High current semiconductor laser drive power and its control method

A technology of driving power supply and high current, which is applied to semiconductor lasers, lasers, laser parts, etc., can solve the problems of inflexible use, increased failure rate of the whole machine, limitation of the output current of the whole machine, etc., to overcome debugging difficulties Complex, prolong service life, avoid the effect of inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

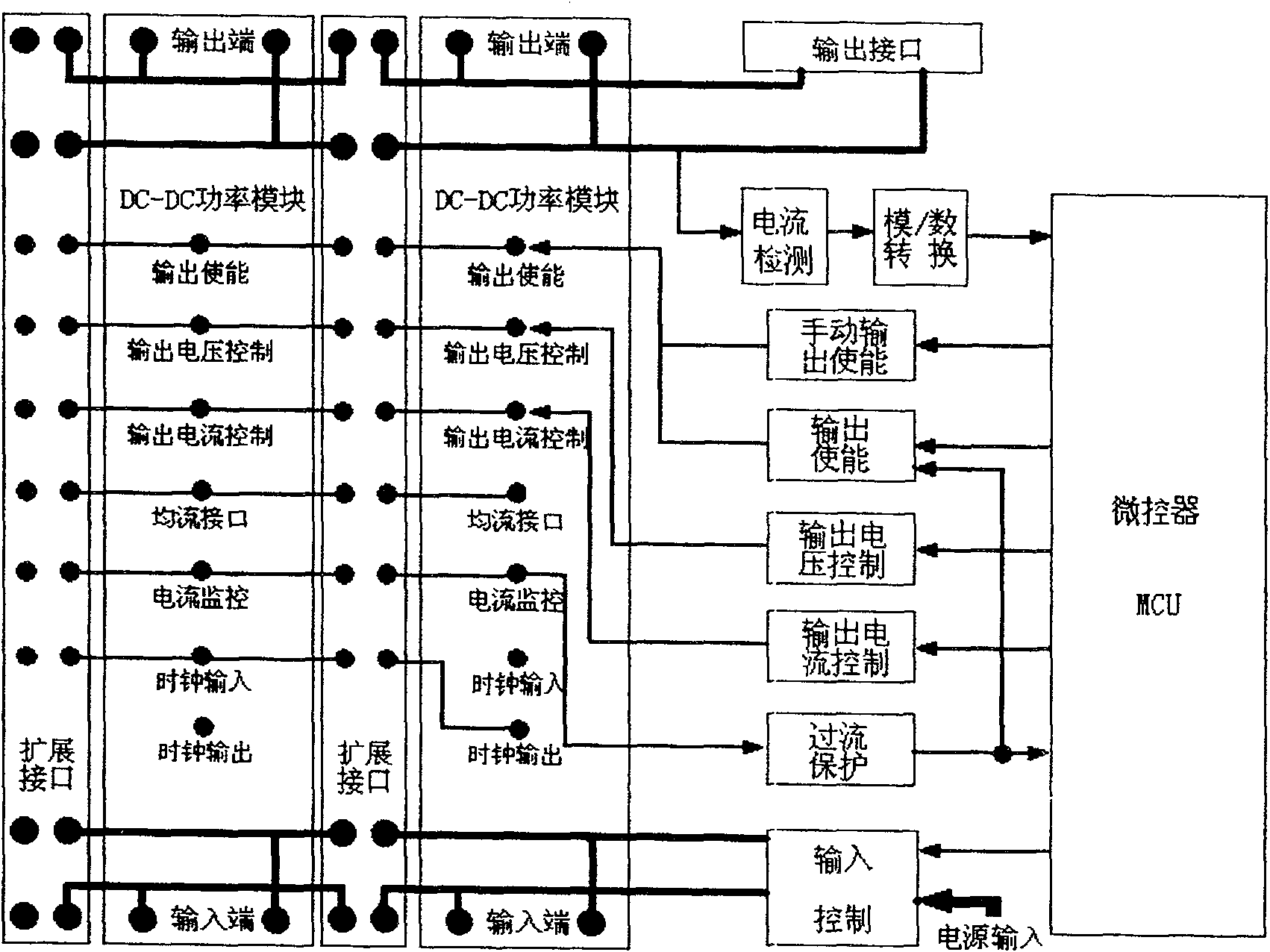

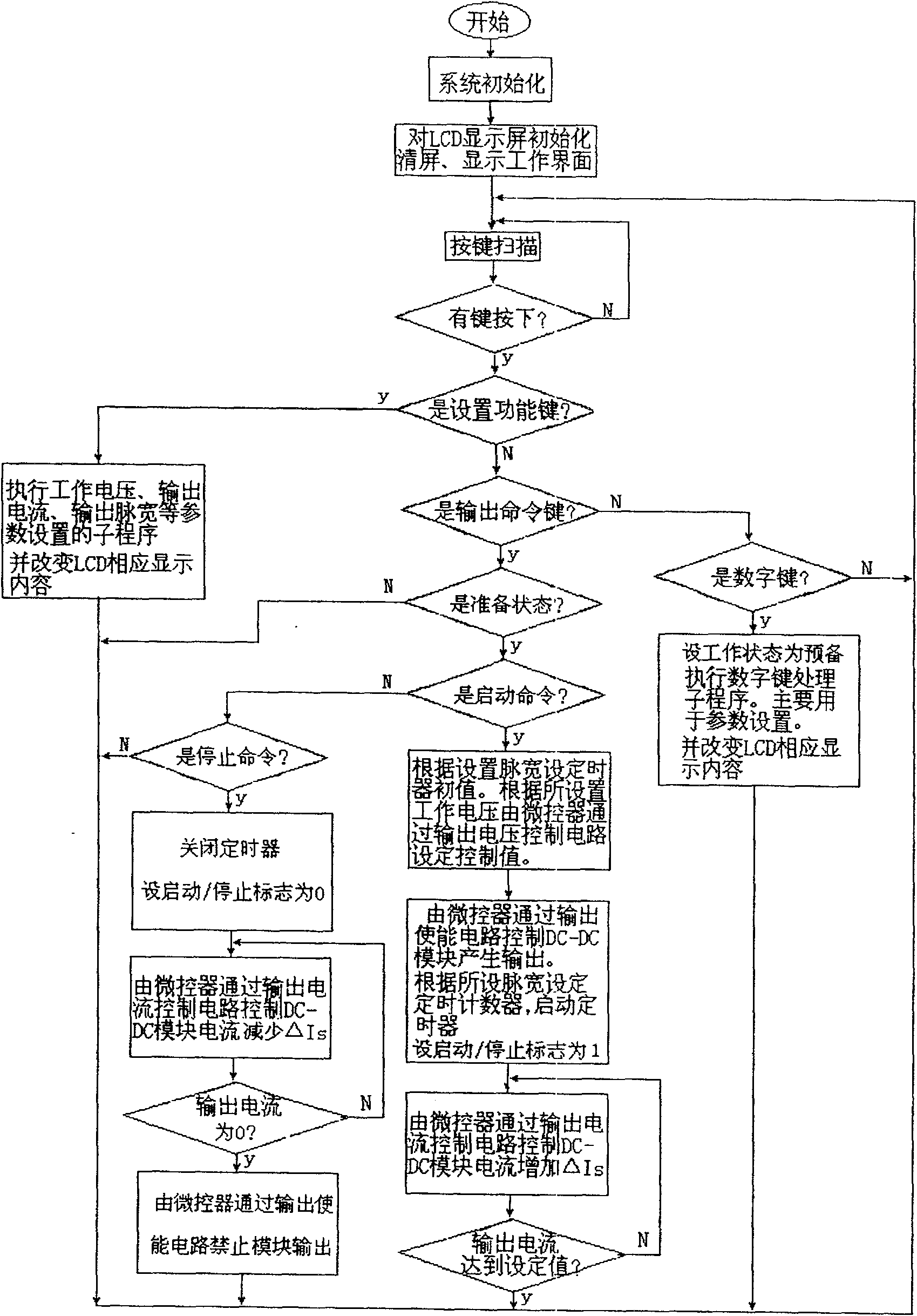

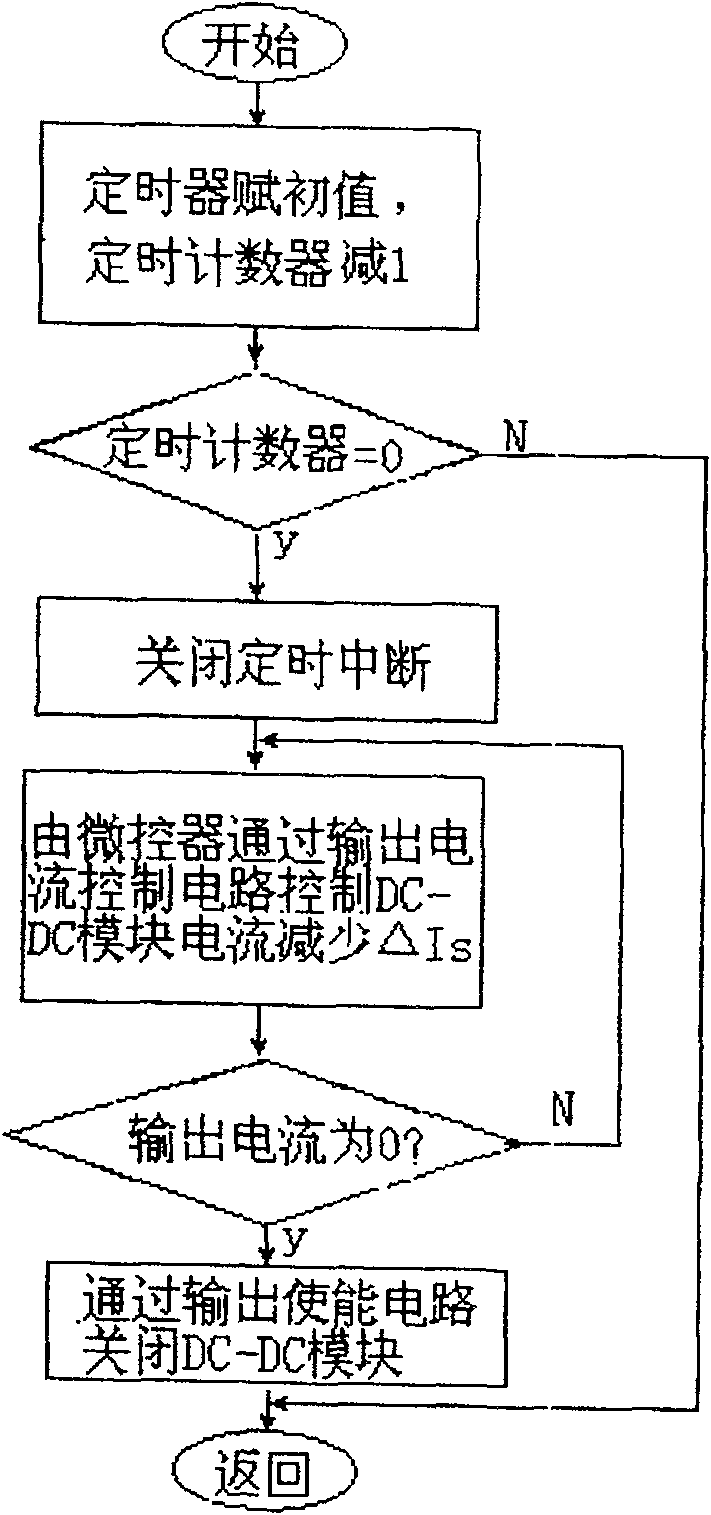

[0038] see Figure 5 , the high-current semiconductor laser drive power supply of the present invention consists of a microcontroller, an input keyboard, a liquid crystal display, a current detection circuit, an output voltage control circuit, an output current control circuit, an output enable circuit, a protection circuit, an analog-to-digital conversion circuit, a rectifier It consists of filter circuit, input control circuit, module quantity input circuit, fan control circuit, and scalable modular current output circuit composed of high-power DC-DC modules.

[0039] see figure 1 , Figure 5 , the control circuit centered on the microcontroller consists of a microcontroller, an input keyboard, a liquid crystal display, a current detection circuit, an output voltage control circuit, an output current control circuit, an output enabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com