Hydraulic control system for scooptram

A technology of hydraulic control system and scraper, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems that the scraper cannot start and turn quickly at the same time, and uses few components, and achieves a simple structure and uses components. Fewer, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

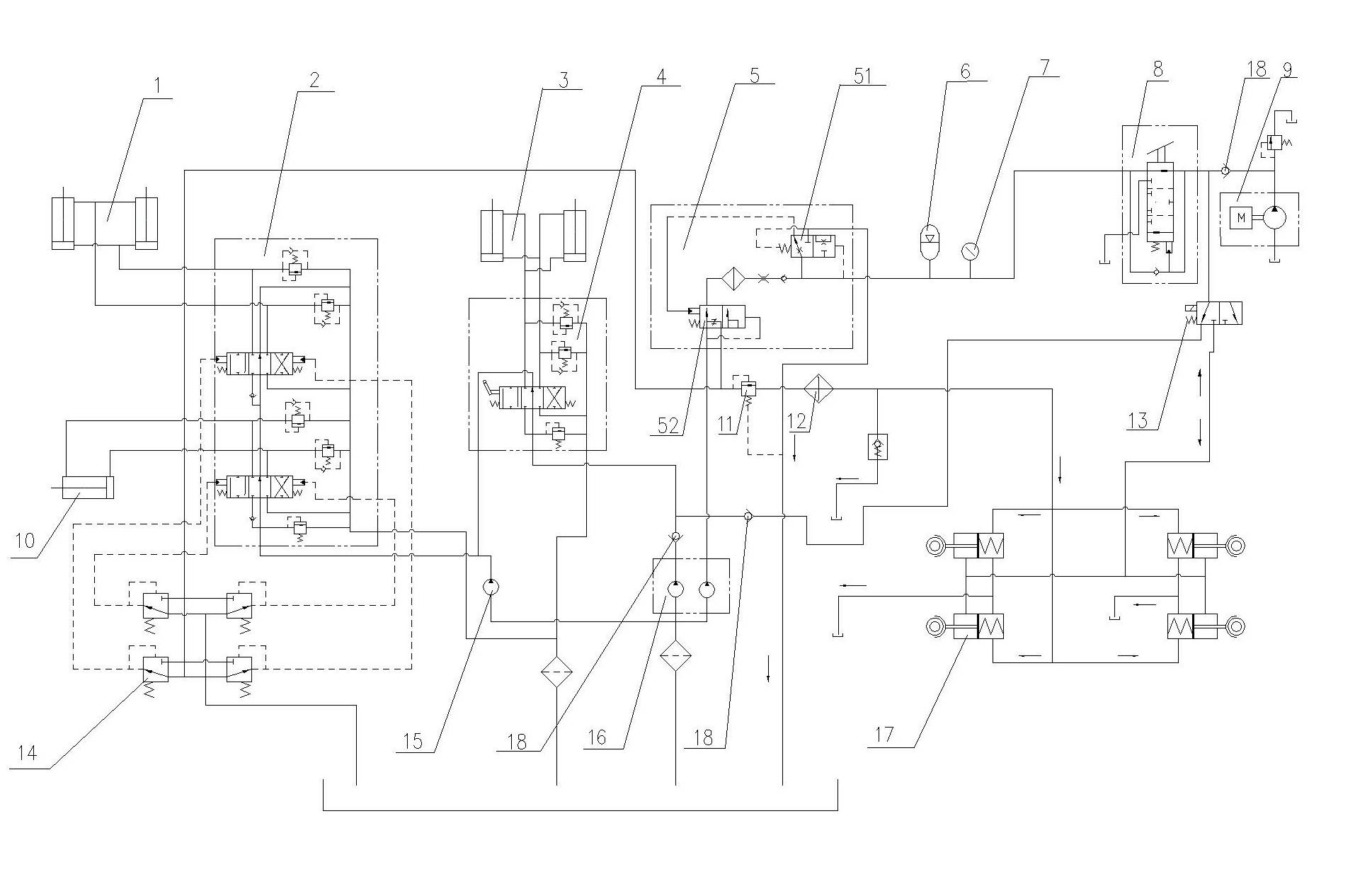

[0012] Embodiment 1, see figure 1 :

[0013] From figure 1 It can be seen that the right pump of the dual gear pump 16 is used for the oil supply of the brake circuit, and the left pump is used for the oil supply of the steering circuit. Valve 5, foot brake valve 8, electromagnetic reversing valve 13, brake 17, double gear pump 16, the right pump is directly connected to the input end of filling valve 5, the backup oil supply branch and the input end of electromagnetic reversing valve 13 Both are connected to the output end of the foot brake valve 8, one of the two output ports of the electromagnetic reversing valve 13 is connected to the brake 17, and the other is connected to the input end of the steering control valve 4 through the reverse check valve 18. When the system works normally, the electric hydraulic pump 9 does not start, which will not interfere with the normal work of the hydraulic system. The left pump of the dual gear pump 16 supplies oil to the steeri...

Embodiment approach 2

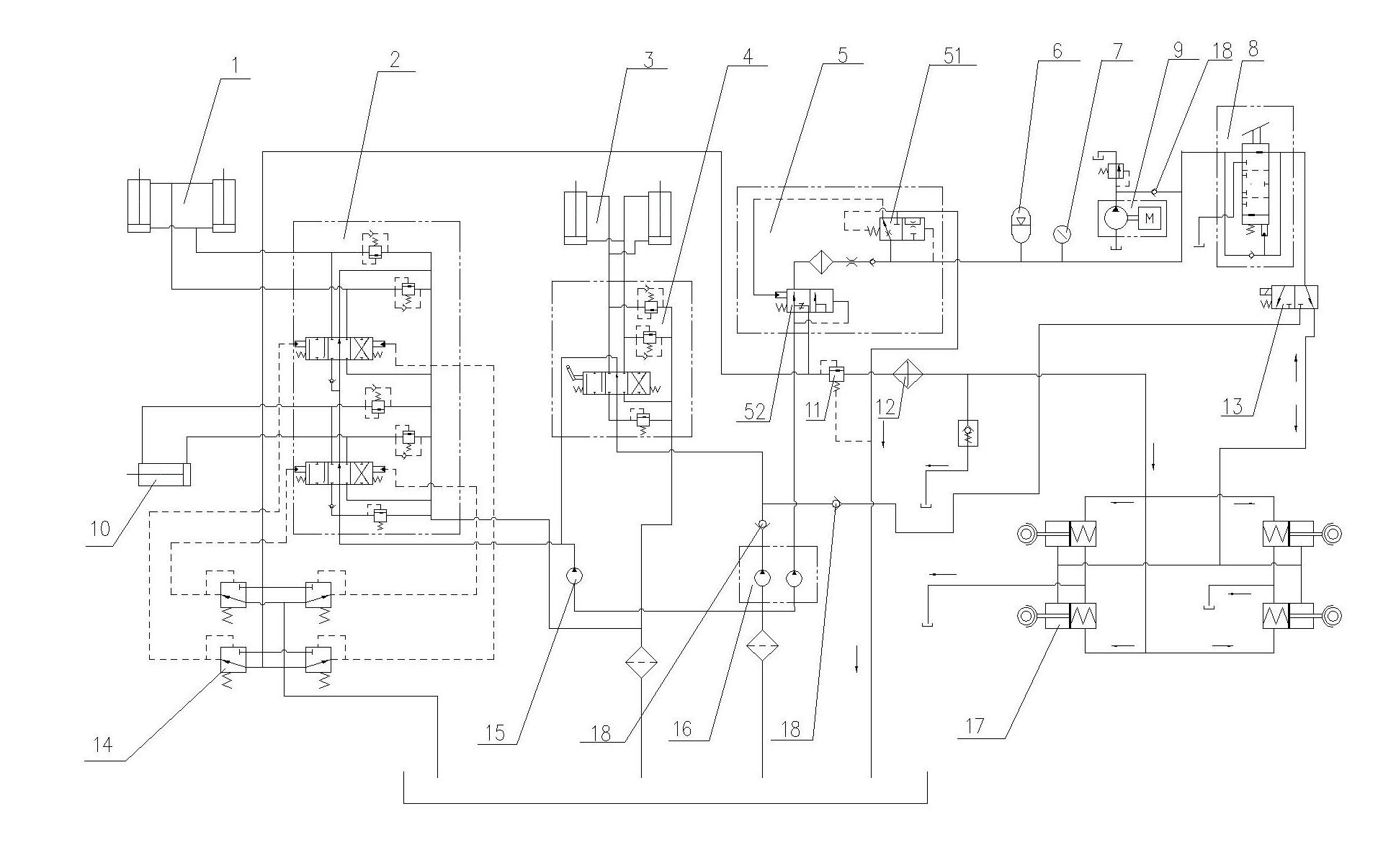

[0015] Implementation mode two, see figure 2 :

[0016] From figure 2 It can be seen that this embodiment is compared with the above-mentioned embodiment, the double gear pump 16 right pump of this embodiment is directly connected to the input end of the filling valve 5, and the backup oil supply branch is connected to the input end of the foot brake valve 8, and the electromagnetic One of the two output interfaces of the reversing valve 13 is connected to the brake 17 , and the other is connected to the input end of the steering control valve 4 through the reverse check valve 18 . ( figure 2 )

Embodiment approach 3

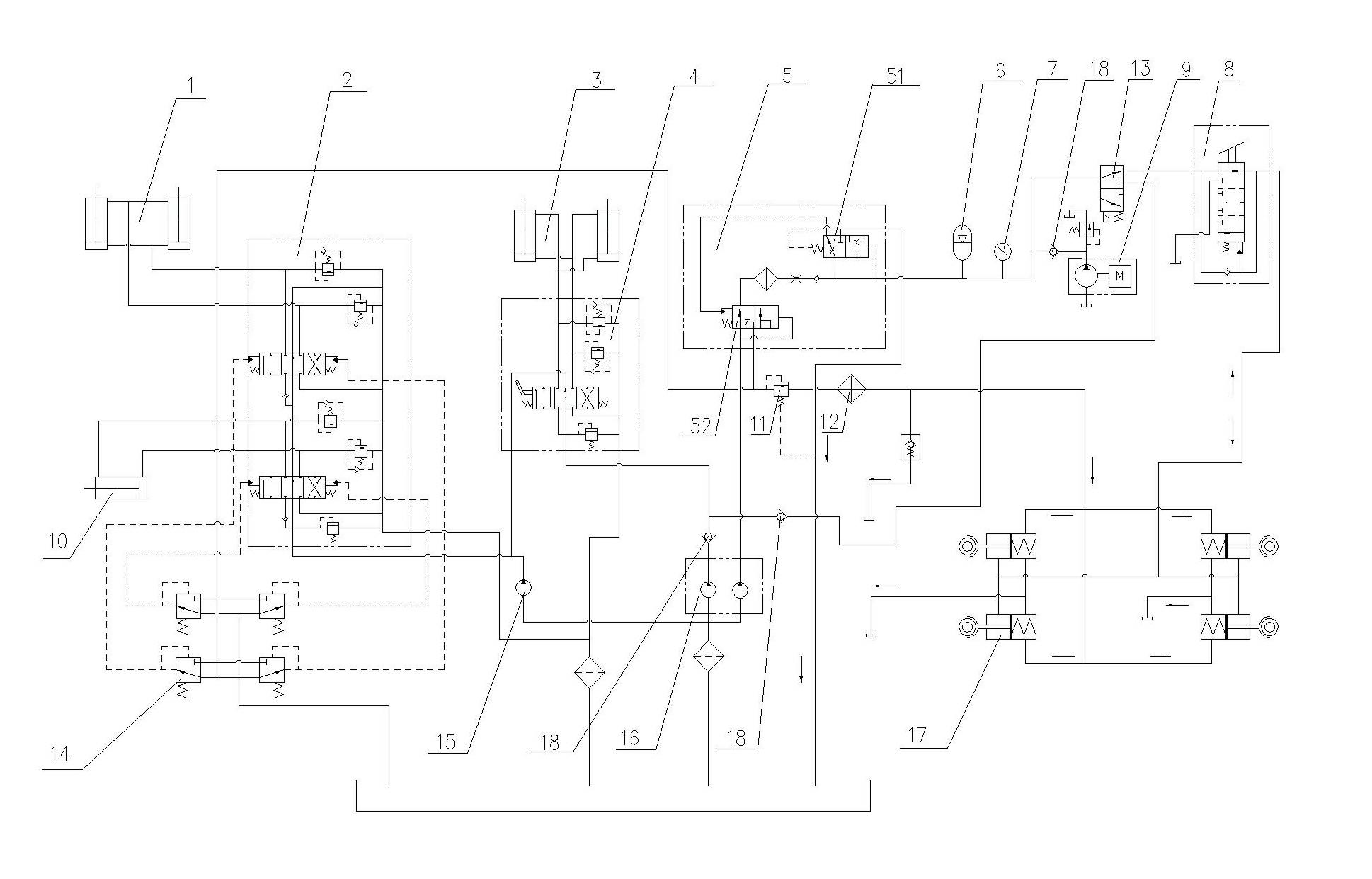

[0017] Implementation mode three, see image 3 :

[0018] Compared with Embodiment 1, the right pump of the double gear pump 16 in this embodiment is directly connected to the input end of the filling valve 5, and the backup oil supply branch and the input end of the electromagnetic reversing valve 13 are connected to the output end of the accumulator 6. One of the two output interfaces of the electromagnetic reversing valve 13 is the input end of the foot brake valve 8, and the other is connected to the input end of the steering control valve 4 through the reverse check valve 18. ( image 3 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com