Nano-cluster-strengthened iron-base superalloy

An iron-based superalloy and nano-cluster technology, applied in the field of metal materials, can solve the problems of difficulty in controlling oxygen content, reducing bonding strength, and low density of molded green bodies at room temperature, so as to reduce the mechanical alloying process and high-temperature sintering process , Precise control of oxygen content, uniform distribution of solid dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

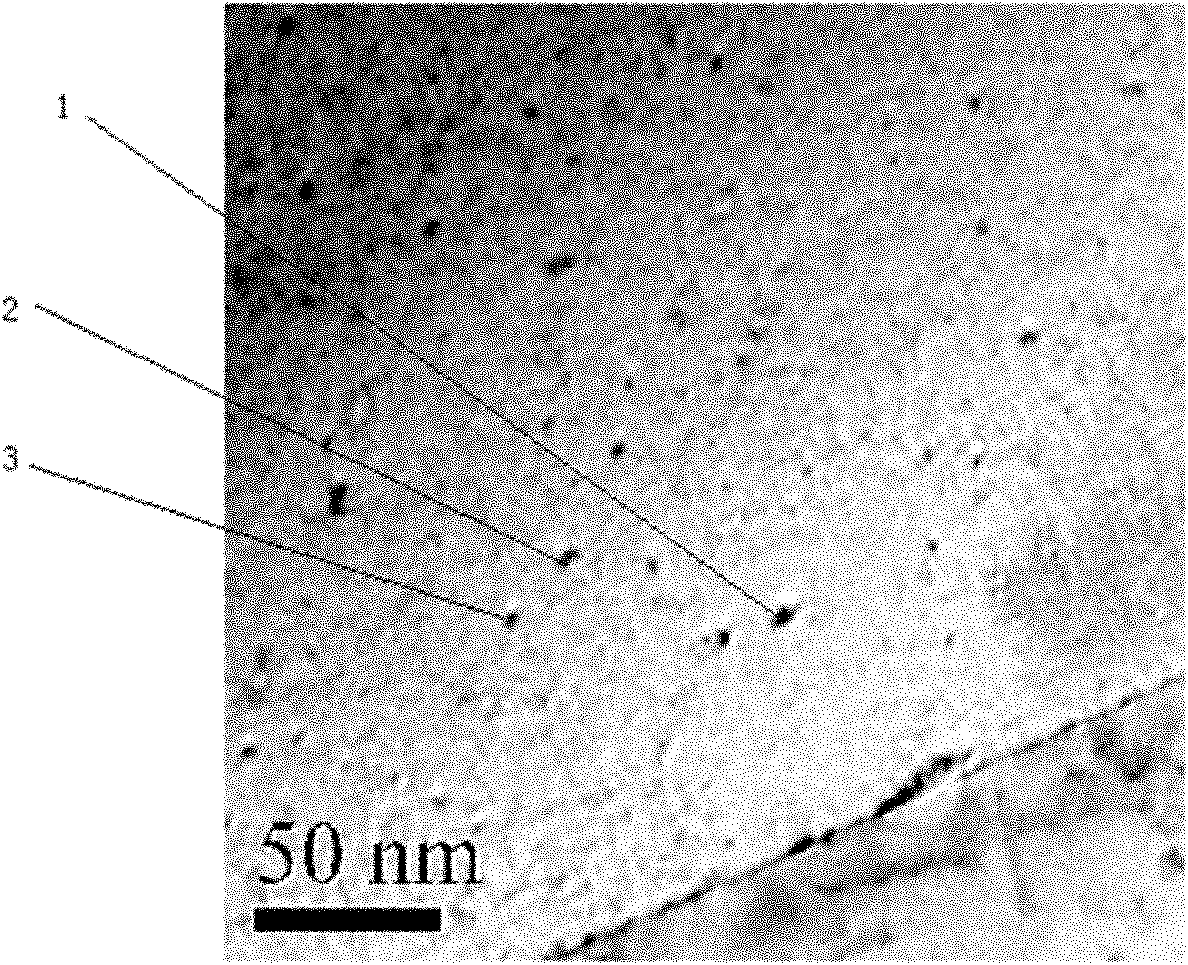

[0048] Example 1: A nanophase-strengthened iron-based superalloy whose composition is Fe-13.8Cr-3.1W-0.42Ti-0.27Y-0.08O (mass fraction%)

[0049] Select the gas-atomized Fe-13.8Cr-3.1W-0.42Ti-0.27Y-0.08O (mass fraction %) alloy powder with a particle size of ≤200 μm and an average oxygen content of 0.08% (mass fraction), and put it into the steel ladle , use a vacuum unit to vacuum degas the bag filled with powder, and the vacuum degree reaches 10 -2 Pa and continue to evacuate for more than 30min, then heat the enveloped powder to 150°C and continue to evacuate to 10 -2 After Pa, degassing for more than 60min, heat locally and rapidly at the part 40mm~60mm above the bottom of the exhaust pipe of the sheath, and hammer it quickly after heating to the temperature that can be completely welded by hammering, repeating several times to completely weld the inner wall of the exhaust pipe Close, remove the excess exhaust pipe, and use a welding machine to weld the exhaust pipe seal....

Embodiment 2

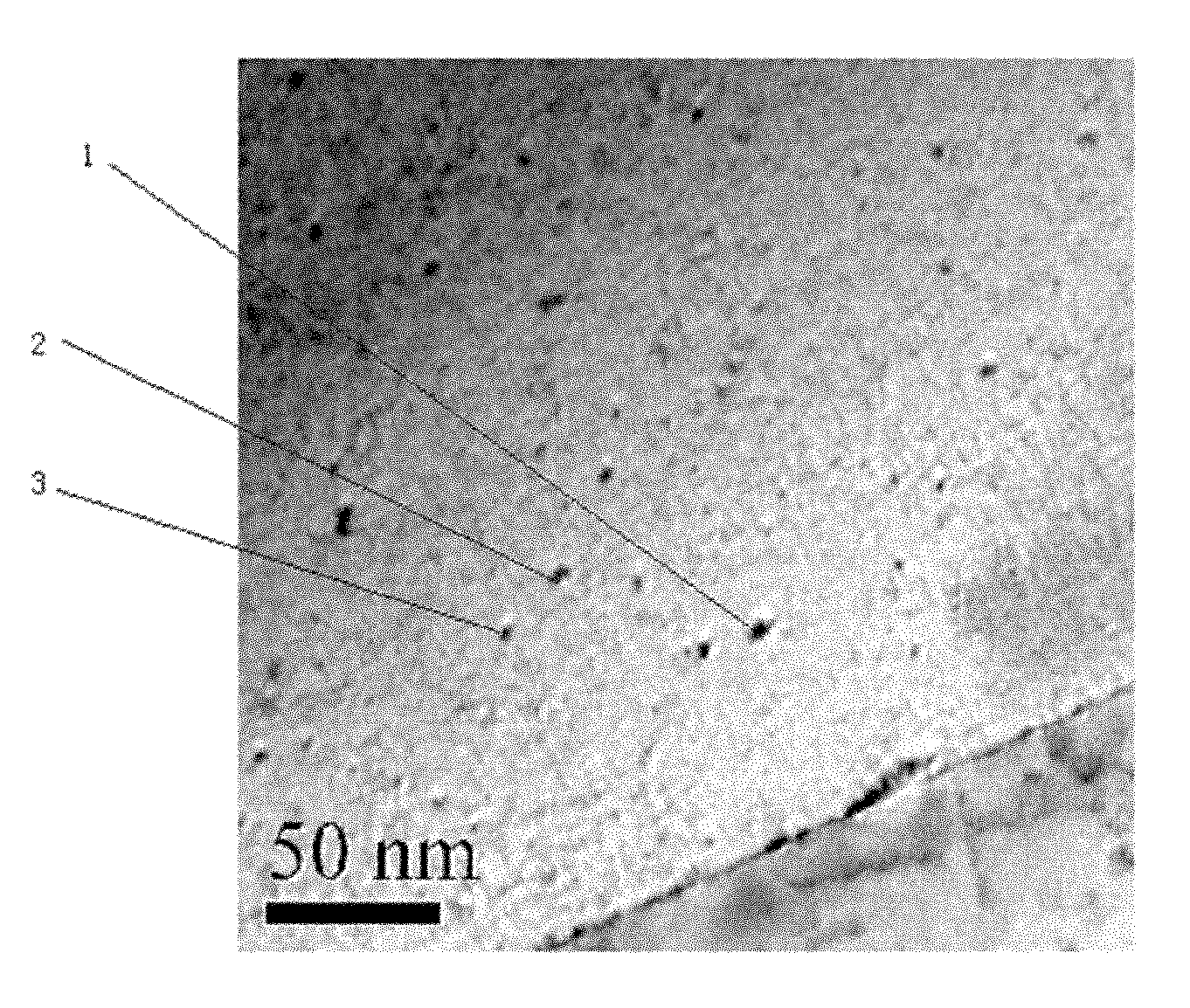

[0051] Example 2: A nanophase-strengthened iron-based superalloy whose composition is Fe-13.9Cr-2.6W-0.38Ti-0.32Y-0.11O (mass fraction%)

[0052]Select the gas atomized Fe-13.9Cr-2.6W-0.38Ti-0.32Y-0.11O (mass fraction %) iron-based alloy powder whose particle size is ≤200 μm and average oxygen content of 0.11% (mass fraction), and then according to the example The method and steps of 1 complete the sealing and welding of the sheathing powder, heating and heat preservation, smearing of graphite powder, and then extruding with an extrusion ratio of 9:1. After removing the sheathing, the resulting material has a density of 7.77×10 3 kg / m 3 , the relative density reaches more than 99%. After subsequent deformation and heat treatment, a nanocluster-strengthened iron-based superalloy is obtained.

Embodiment 3

[0053] Example 3: A nanophase-strengthened iron-based superalloy whose composition is Fe-14.5Cr-2.9W-0.45Ti-0.40Y-0.15 (mass fraction%)

[0054] Select the gas atomization Fe-14.5Cr-2.9W-0.45Ti-0.40Y-0.15O (mass fraction %) iron-based alloy powder whose particle size is ≤200 μm and average oxygen content of 0.2% (mass fraction), and then according to the example The method and steps of 1 complete the sealing and welding of the sheathing powder, heating and heat preservation, applying graphite powder, and then extruding with an extrusion ratio of 14:1. After removing the sheathing, the resulting material has a density of 7.78×10 3 kg / m 3 , the relative density reaches more than 99%. After subsequent deformation and heat treatment, a nanocluster-strengthened iron-based superalloy is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com