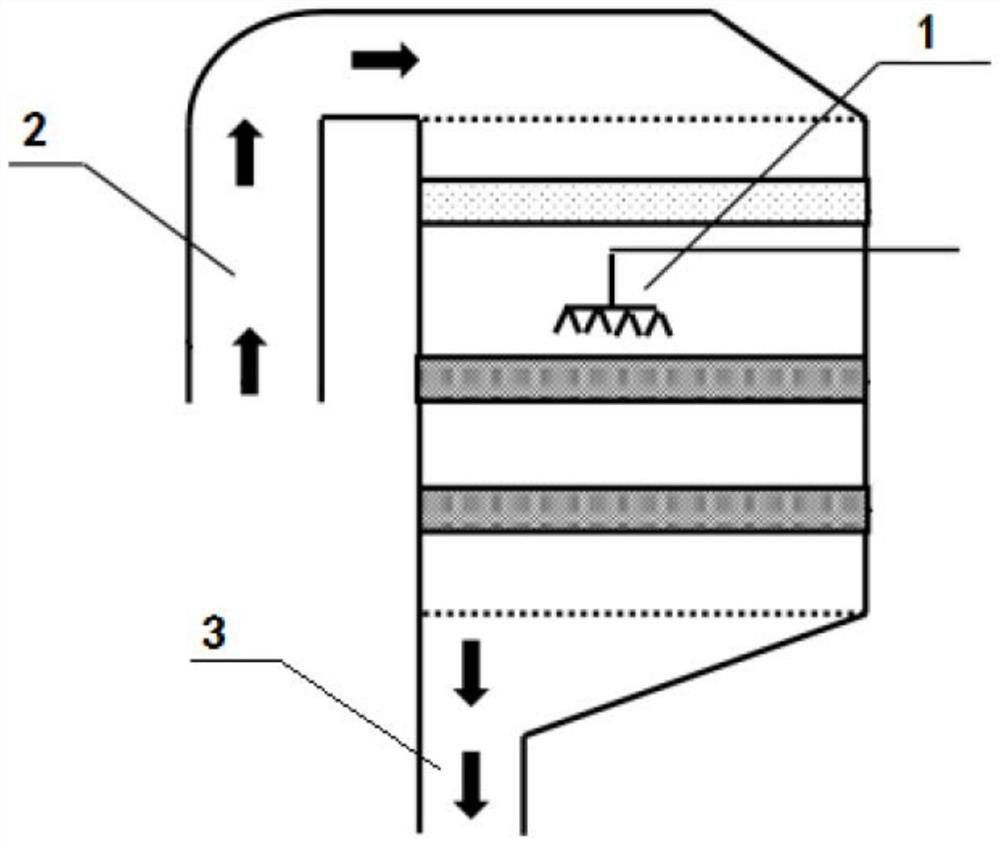

SCR (Selective Catalytic Reduction) reactor, catalyst and preparation method of catalyst

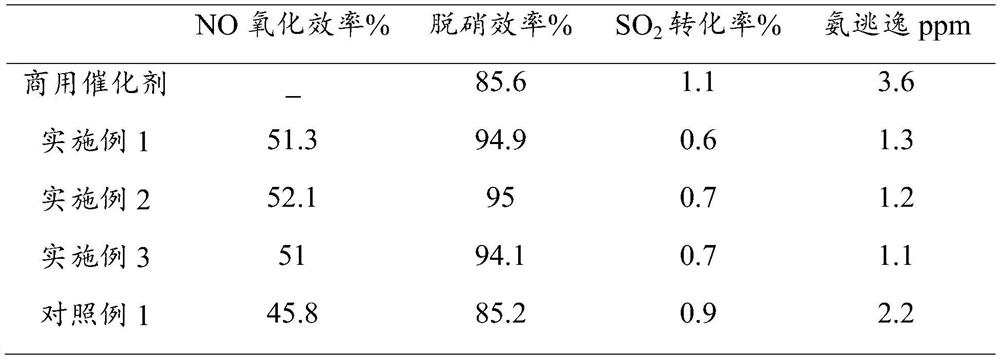

An SCR reactor and catalyst technology, applied in the field of flue gas denitrification, can solve the problems of reduced work efficiency, increased ammonia injection, catalyst deactivation, etc., to reduce the conversion generation rate, reduce the generation of NH4HSO4, reduce the generation of SO3 Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

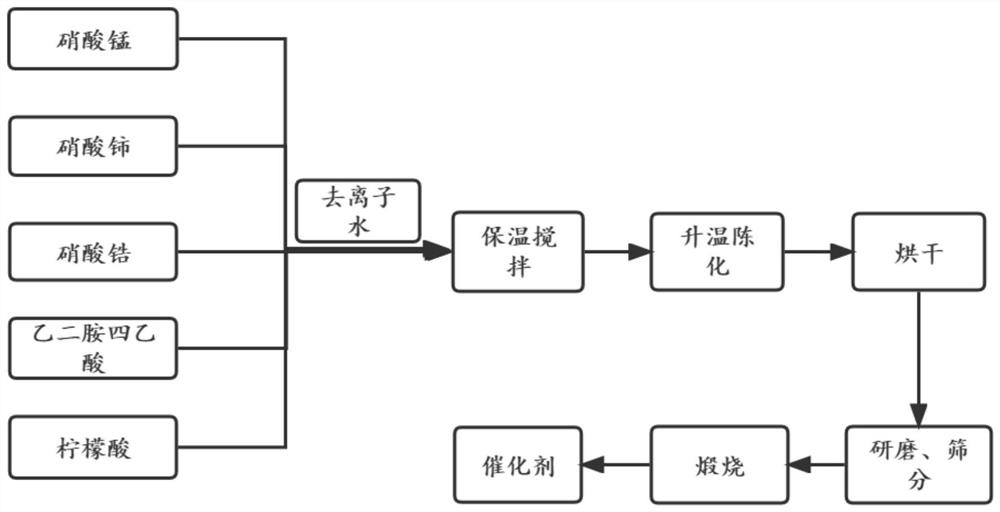

[0048] S11, dissolving manganese nitrate, zirconium nitrate and cerium nitrate with a molar ratio of 1:1:2 in water to form a metal salt solution;

[0049] S12. Add tetraethylamine oxalate and citric acid in a molar ratio of 1:1.5 to the metal salt solution, and keep stirring at 80°C for 2 hours. The molar ratio of amine and water remains unchanged, at this time, the temperature is raised to 95°C until a gel is formed;

[0050] S13. Put the gel in an oven at 120°C for 3 hours, grind and sieve the catalyst particles of 200-500 μm, then place the powder in a muffle furnace, and calcinate at 700°C for 3 hours in an air atmosphere to obtain sulfur-resistant Mn doping Ce / Zr solid solution catalyst.

Embodiment 2

[0052] S21, dissolving manganese nitrate, zirconium nitrate and cerium nitrate with a molar ratio of 1:1:2 in water to form a metal salt solution;

[0053] S22. Add tetraethylamine oxalate and citric acid in a molar ratio of 1:1.5 to the metal salt solution, and heat and stir at 70°C for 3 hours. After the heat preservation and stirring are completed, metal nitrate, citric acid, and tetraethyl oxalate The molar ratio of amine and water remains unchanged, at this time, the temperature is raised to 100°C until a gel is formed;

[0054] S23. Put the gel in an oven at 110°C for 4 hours, grind and sieve the catalyst particles of 200-500 μm, then place the powder in a muffle furnace, and calcinate at 800°C for 2 hours in an air atmosphere to obtain sulfur-resistant Mn doping Ce / Zr solid solution catalyst.

Embodiment 3

[0056] S31, dissolving manganese nitrate, zirconium nitrate and cerium nitrate with a molar ratio of 1:1:2 in water to form a metal salt solution;

[0057] S32. Add tetraethylamine oxalate and citric acid in a molar ratio of 1:1.5 to the metal salt solution, and heat and stir at 90°C for 1 hour. After the heat preservation and stirring are completed, metal nitrate, citric acid, and tetraethyl oxalate The molar ratio of amine and water remains unchanged, and at this time, the temperature is raised to 90°C until a gel is formed;

[0058] S33. Put the gel in an oven at 130°C for 2 hours, grind and sieve the catalyst particles of 200-500 μm, then place the powder in a muffle furnace, and calcinate at 600°C for 2 hours in an air atmosphere to obtain sulfur-resistant Mn doping Ce / Zr solid solution catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com