A high-efficiency aerated grit chamber with slag scraping function

An aeration grit chamber technology, applied in the field of grit chambers, can solve problems such as roughness, damage, and huge kinetic energy consumption, meet the requirements of reducing mechanical properties, accelerate the mixing of chemicals, and improve the aeration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

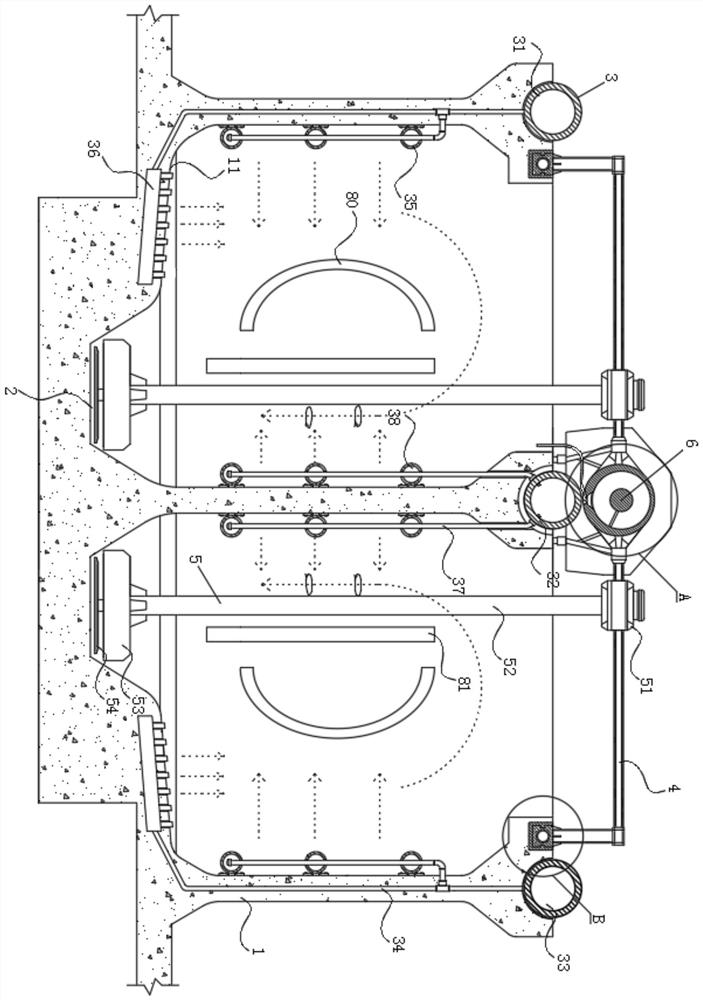

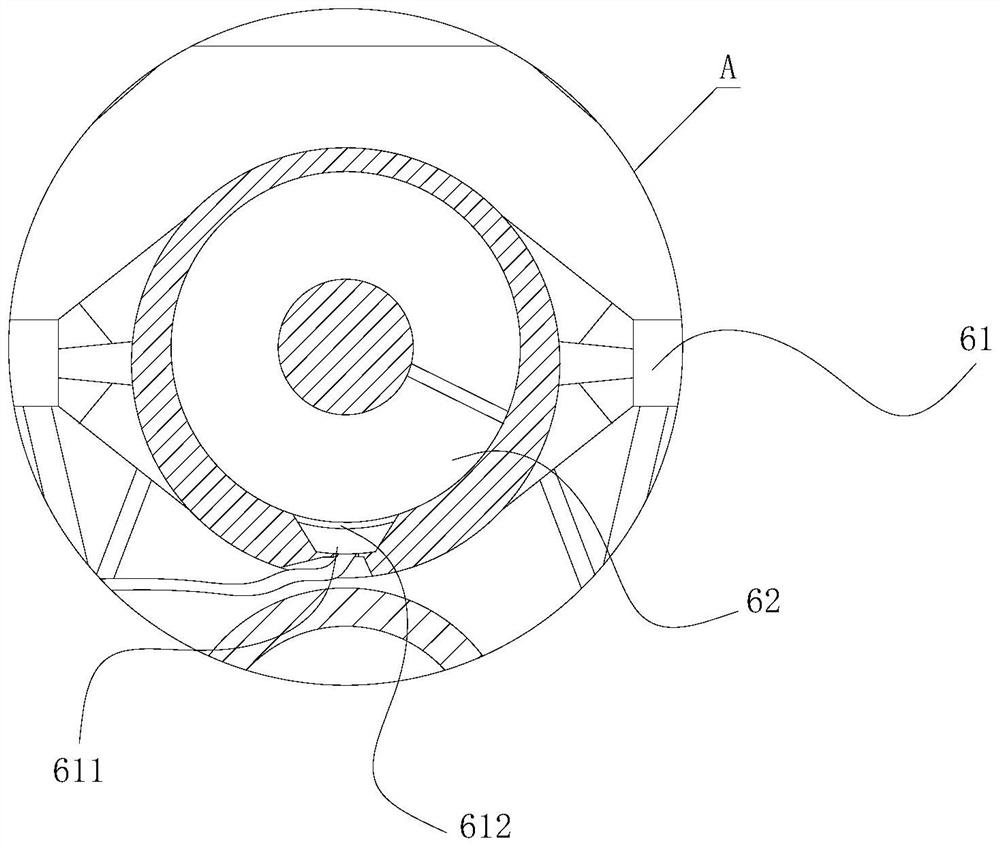

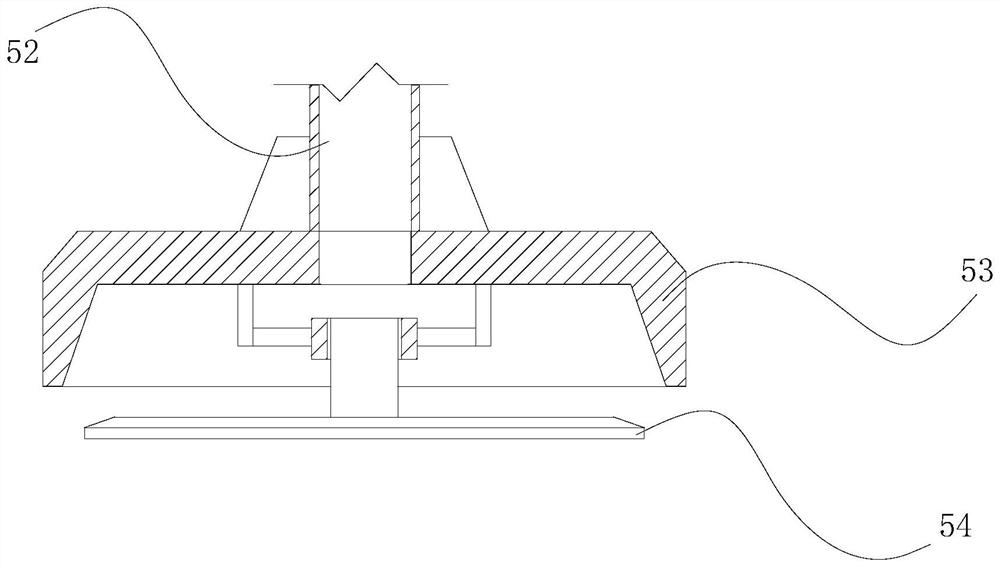

[0031] like Figure 1-5 As shown, a high-efficiency aerated grit chamber with slag scraping function comprises a mirror-built grit chamber body 1, and the bottom of the grit chamber body 1 is preset with a sand accumulation channel 2 distributed close to one of the inner walls, The aeration pipeline system 3 is installed on the opposite sides of the grit chamber body 1 and the bottom of the tank. The aeration pipeline system 3 is used to make the liquid in the two grit chamber bodies 1 move away from one side of the pool wall to the opposite side. The adjacent side of the pool wall flows, so that the sediment is deposited into the sand accumulation channel 2;

[0032] The tops of the two grit chamber bodies 1 are installed with a gantry moving frame 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com