Automatic connecting/disconnecting device for braking air ducts of railroad vehicles

A technology for railway vehicles and connectors, applied in railway couplings, railway car body components, transportation and packaging, etc., can solve problems such as low efficiency, threat to operators' personal safety, low degree of automation, etc., and achieve easy maintenance, The effect of shortening the operating speed and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

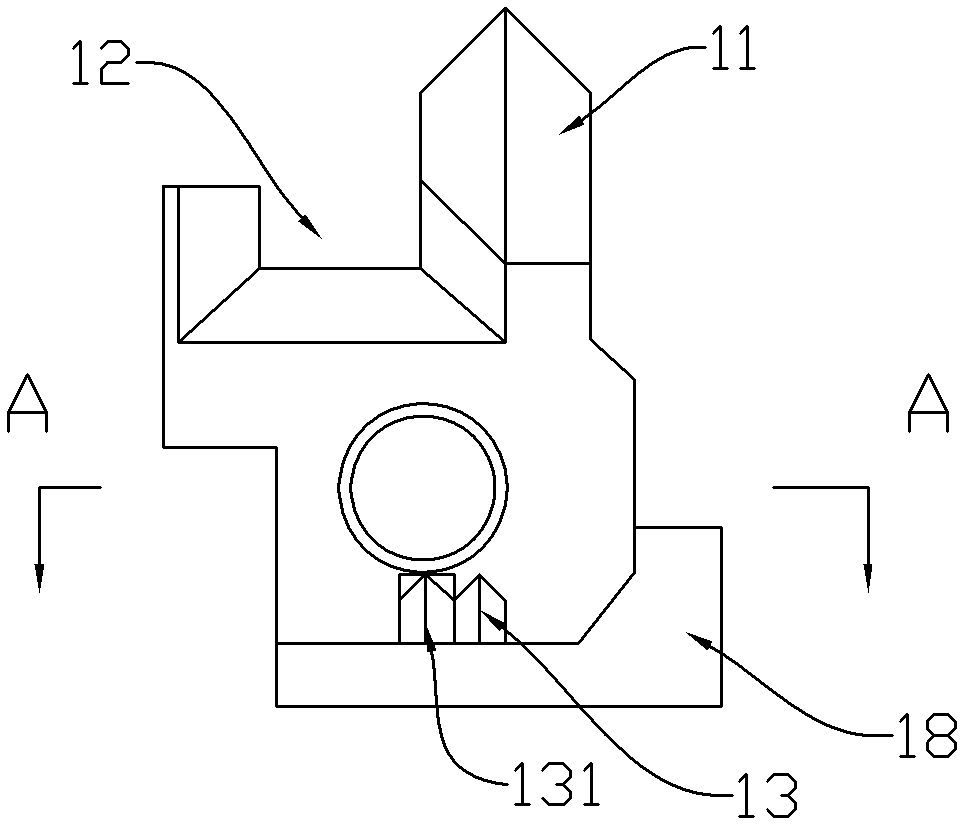

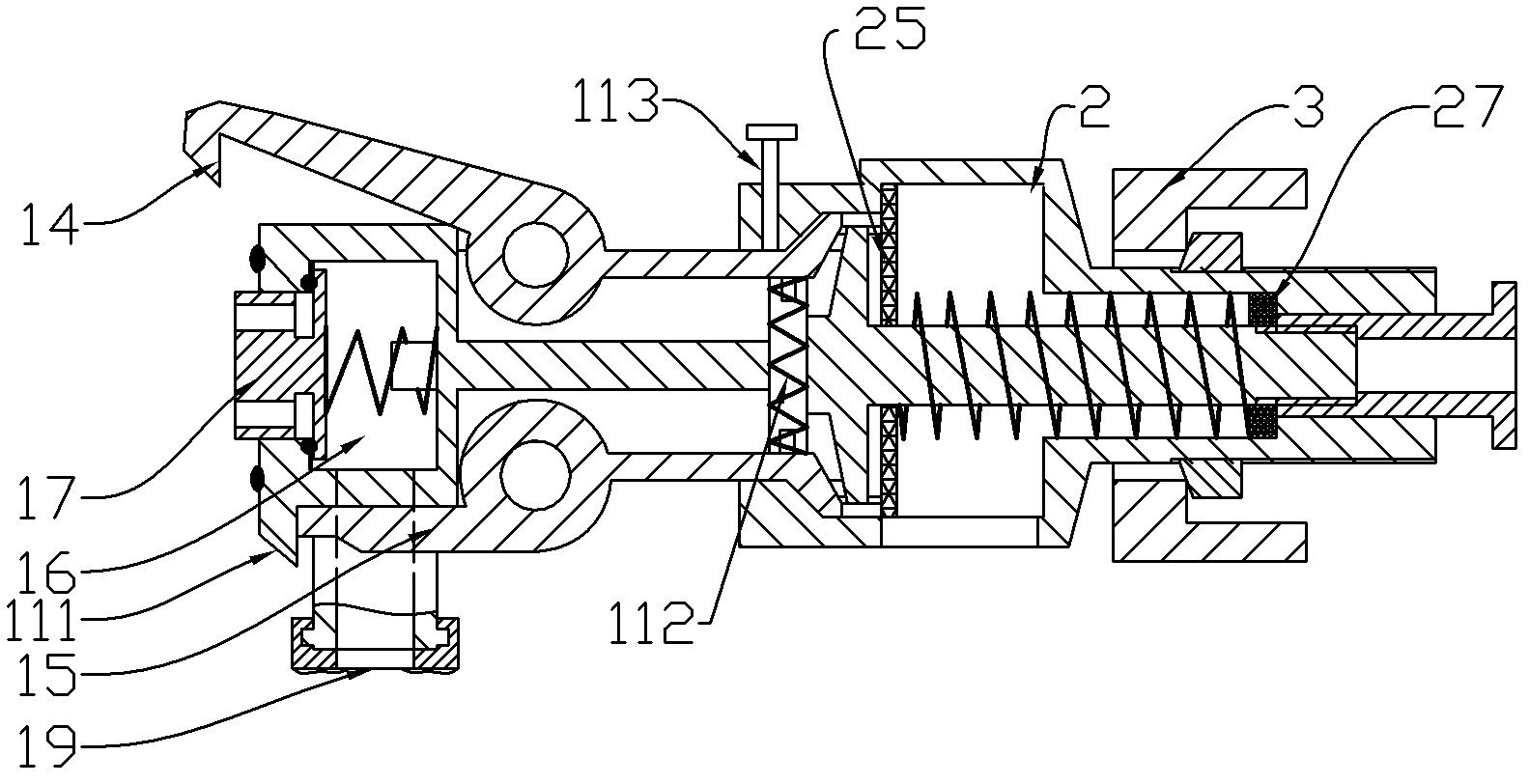

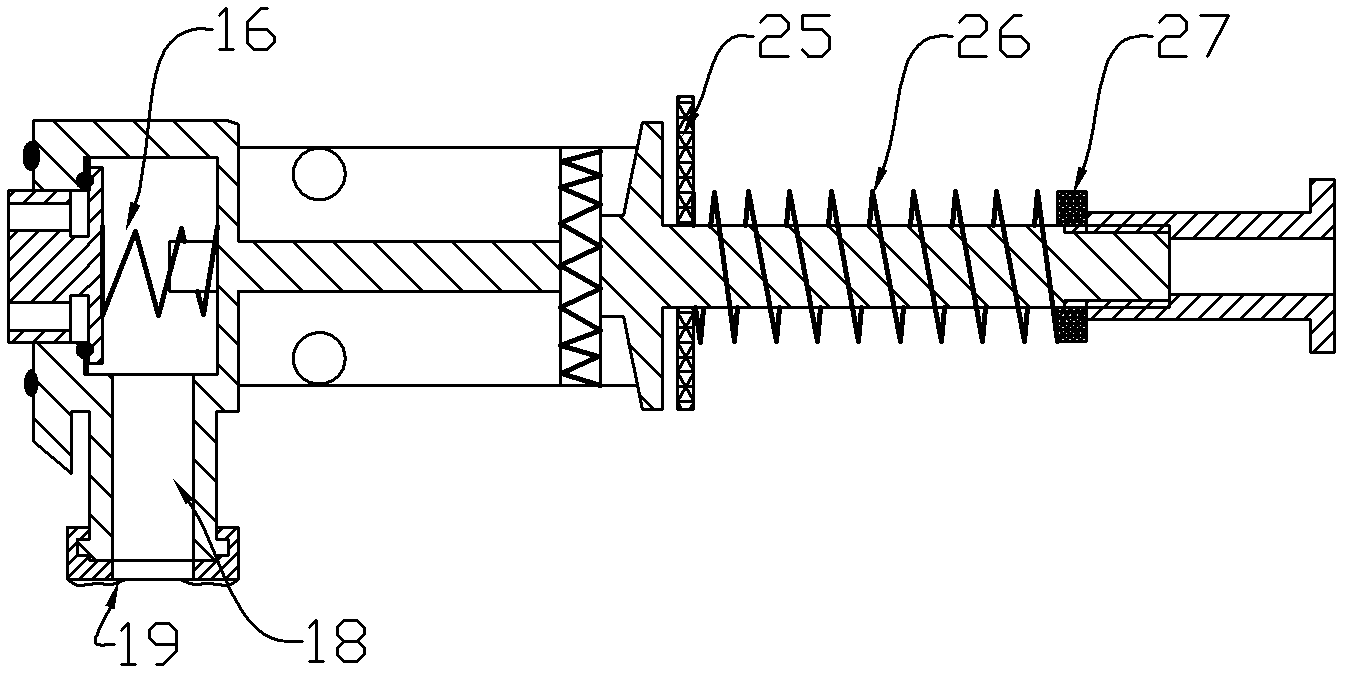

[0028] Such as Figure 1~6 As shown, this automatic brake air pipe coupler for railway vehicles includes a coupler main body 1 , a box cover 2 and a mounting seat 3 for fixing.

[0029] The cross-section of the front half of the main body 1 of the joint is square, and the cross-section of the second half is circular; There are positioning protrusions 13 and positioning grooves 131, and the two sides and the upper and lower sides of the adjustment protrusions are all curved surfaces. After the main bodies of the two connectors adjacent to each other are close to each other, under the action of external force, the two connectors are firstly adjusted through the left and right adjustment protrusions, and then the precise positioning is realized through the positioning protrusions. They are gradually closed in the way of insertion, and they together form an adjustment mechanism, which is a guided insertion structure.

[0030] On both sides of the front part of the receiver main ...

Embodiment 2

[0042] Such as Figure 10 ~ Figure 12 as shown,

[0043] The difference from Embodiment 1 lies in the difference in the valve assembly. In this embodiment, the valve assembly is an angle valve, also called a rotary valve, which controls the opening and closing of the valve through the rotation of the valve core. This knuckle valve has a similar structure to the existing knuckle plug. The knuckle valve includes a spherical or columnar valve core 41 installed in the cavity. In this state, similar to the structure of the existing ball valve, the valve core 41 is integrated with a valve handle through a rotating shaft. In order to cooperate with the function of automatic connection, the key point is to improve the shape of the valve handle 42. The valve handle 42 is semi-circular and located on the lower side of the valve core, and is provided with and opposite to the valve on the front surface of the main body of the connector. The push-pull rod matched with the handle, the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com