Preparation method of high-strength wear-resistant noctilucent zipper

A high-strength zipper technology, applied in applications, clothing, sliding fastener components, etc., can solve the problems of affecting the service life of zippers, low strength of zipper chains, and low strength of resin zippers, so as to improve travel safety and increase luminous effect , Improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

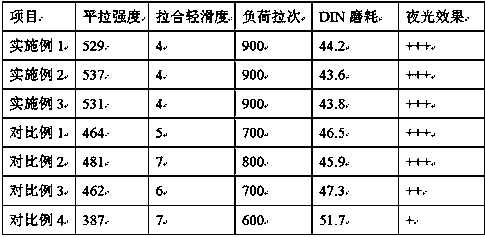

Examples

Embodiment 1

[0023] A preparation method of a high-strength wear-resistant luminous zipper, comprising the following steps:

[0024] (1) Preparation of modified polyamide: put the polyamide in the reaction kettle, heat until it is completely melted, keep it warm for 15 minutes, add diphenylsilanediol into the reaction kettle, the addition amount is 6.1% of the weight of the polyamide, keep stirring 10min, then add tetraethyl orthocarbonate, the addition amount is 3.2% of the polyamide weight, heat preservation and stirring for 20min, then add calcium titanate into the reaction kettle, the particle size is 60~70nm, the addition amount is 1.7% of the polyamide weight , heat preservation and stirring for 40 minutes, can improve the strength and wear resistance of polyamide, enhance the wear resistance of zipper, and obtain modified polyamide;

[0025] (2) Preparation of modified polyethylene wax: fully melt the polyethylene wax, heat and stir for 15 minutes, add amino silicone oil with 2% wei...

Embodiment 2

[0032] A preparation method of a high-strength wear-resistant luminous zipper, comprising the following steps:

[0033] (1) Preparation of modified polyamide: put the polyamide in the reaction kettle, heat until it is completely melted, keep it warm for 18 minutes, add diphenylsilanediol into the reaction kettle, the addition amount is 6.2% of the weight of the polyamide, keep stirring 13 minutes, then add tetraethyl orthocarbonate, the addition amount is 3.3% of the polyamide weight, heat preservation and stirring for 23 minutes, then add calcium titanate into the reaction kettle, the particle size is 60~70nm, the addition amount is 1.8% of the polyamide weight , heat preservation and stirring for 45 minutes, can improve the strength and wear resistance of polyamide, enhance the wear resistance of zipper, and obtain modified polyamide;

[0034](2) Preparation of modified polyethylene wax: fully melt the polyethylene wax, heat and stir for 18 minutes, add amino silicone oil wi...

Embodiment 3

[0041] A preparation method of a high-strength wear-resistant luminous zipper, comprising the following steps:

[0042] (1) Preparation of modified polyamide: put the polyamide in the reaction kettle, heat until it is completely melted, keep it warm for 20 minutes, add diphenylsilanediol into the reaction kettle, the addition amount is 6.3% of the weight of the polyamide, keep stirring 15 minutes, then add tetraethyl orthocarbonate, the addition amount is 3.4% of the polyamide weight, heat preservation and stirring for 25 minutes, then add calcium titanate into the reaction kettle, the particle size is 60~70nm, the addition amount is 1.9% of the polyamide weight , heat preservation and stirring for 50 minutes, can improve the strength and wear resistance of polyamide, enhance the wear resistance of zipper, and obtain modified polyamide;

[0043] (2) Preparation of modified polyethylene wax: fully melt the polyethylene wax, heat and stir for 20 minutes, add amino silicone oil w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com