Method for synchronously forming backing ring of plate heat exchanger through constrained tube axial compression

A plate heat exchanger and heat exchanger technology, applied in the direction of metal processing equipment, etc., can solve problems affecting product quality, affecting product appearance, increasing the difficulty of heat exchanger maintenance, etc., to simplify the processing process, improve processing efficiency and forming quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A method for synchronously forming the lining ring of a plate heat exchanger with constrained tube axial pressure, including the following steps:

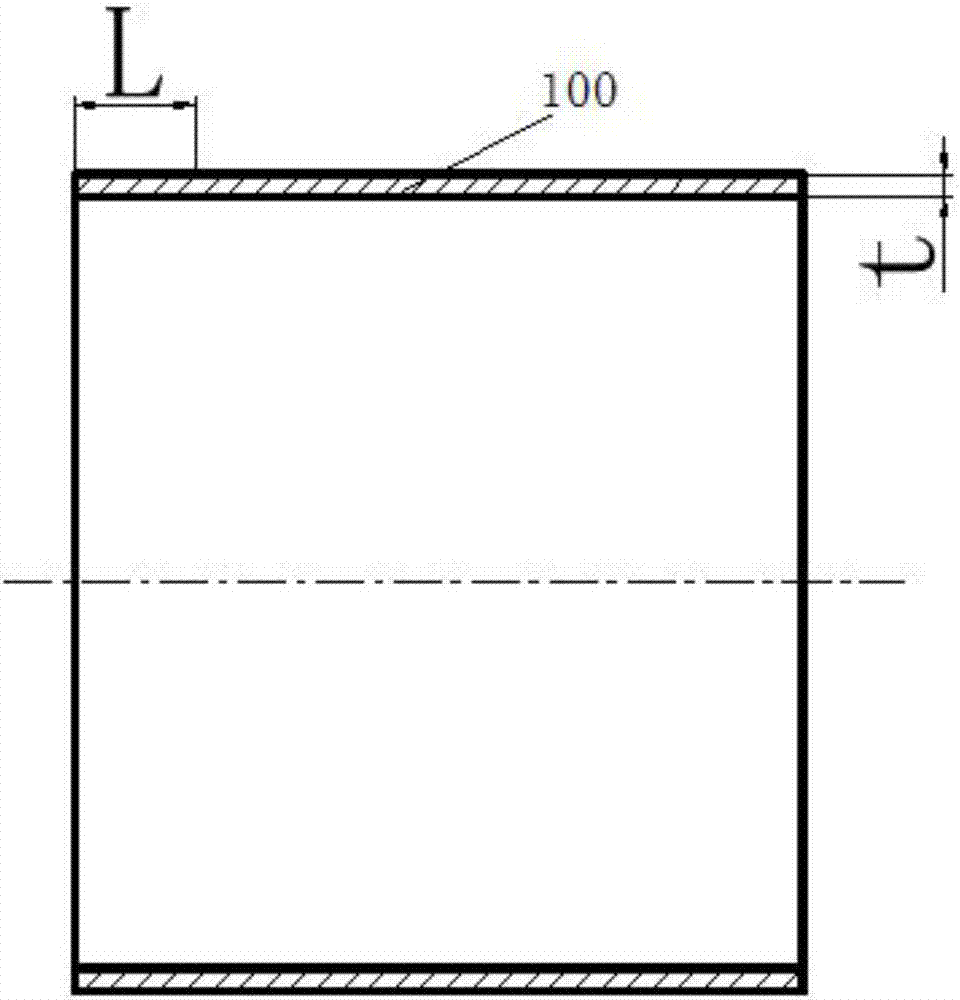

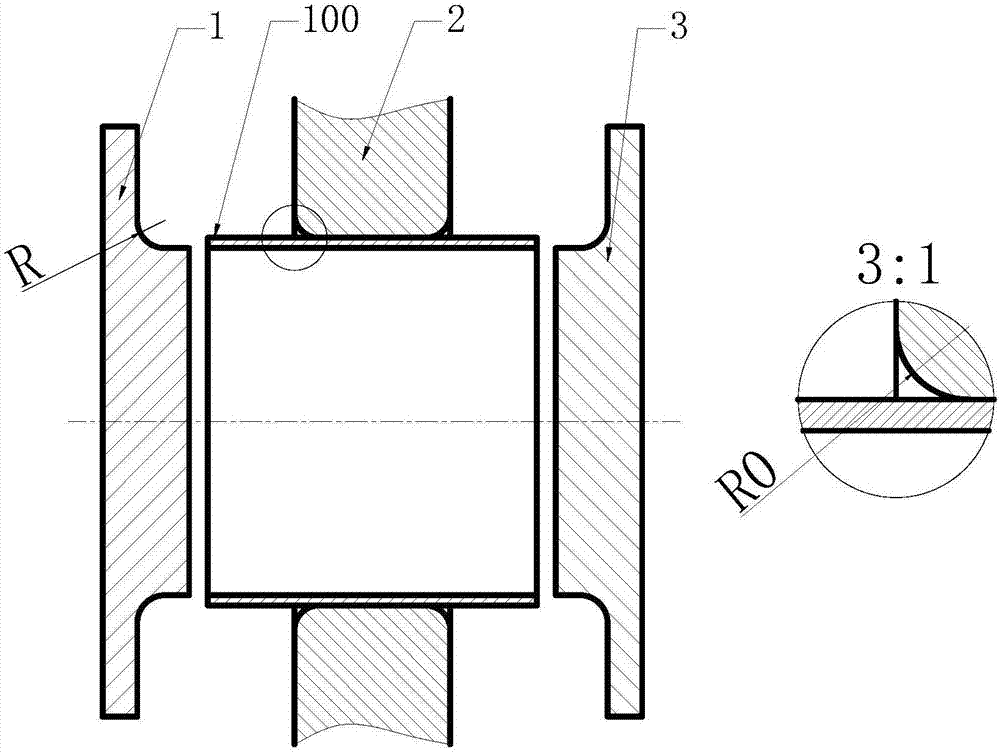

[0026] 1), refer to figure 1 and figure 2 , the pipe 100 is assembled in the inner hole of the plate heat exchanger 2, the fillet of the inner hole of the plate heat exchanger 2 is R0, the length of the free end of the pipe 100 is L, and the thickness is t, and the plate heat exchanger 2 is fixed, Ensure that the position of the pressure plate 2 of the plate heat exchanger is in the middle of the first tube axial pressure punch 1 and the second tube axial pressure punch 3, and constrain the outer wall of the pipe 100;

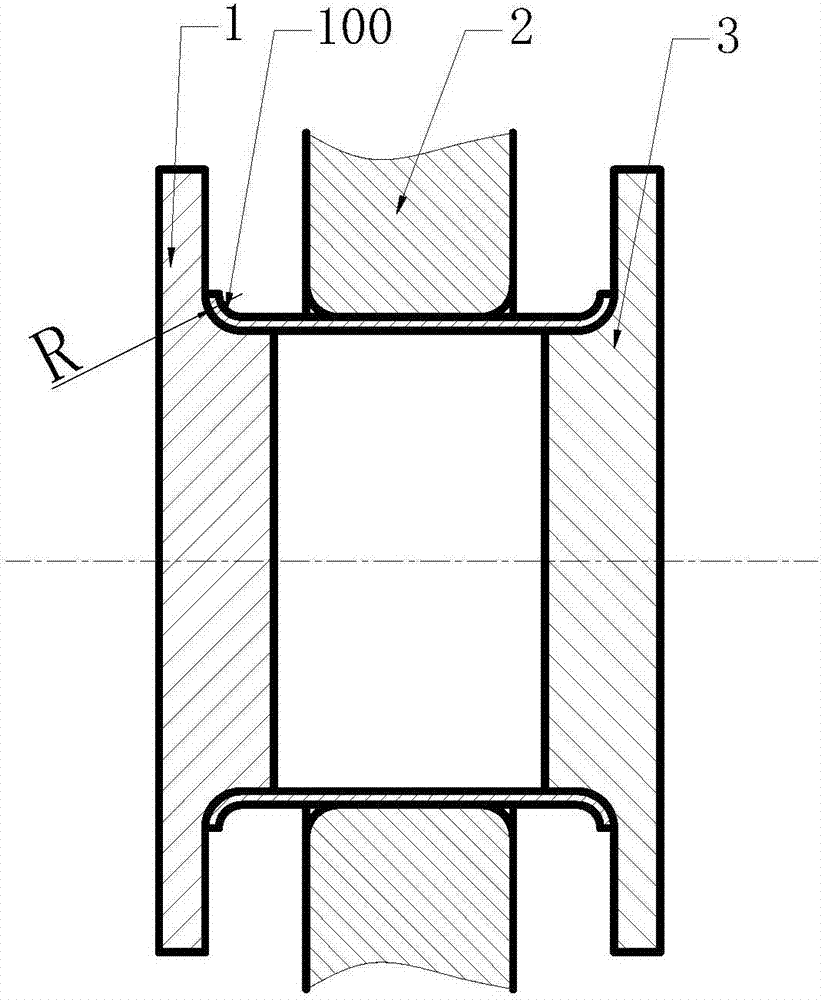

[0027] 2), refer to image 3 , the first tube axial pressing punch 1 and the second tube axial pressing punch 3 are fed towards each other along the axial direction at the same speed, and the free end of the pipe 100 is connected to the first tube axial pressing punch 1 and the second tube a...

Embodiment 2

[0031] Embodiment 2: A method for synchronously forming the lining ring of a plate heat exchanger with constrained tube axial pressure, including the following steps:

[0032] 1), refer to figure 1 and figure 2 , the pipe 100 is assembled in the inner hole of the plate heat exchanger 2, the fillet of the inner hole of the plate heat exchanger 2 is R0, the length of the free end of the pipe 100 is L, and the thickness is t, and the plate heat exchanger 2 is fixed, Ensure that the position of the pressure plate 2 of the plate heat exchanger is in the middle of the first tube axial pressure punch 1 and the second tube axial pressure punch 3, and constrain the outer wall of the pipe 100;

[0033] 2), refer to image 3 , the first tube axial pressing punch 1 and the second tube axial pressing punch 3 are fed towards each other along the axial direction at the same speed, and the free end of the pipe 100 is connected to the first tube axial pressing punch 1 and the second tube a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com