Back-anchored uplift pile with flexible pile top

A flexible pile and top-resistance technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of high price of fiber reinforcement and poor economic efficiency, so as to improve the pull-out bearing capacity, control the floating displacement, and reduce the pile load. The effect of body muscle ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

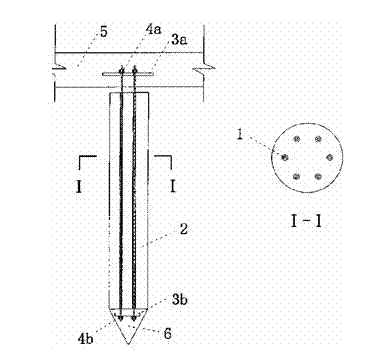

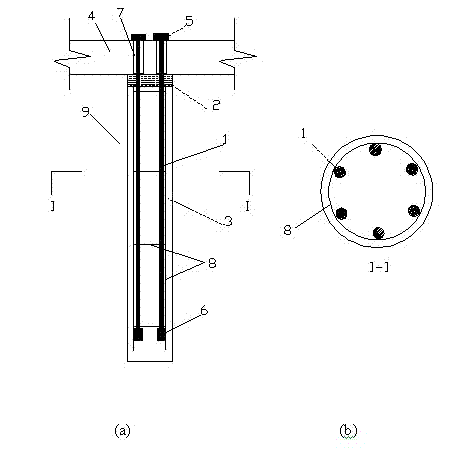

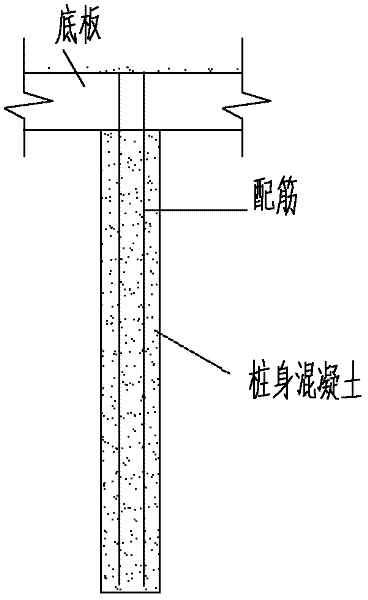

[0045] The post-anchored flexible pile top uplift (floating) pile of the present invention includes: a concrete pile body 3, a compressible flexible waterproof cushion 2 is used to fill the space between the top of the pile and the foundation beam slab 4, and the unbonded steel strand 1 The lower part is anchored at the bottom of the pile with the pile bottom anchorage 6, the unbonded steel strand 1 passes through the concrete pile body 3, the flexible connection cushion layer 2 at the top of the pile, and passes through the foundation beam plate 4 through the casing 7, and the The ends of the unbonded steel strands are not anchored during the construction of the underground structure or are only initially anchored without prestress, and can slide freely up and down in the casing 7 . After a certain amount of compression and settlement of the foundation soil occurs, tension is carried out on the part of the unbonded steel strand 1 passing through the foundation beam slab 4, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com