Excavator boom energy-saving system based on combined energy-saving hydraulic cylinder

An energy-saving system, hydraulic cylinder technology, applied in the direction of fluid pressure actuation system components, mechanically driven excavators/dredgers, earthmoving machines/shovels, etc. It is not conducive to problems such as mass production of enterprises, and achieves the effect of meeting the requirements of excavator working conditions, reducing the cost of modification, and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

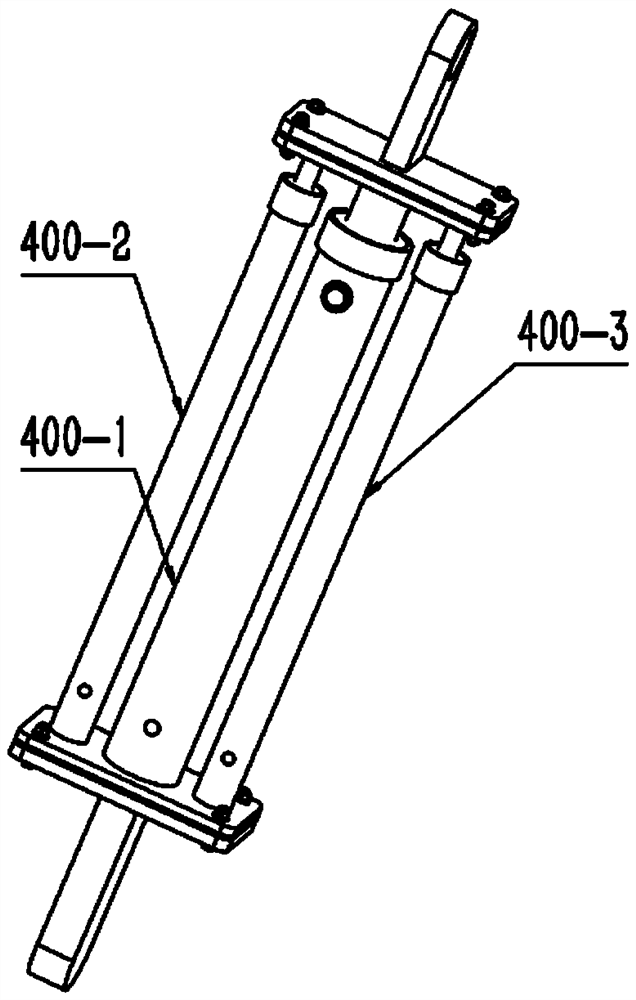

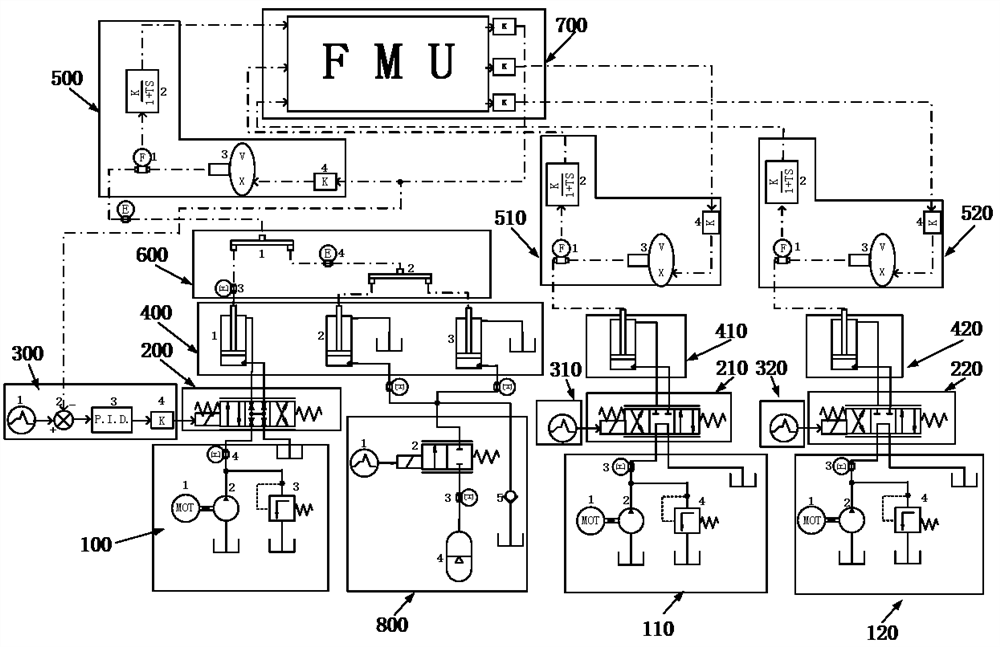

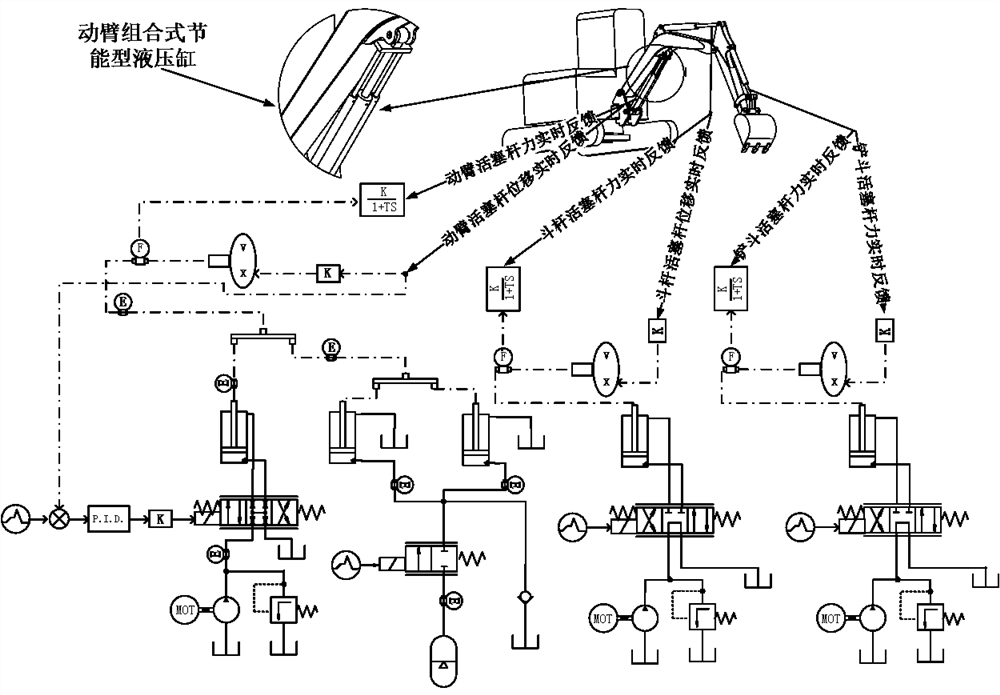

[0023] Refer to attached figure 2 An energy-saving system for an excavator arm based on a combined energy-saving hydraulic cylinder includes: the hydraulic pump output part is connected to the boom motor 100-1 and the boom hydraulic pump 100-2 to form the boom pressure energy output, and the boom is added to the output pipeline. The overflow valve 100-3 prevents the pressure of the boom hydraulic pipeline from being too high. The boom energy sensor 100-4 is located in the boom pressure energy output pipeline for measuring the total energy output of the boom; the arm motor 110-1 of the output part of the hydraulic pump It is connected with the stick hydraulic pump 110-2 to form the stick pressure energy output, and the stick relief valve 110-4 is added to the output pipeline to prevent the pressure of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com