Aluminum alloy die casting piece trimming die with smooth cut

A technology of aluminum alloy and die-casting parts, which is applied in the field of stamping dies. It can solve the problems of difficult disassembly of guide posts and guide sleeves, laborious product removal, and rough incisions, so as to avoid surface damage, facilitate disassembly and assembly, and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

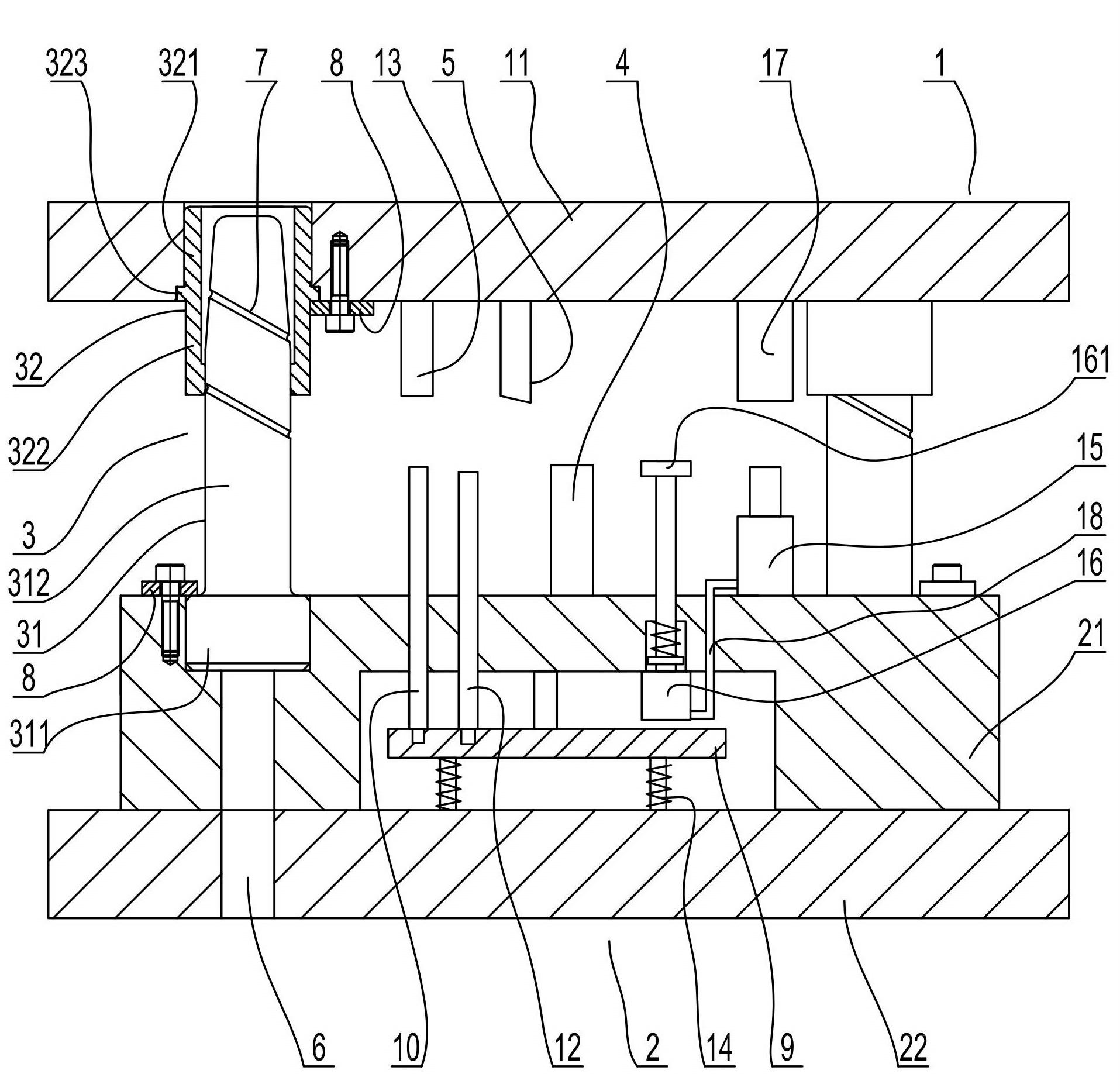

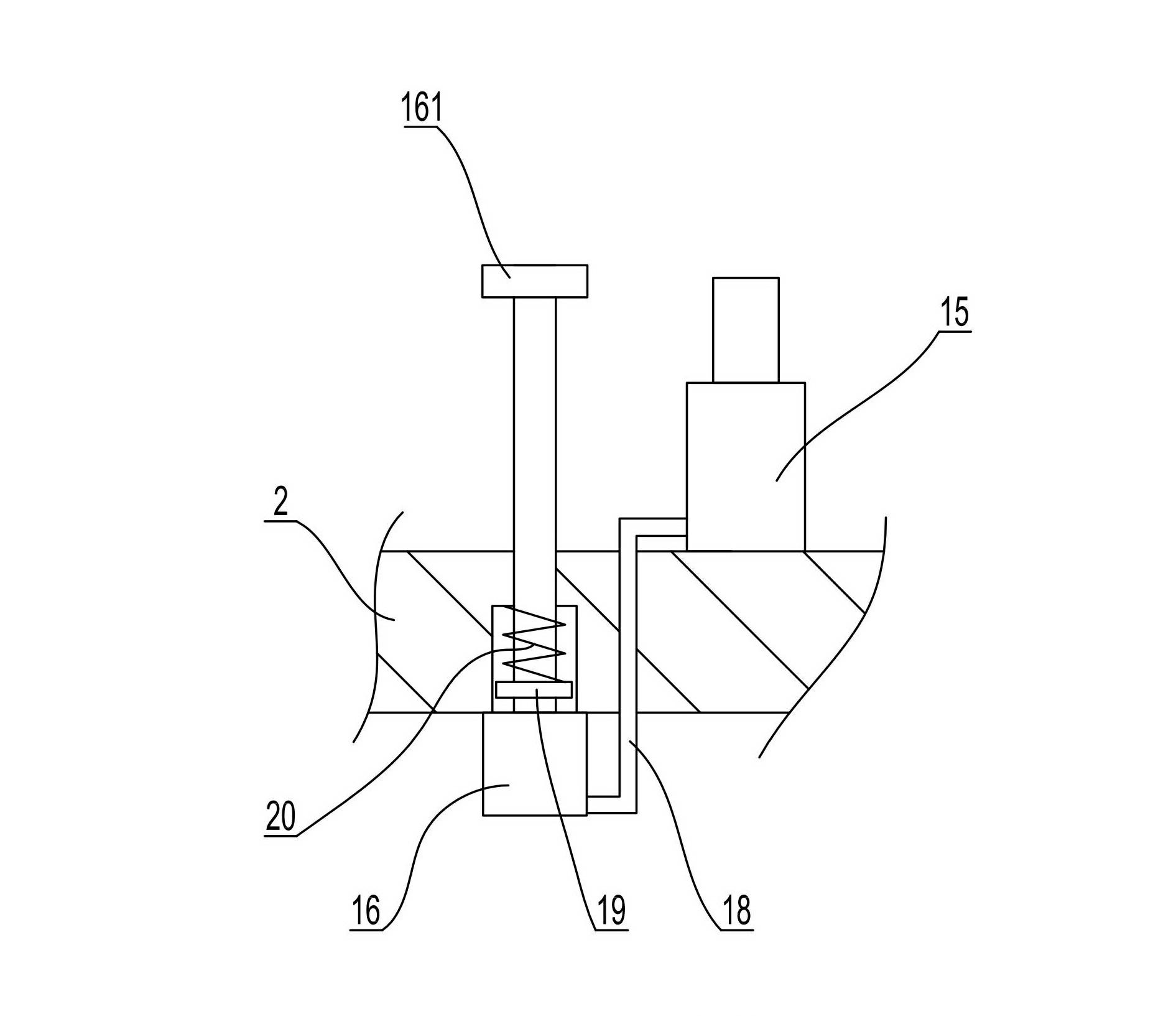

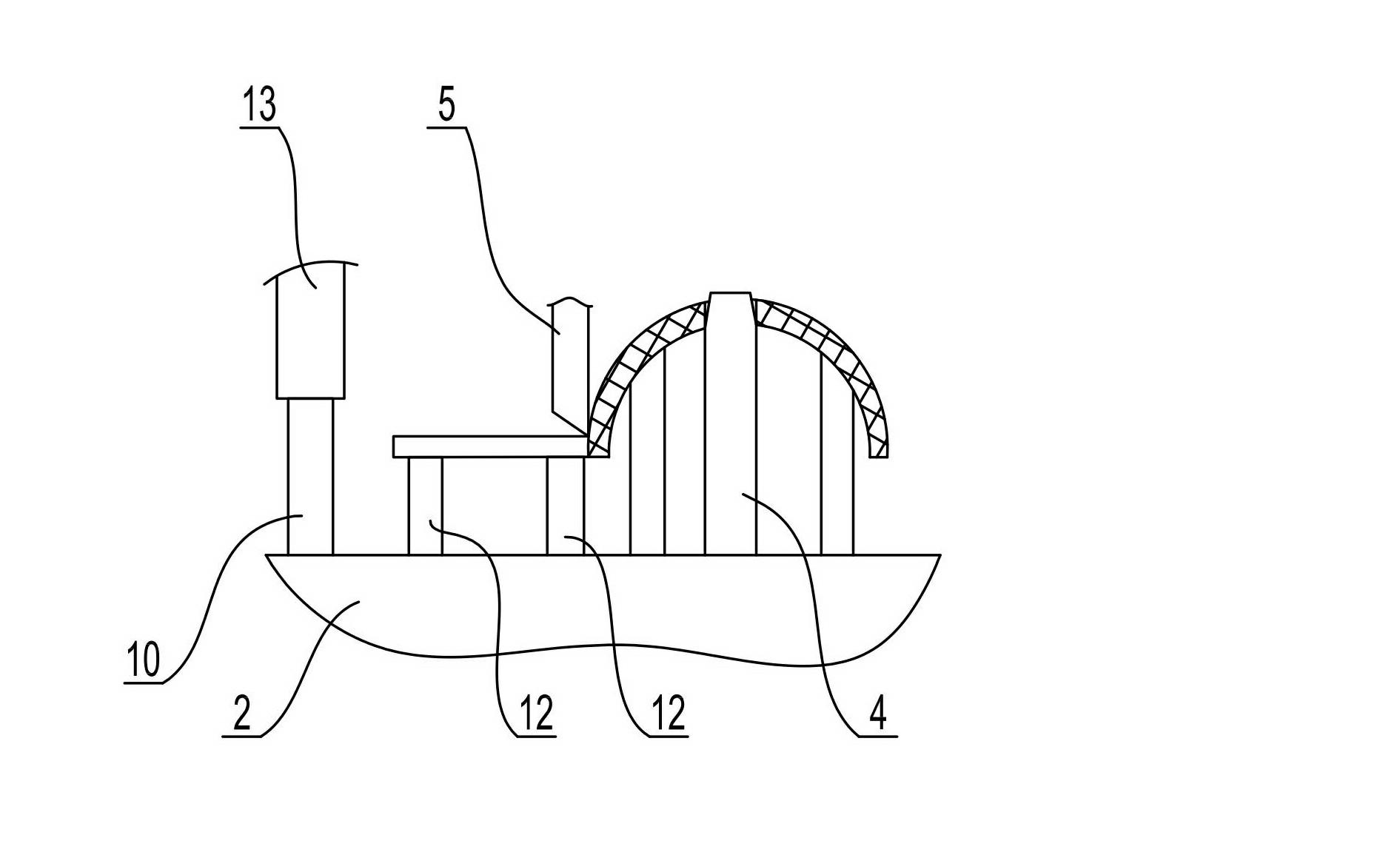

[0030] Embodiment 1: as figure 1 In the shown embodiment, a trimming die of an aluminum alloy die casting with a smooth cut includes an upper die 1, a lower die 2, a guiding structure 3 arranged between the upper die and the lower die, and a product positioning structure arranged on the lower die 4 and the trimming knife edge 5 provided on the upper die, wherein the guide structure includes guide posts 31 arranged at the four corners of the lower die and four guide sleeves 32 correspondingly arranged on the upper die, of course, depending on the size of the die , two guide posts and guide sleeves can also be set on one side only.

[0031] The guide post is a stepped shaft, which includes a guide post fixing section 311 and a guide post guide section 312 slidingly fitted with the guide sleeve. hole, the fixed section of the guide post is embedded in the fixing hole, and at the same time, a dismounting hole 6 that penetrates to the bottom of the lower platen is provided on the ...

Embodiment 2

[0037] Embodiment 2: as Figure 4 As shown, in the guide structure 3 of an aluminum alloy die-casting edge trimming die with a smooth cut in this embodiment, the guide post 31 also includes a guide post fixing section 311 and a guide post guide section 312, and the guide sleeve 32 also includes a guide post 32. The difference between the sleeve fixing section 321 and the guide sleeve guiding section 322 is that the diameter of the guide post fixing section is smaller than the diameter of the guide post guiding section, thereby forming a step, and the guide post fixing section is embedded on the lower mold and forms a tight fit. , the above steps play a limiting role. Similarly, the diameter of the fixed section of the guide sleeve is smaller than that of the guide section of the guide sleeve, so that the fixed section of the guide sleeve is embedded on the upper mold and forms a tight fit. Of course, in order to make the fixing of the guide post reliable, connecting bolts can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com