Hinge type aerodynamic braking device

A technology of aerodynamic braking and braking devices, applied in the direction of brakes, braking components, transportation and packaging, etc., which can solve the problems of high maintenance costs and rail wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment:

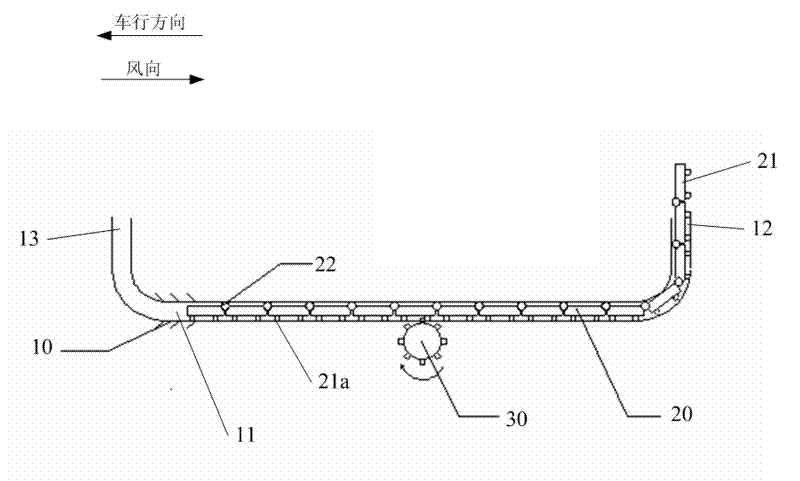

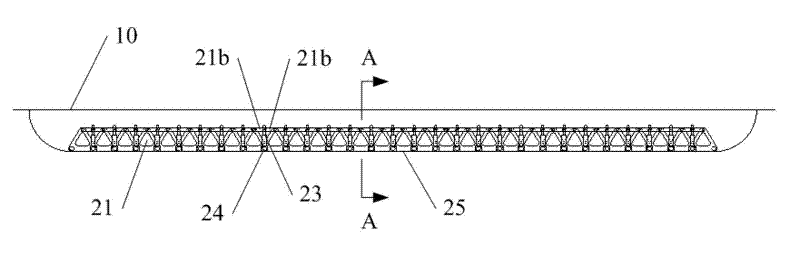

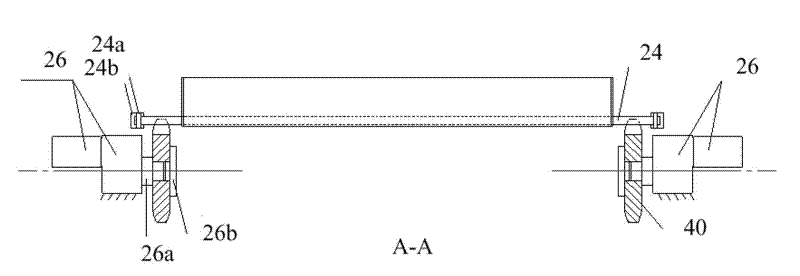

[0030] Such as figure 1 As shown, a hinged aerodynamic braking device is arranged in an accommodation space 11 on the top surface of the train 10. The braking device includes a wing body 20 and a driving device, and the wing body 20 consists of It consists of several vane units 21 arranged along the length direction of the train body, and the adjacent vane units 21 are at least connected by hinges, and the hinge position 22 is located on the side of the vane unit 21 close to the top surface of the accommodation space 11; The accommodating space 11 is arranged along the length direction of the train body, and its size is not smaller than the wing body 20, and the end of the accommodating space 11 is provided with an upward first entrance and exit 12; the driving device can drive the wing unit 21 Move, so that a part of the wing unit 21 of the wing body 20 protrudes vertically upward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com