Degradable noctilucent zipper

A zipper and long-lasting luminous powder technology, applied in the zipper field, can solve the problems of poor degradability of POM plastics, poor transparency of POM plastics, hindering the development of the zipper industry, etc., and achieve the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

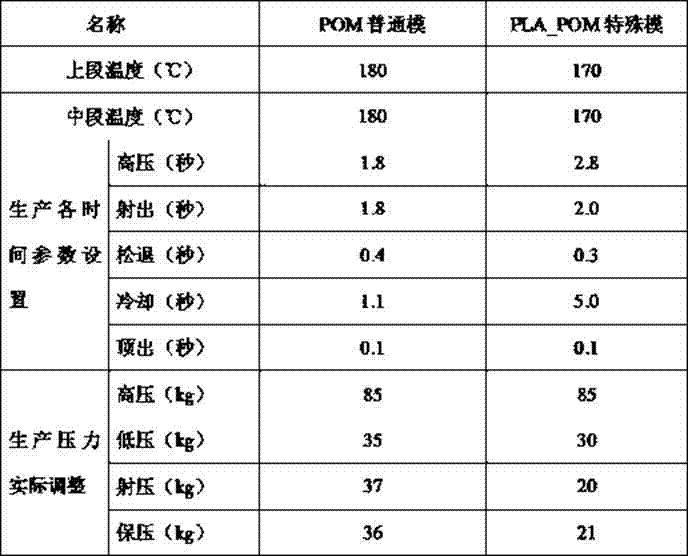

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: In this embodiment, 65 parts of PLA, 30 parts of POM, 5.0 parts of long-lasting luminous powder, and 0.1 part of Red A transparent plastic pigment are added according to the weight ratio, and the produced zipper has better mold release and better zipper smoothness , and has a very strong luminous effect.

Embodiment 2

[0017] Embodiment 2: In this embodiment, 65 parts of PLA, 30 parts of POM, 4.0 parts of long-lasting luminous powder, and 0.1 part of Red A transparent plastic pigment are added according to the weight ratio, and the produced zipper has better demoulding and better zipper smoothness , and has a strong luminous effect.

Embodiment 3

[0018] Embodiment 3: In this embodiment, 65 parts of PLA, 30 parts of POM, 3.0 parts of long-lasting luminous powder, and 0.1 part of Red A transparent plastic pigment are added according to the weight ratio, and the produced zipper has better mold release and better zipper smoothness , and has a strong luminous effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com