Far infrared powder for energy-saving coating and preparation method for far infrared powder

A far-infrared powder, energy-saving technology, applied in coatings and other directions, can solve the problems of unstable quality, weak effect, complicated use, etc., and achieve the effect of simple preparation process, wide range of use, and improved energy-saving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

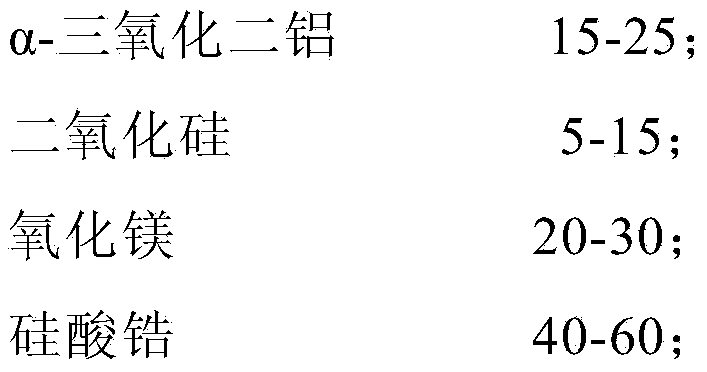

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of far-infrared powder for energy-saving coatings, the method comprising the following steps:

[0031] (1) Preparation of α-alumina and magnesium oxide

[0032] Pulverize the α-aluminum oxide and magnesium oxide raw materials with a flat jet mill to a particle size of 2 microns to obtain depolymerized α-aluminum oxide and magnesium oxide;

[0033] (2) Preparation of silica

[0034] Pulverize the silicon dioxide raw material with an original particle size of 0.5 microns to a particle size of 0.2 microns with a flat jet mill to obtain depolymerized silica;

[0035] (3) Preparation of zirconium silicate

[0036] The zirconium silicate powder with an average particle size of 10 microns is pulverized by a stirring ball mill or a sand mill to an average particle size of 2 microns, dried and then pulverized by a flat jet mill to obtain depolymerized zirconium silicate;

[0037] (4) Preparation of nanometer far-infrared materials

[0038] Prepare materi...

Embodiment 2

[0042] A preparation method of far-infrared powder for energy-saving coatings. The method comprises the following steps:

[0043] (1) Preparation of α-alumina and magnesium oxide

[0044] Pulverize the α-aluminum oxide and magnesium oxide raw materials with a flat jet mill to a particle size of 3 microns to obtain depolymerized α-aluminum oxide and magnesium oxide;

[0045] (2) Preparation of silica

[0046] Pulverize the silicon dioxide raw material with an original particle size of 0.5 microns to a particle size of 0.4 microns with a flat jet mill to obtain depolymerized silica;

[0047] (3) Preparation of zirconium silicate

[0048] The zirconium silicate powder with an average particle size of 10 microns is pulverized by a stirring ball mill or a sand mill to an average particle size of 2 microns, dried and then pulverized by a flat jet mill to obtain depolymerized zirconium silicate;

[0049] (4) Preparation of nanometer far-infrared materials

[0050] Prepare materia...

Embodiment 3

[0054] A preparation method of far-infrared powder for energy-saving coatings, the method comprising the following steps:

[0055] (1) Preparation of α-alumina and magnesium oxide

[0056] Pulverize the α-aluminum oxide and magnesium oxide raw materials with a flat jet mill to a particle size of 3 microns to obtain depolymerized α-aluminum oxide and magnesium oxide;

[0057] (2) Preparation of silica

[0058] Pulverize the silicon dioxide raw material with an original particle size of 0.5 micron to a particle size of 0.3 micron with a flat jet mill to obtain depolymerized silica;

[0059] (3) Preparation of zirconium silicate

[0060] The zirconium silicate powder with an average particle size of 10 microns is pulverized by a stirring ball mill or a sand mill to an average particle size of 2 microns, dried and then pulverized by a flat jet mill to obtain depolymerized zirconium silicate;

[0061] (4) Preparation of nanometer far-infrared materials

[0062] Prepare material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com