Automatic spray printing machine

A jet printer and automatic technology, applied in printing, typewriter, sending objects, etc., can solve the problems of difficult to track processing time, difficult to track and find the quality of circuit board products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The automatic printing mechanism provided by the technical solution will be further described in detail below in conjunction with multiple drawings and embodiments.

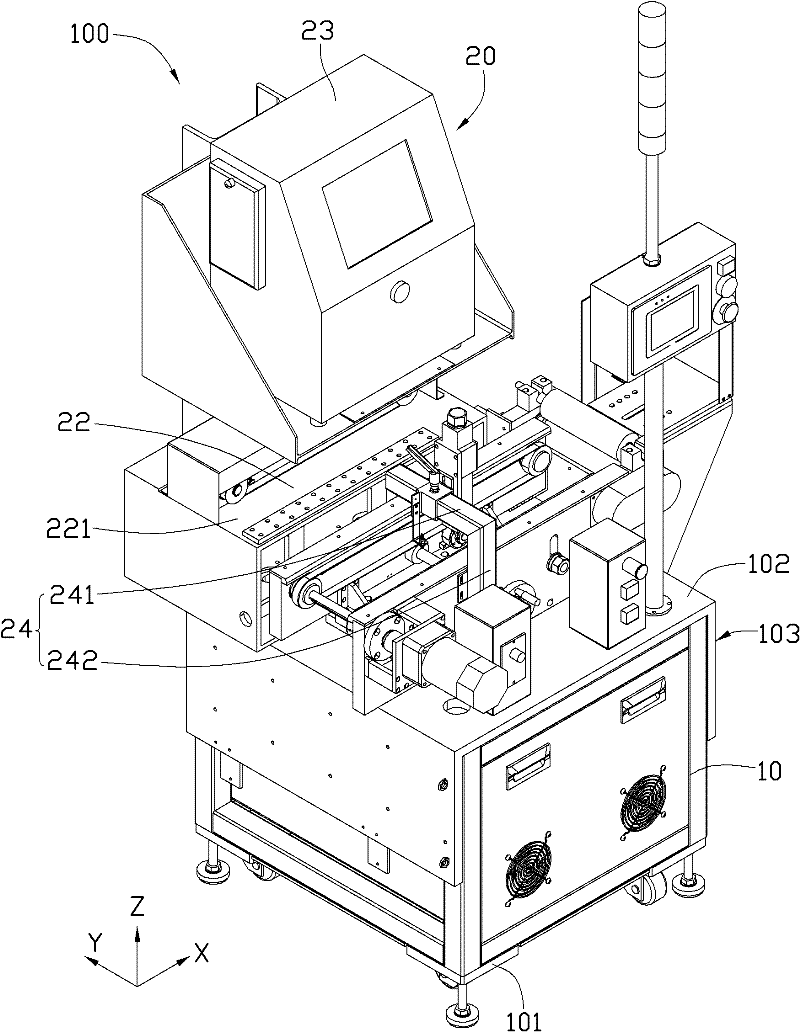

[0071] The automatic jet printing machine 100 provided by this technical solution includes a chassis 10 , a jet printing device 20 , a conveying adjustment device 30 and a receiving device 40 .

[0072] see figure 1 , the appearance of the chassis 10 is in the shape of a cuboid. Inside the cabinet 10 is a control system that controls the entire machine. In this embodiment, a carrier frame 101 is provided at the bottom of the case 10 for carrying the case 10 . Rollers are installed on the bottom of the carrier frame 101 . The case 10 has an upper surface 102 and a first side 103 vertically connected to the upper surface 102 . In this embodiment, the plane parallel to the upper surface 102 is defined as the XY plane and the direction perpendicular to the upper surface 102 is defined as the Z-axis directi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap