Modular combination crystal silicon multi-wire cutting waste mortar online recycling system

A multi-wire cutting and recycling technology, which is used in fine working devices, working accessories, and sediment separation by centrifugal force, etc., can solve the problem that waste mortar cannot be processed in a timely and effective manner, and it costs a lot of money, material resources and time for transportation and installation. , cluttered pipelines and other problems, to achieve the effect of good market promotion value, convenient man-machine dialogue, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Structure and working process of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

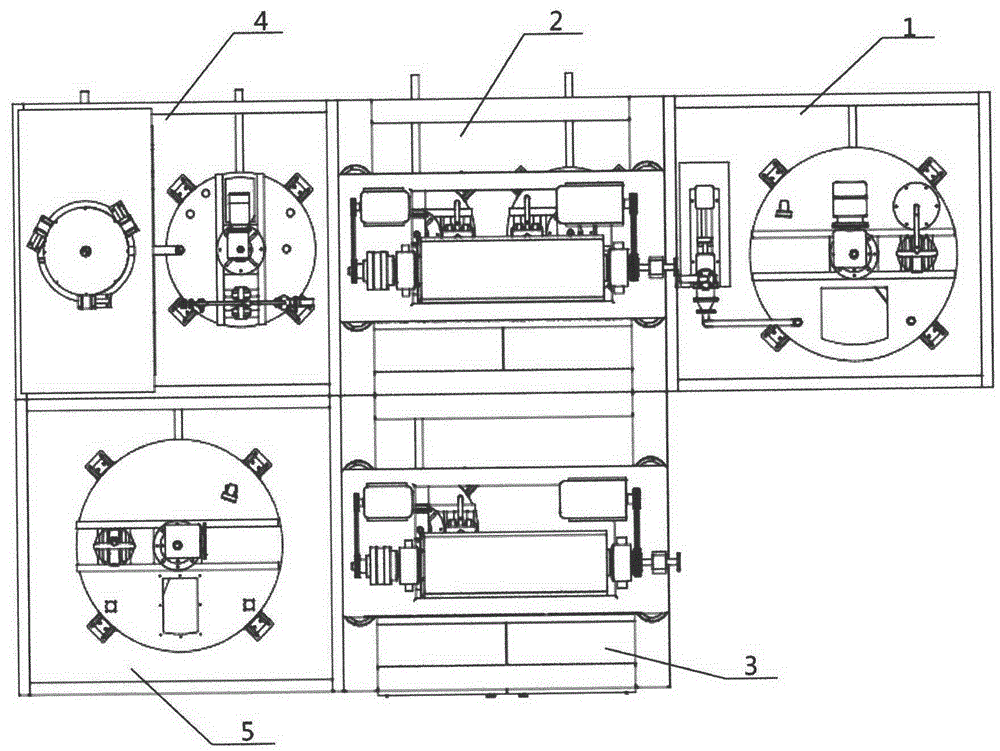

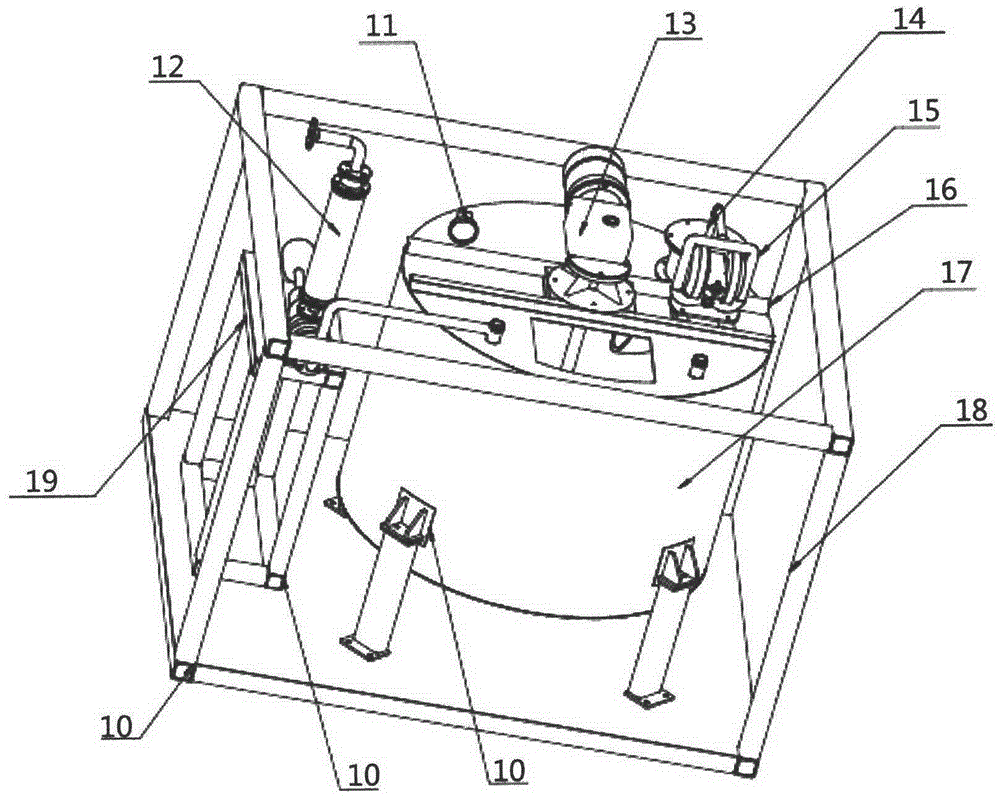

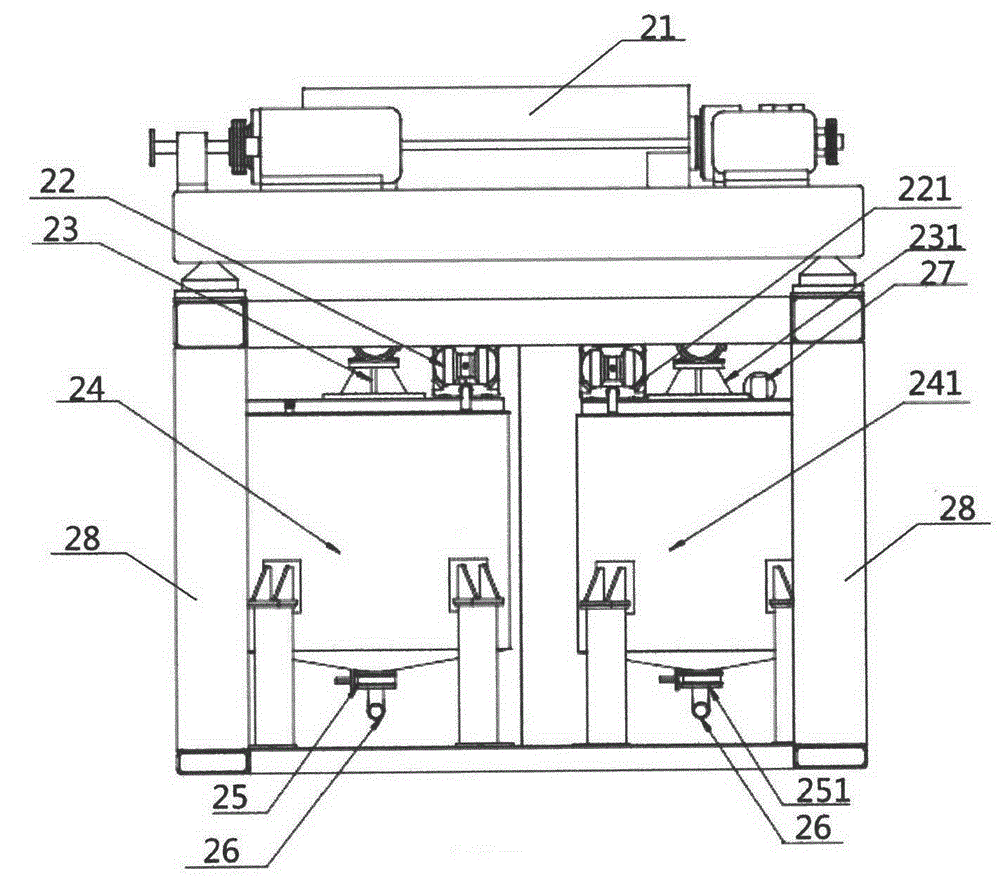

[0035] Such as Figure 1~6As shown in the figure, the modular combination crystal silicon multi-wire cutting waste mortar online recycling system is mainly composed of: collection system 1, primary separation system 2, secondary separation system 3, mixing and blending system 4, finished product system 5 and steel frame Among them, the outlet pipes of the mortar conveying pipelines of the collection system 1, primary separation system 2, secondary separation system 3, mixing and blending system 4, and finished product system 5 all adopt PVC soft interfaces and quick interfaces, and the control signal lines and power cables are uniform. Concealed aviation connectors and safety control panels are used. The entire system equipment is controlled by man-machine dialogue interface and fully automatic control. It can be assembled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com