Method and device for forming sheet metal by high velocity impact of bullets

A sheet metal, high-speed impact technology, applied in metal sheet forming, based on the field of high-speed impact forming, can solve the problem of inaccurate control of the strain rate of the processed material, achieve automatic production, good repeatability, and high-speed pulse impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

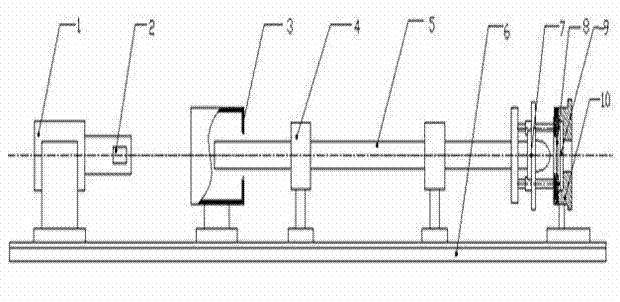

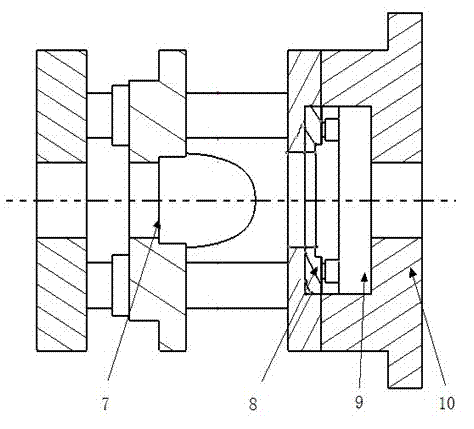

[0014] see Figure 1-2 The device for high-speed impact sheet metal forming of the present invention includes a light gas compression launch system, a bullet recovery chamber 3, a support 4, a single-axis high-speed impact rod 5, a base 6 and a forming and clamping system, and the entire device adopts a transverse structure. Among them, the light gas compression launch system provides high-speed pulse power for the whole device, and is composed of a light gas compression gun 1 and bullets 2. The bottom of the light gas compression gun 1 is fixed on the base 6, and the light gas compression gun 1 is equipped with bullets 2 . A bullet recovery chamber 3 is set at a distance directly in front of the bullet 2, and the bullet after impact is recovered immediately. The bottom of the bullet recovery chamber 3 is fixed on the base 6. The rear end of the horizontally arranged uniaxial high-speed striking rod 5 stretches in the bullet recovery chamber 3, and the front of the uniaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com