Controllable mechanism type loader with high bearing capacity

A high-load-capacity, mechanism-based technology, applied to mechanically driven excavators/dredgers, etc., can solve problems affecting the overall performance of loaders, poor mechanical properties of mechanisms, and low load-carrying capacity, so as to achieve broad market development potential, Improve mechanical properties and reduce self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below with reference to the accompanying drawings.

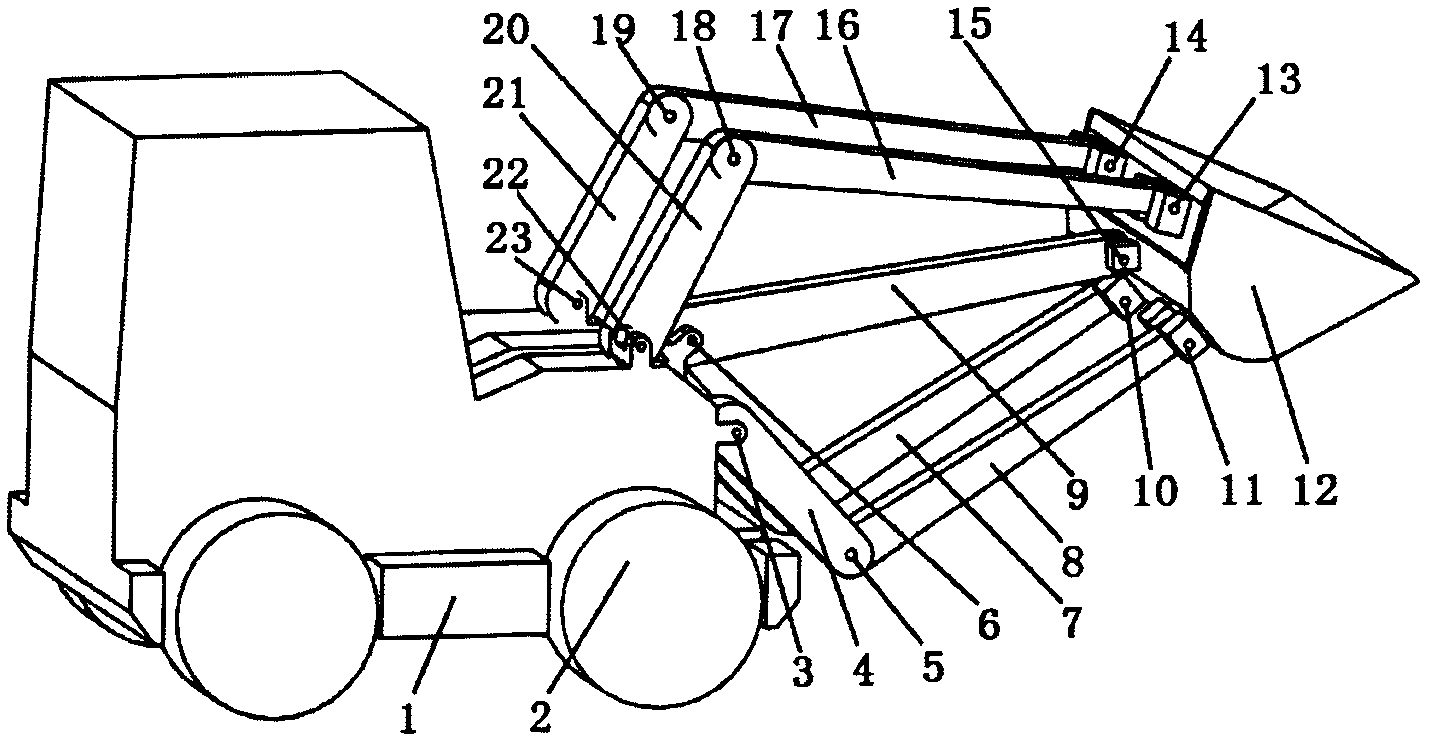

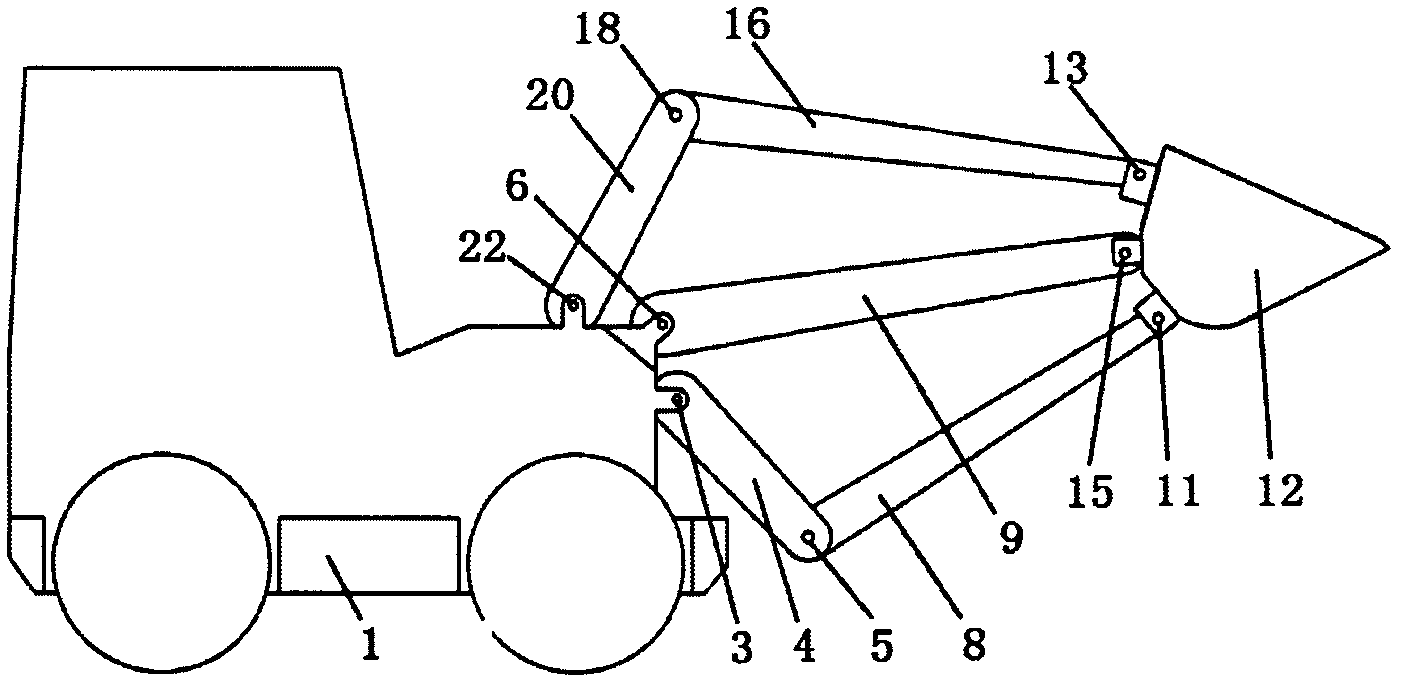

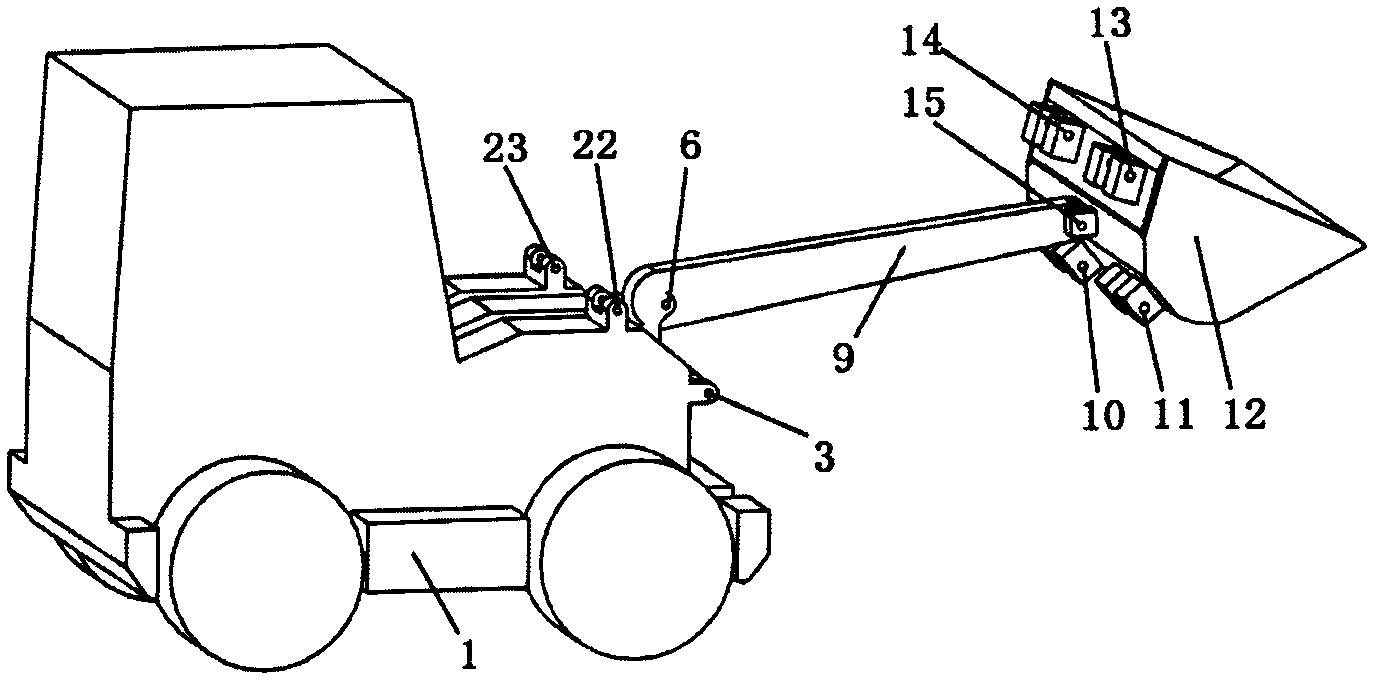

[0026] control figure 1 , figure 2 , a controllable mechanism loader with high load capacity is composed of a traveling device 2, a frame 1, a boom 9, an upper branch chain, a lower branch chain, and a bucket 12.

[0027] control figure 1 , figure 2 , image 3 , Figure 7 , the frame 1 is installed on the running gear 2, the boom 9 is connected to the frame 1 through the thirteenth hinged hole 6, and the other end of the boom 9 is connected to the bucket 12 through the fourteenth hinged hole 15.

[0028] control figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , the upper branch chain is composed of the third active rod 20, the fourth active rod 21, the first connecting rod 16, and the second connecting rod 17, and the third active rod 20 is connected with the frame 1 through the seventh reaming hole 22 , the other end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com