the ventilation device, 5 is the fly ash discharge port, 6 is the catalyst / fly ash separation device, and 7 is the Catalyst regeneration instrument, 8 is the catalyst adding funnel, 9 is the ventilation plate, 10 is the catalyst delivery pipe, 11 is the automatic valve, 12 is the upper computer, 13 is the porous bed layer for laying the catalyst;

[0051] The ventilation plate 9 is placed under the porous bed 13 of the catalyst, and the ventilation plate 9 and the porous bed 13 of the catalyst are installed in the NOx removal device and are at a 30° angle to the horizontal direction of the NOx removal device 1. o ~45 o The included angle; ventilation plate 9 and the porous bed layer 13 interface schematic diagram of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com