Synchronous structure of crawler-type counterweight trolley and crane comprising same

A counterweight trolley and crawler technology, applied in cranes and other directions, can solve the problems of extremely high mechanical performance requirements, high price, large loss, etc., and achieve the effect of ensuring synchronous control accuracy, enhancing stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following combined with the attachment and the specific embodiments further explained the present invention, but it is not limited to the present invention.

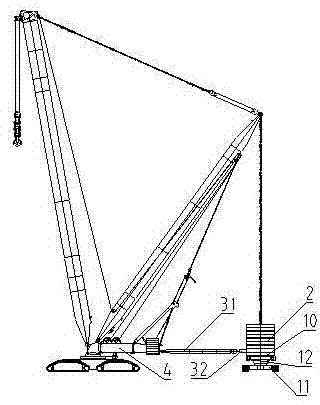

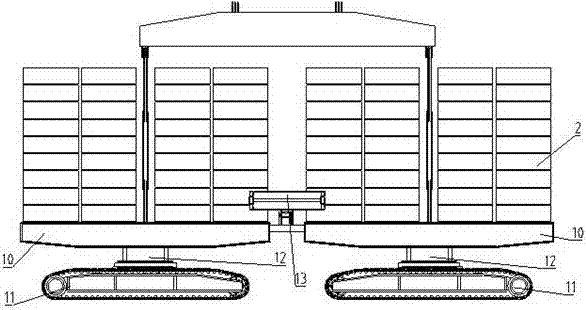

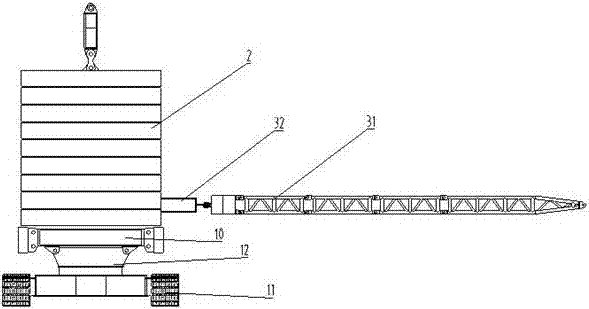

[0028] like figure 1 As well as figure 2 As well as image 3 As well as Figure 4 and Figure 5 It shows that the present invention has a curivocated heavy car synchronization structure, including the bearing device and multiple heavy weights 2 for carrying weight. Among themFormed, each car body 10 includes a crawler walking mechanism 11, a crawler walking mechanism 11 to connect to the lower part of the car body 10 through the turn support component 12.The central part is connected to the rear of the host 4 through one connection component, and the weight 2 is placed on the two car body 10 according to the preset ratio.

[0029] The principle of the present invention is that the tracked walking mechanism below the two car body 11 can turn around through the turn support component 12, so that the structure provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com