Full-automatic visual spot-welding robot

An automatic spot welding and fully automatic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. problems, to achieve the effect of reducing product defects, excellent sports performance, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

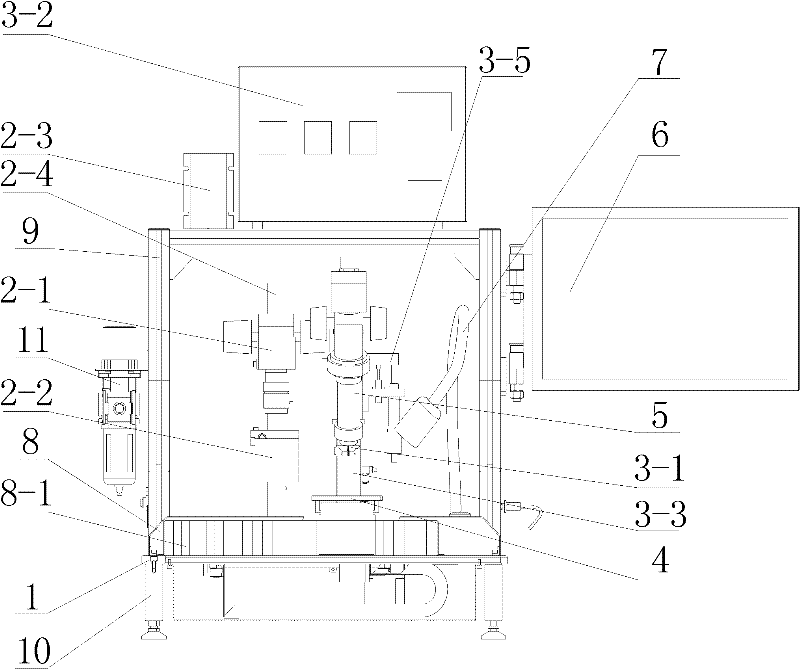

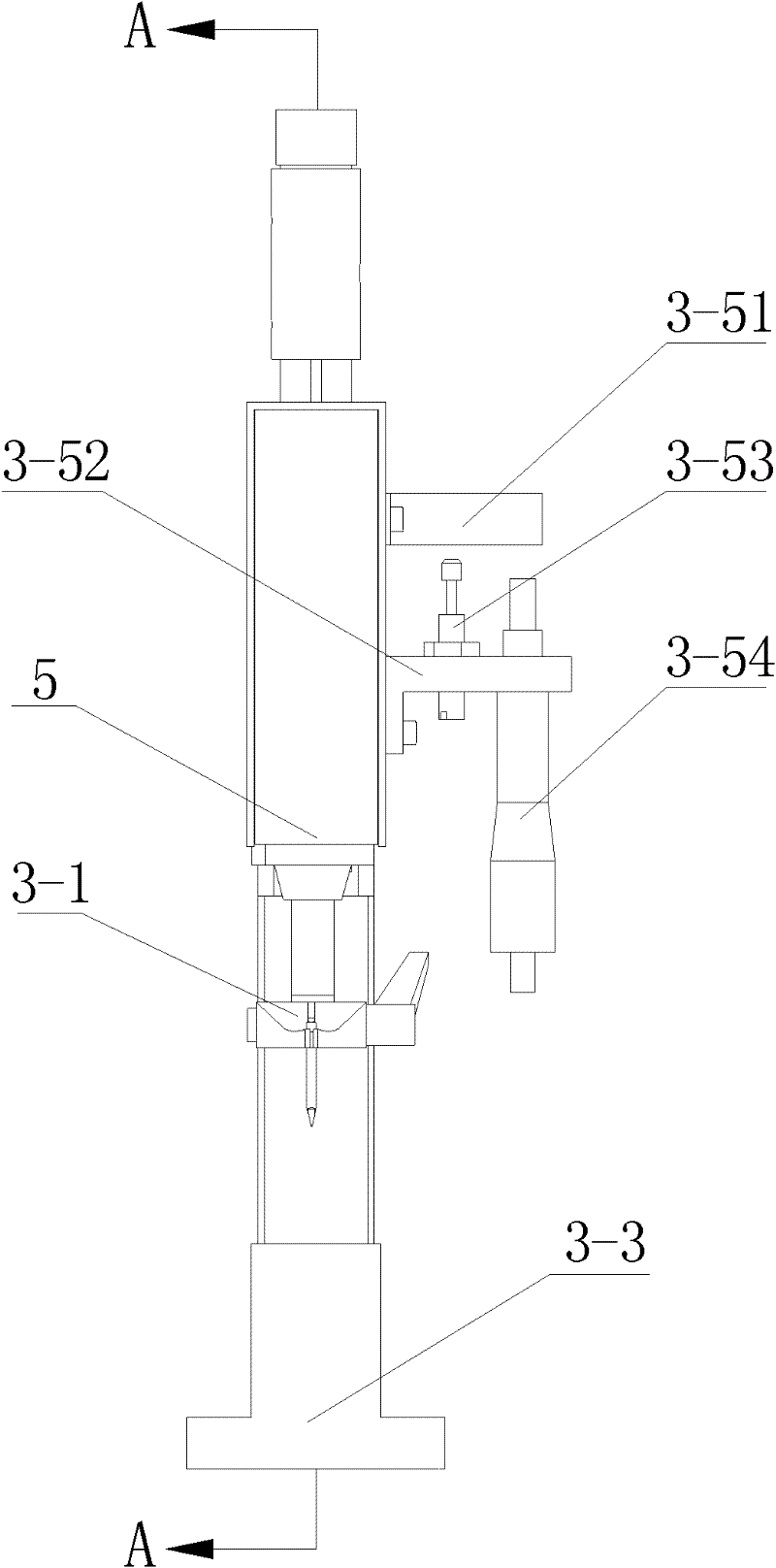

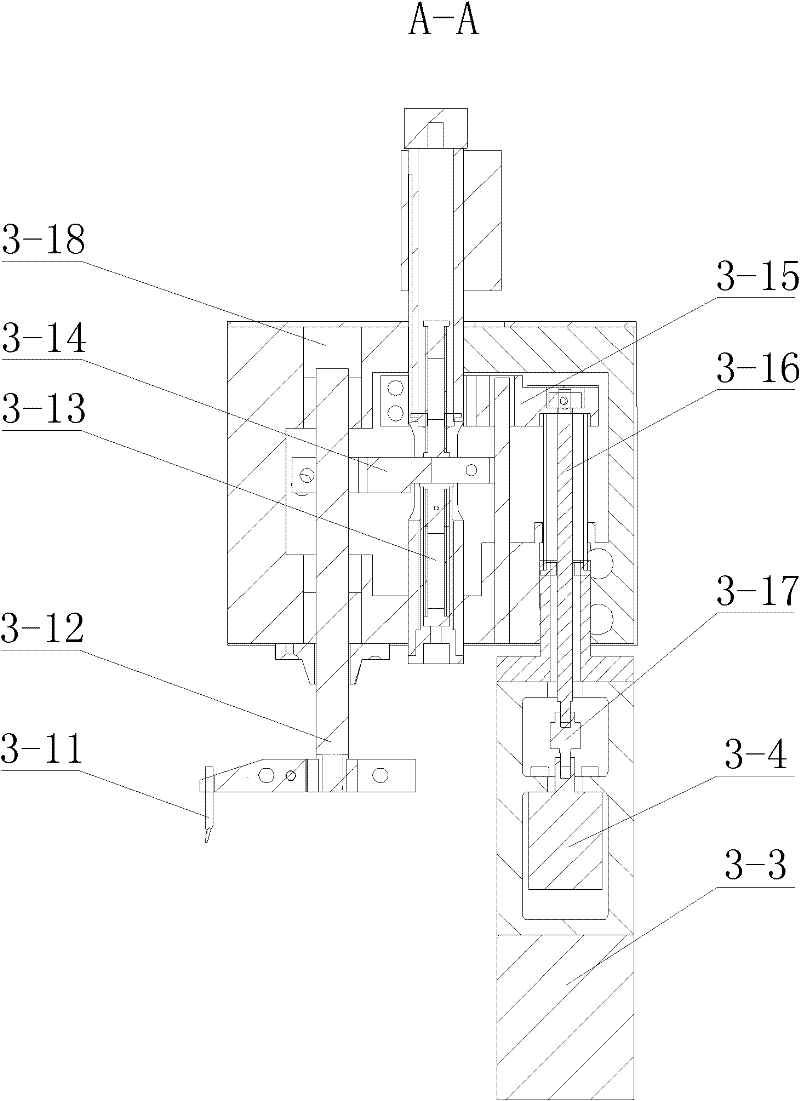

[0020] like Figure 1-Figure 3 A kind of fully automatic visual spot welding robot shown, comprises base plate mechanism 1, visual identification system, automatic spot welding system, two-dimensional motion platform system and is used for setting the industrial computer of visual parameter and data processing, described visual identification system, The automatic spot welding system, the motion platform system and the industrial computer are all arranged on the bottom plate mechanism 1 .

[0021] The visual recognition system includes an industrial camera 2-1, a light source 2-2 and a light source controller 2-3 for switching the light source 2-2 and adjusting the light intensity of the light source 2-2. The industrial camera 2-1 and the light source 2 -2 is connected to the bottom plate mechanism 1 through a lifting platform, the lifting platform is composed of a column 2-4 and two sliders arranged on the column 2-4, and the column 2-4 is fixedly connected to the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com