A horizontal plastic water cellar and its assembly method

A technology of plastic water cellar and assembly method, which is applied in the direction of large-capacity bulk material storage, building types, buildings, etc., can solve the problems of easy aging of sealing rings, low utilization rate of water storage, and unreliable sealing, so as to prevent the loss of manhole covers , Improve efficiency and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

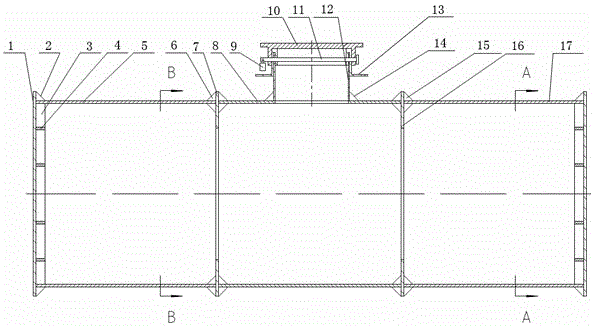

[0032] Embodiment 1: as figure 1 As shown, a horizontal plastic water cellar, specifically a horizontal plastic water cellar with flange ribs, includes an end cover 1, reinforcing ribs I2, radial ribs 3, annular ribs 4, cellar body I5, reinforcing ribs II6, method Blue bar Ⅰ7, cellar body Ⅱ8, lock 9, well cover 10, lock bolt 11, well shaft 12, well cover base 13, reinforcing rib Ⅲ14, reinforcing rib Ⅳ15, flange rib Ⅱ16, cellar body Ⅲ17, diversion hole.

[0033] The ring rib 4 is welded with the end cover 1; the pit body I5 is welded with the end cover 1; the radial rib 3 is welded with the end cover 1, the annular rib 4, and the pit body I5; the reinforcement rib I2 is welded with the end cover 1 and the pit body I5; the flange Rib Ⅰ7 is welded to pit body Ⅰ5; pit body Ⅱ8 is welded to flange rib Ⅰ7; reinforcing rib Ⅱ6 is welded to pit body Ⅰ5, flange rib Ⅰ7, and pit body Ⅱ8; shaft 12 is welded to pit body Ⅱ8; reinforcing rib Ⅲ14 is welded to pit body Ⅱ8, wellbore 12 welded; f...

Embodiment 2

[0035] A horizontal plastic water cellar, including end cover 1, reinforcing rib I2, radial rib 3, circular rib 4, cellar body I5, reinforcing rib II6, flange rib I7, cellar body II8, lock 9, well cover 10, and lock bolt 11. Well shaft 12, well cover base 13, reinforcing rib Ⅲ14, reinforcing rib Ⅳ15, flange rib Ⅱ16, cellar body Ⅲ17, diversion hole; annular rib 4 is welded to end cover 1; cellar body Ⅰ5 is welded to end cover 1; radial ribs 3 Weld with end cover 1, ring rib 4, pit body Ⅰ5; reinforcement rib Ⅰ2 weld with end cover 1, pit body Ⅰ5; flange rib Ⅰ7 weld with pit body Ⅰ5; pit body Ⅱ8 weld with flange rib Ⅰ7; Ⅱ6 is welded with pit body Ⅰ5, flange rib Ⅰ7, and pit body Ⅱ8; shaft 12 is welded with pit body Ⅱ8; reinforcing rib Ⅲ14 is welded with pit body Ⅱ8 and well shaft 12; flange rib Ⅱ16 is welded with pit body Ⅱ8; pit body Ⅲ17 is welded with Flange rib II16 is welded; reinforcement rib IV15 is welded to cellar body II8, flange rib II16, cellar body III17; well cover ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com