Shock-absorbing device of shockproof joint

A technology of shock-absorbing devices and shock-proof joints, which is applied in the direction of shock-proof, building components, building insulation materials, etc., can solve the problems that buildings on both sides are easy to be damaged by collision, affect structural safety, and are not easy to repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

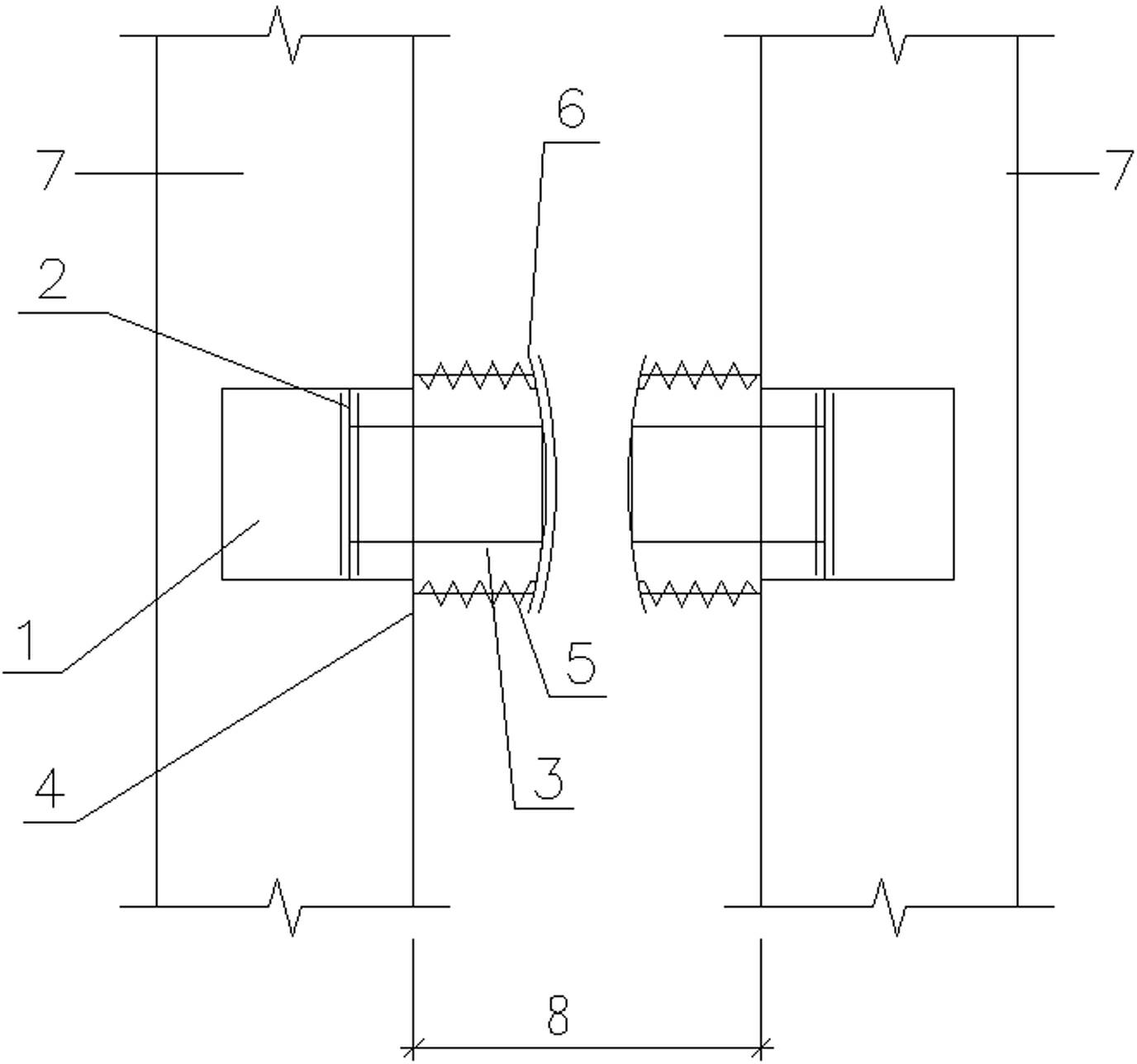

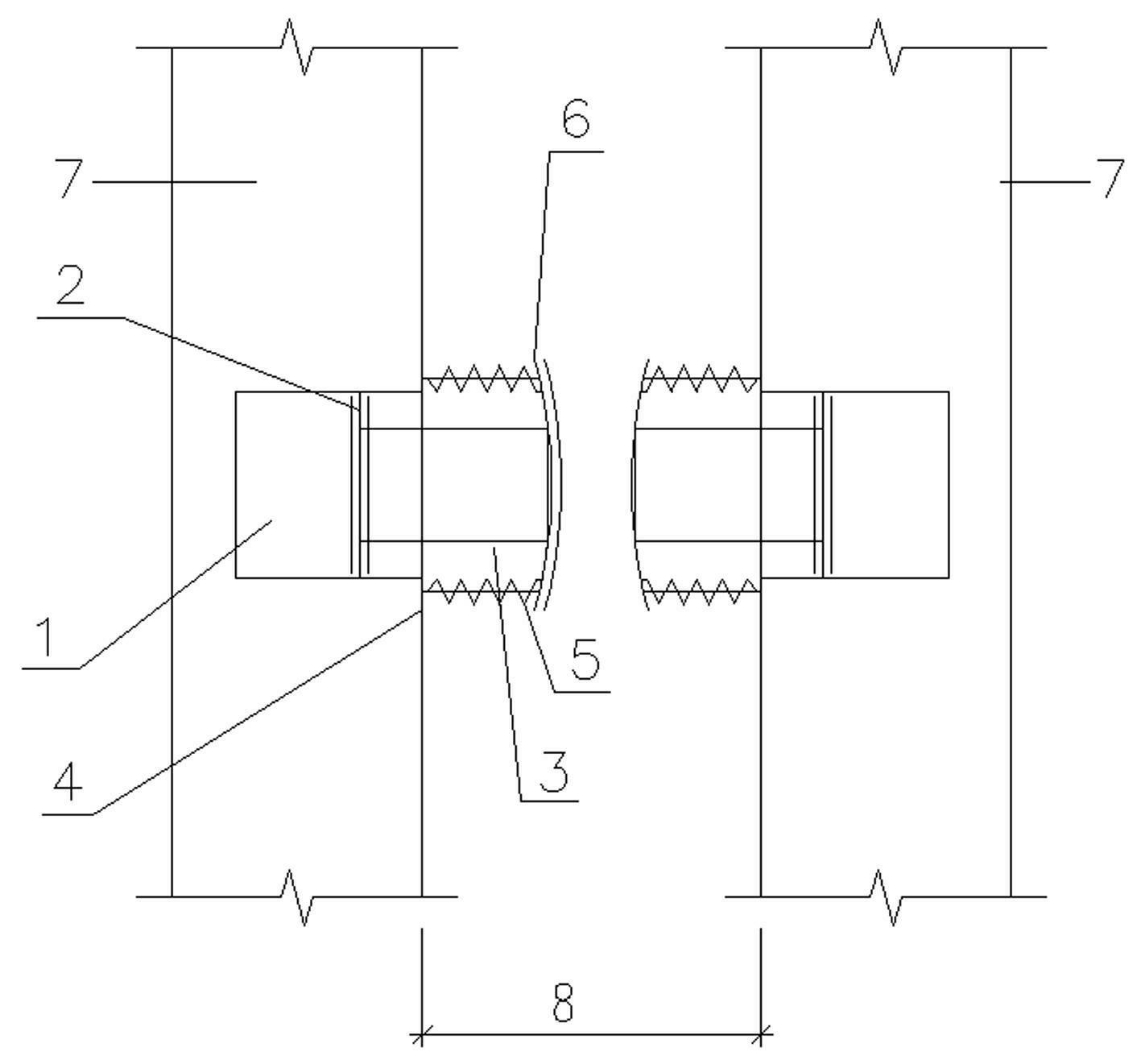

[0013] Example: such as figure 1 As shown, a shock-absorbing device for shock-proof joints includes left and right shock-absorbing units symmetrically arranged on the concrete structures 7 on both sides of the shock-proof joints 8, and the left and right shock-absorbing units include inner sides embedded in the concrete structures 7 The steel drum 1 is equipped with a piston 2 with a piston rod 3 inside the steel drum 1. The steel drum 1 is cylindrical, and the shape of the piston 2 is adapted to the steel drum 1. The piston 2 includes circular steel plates on both sides and a rubber pad in the middle. . The outer end of the piston rod 3 is provided with at least two layers of spherical steel cover plates 6. In this embodiment, the spherical steel cover plate 6 of the left shock absorbing unit is double-layered, and the spherical steel cover plate 6 of the right shock absorbing unit is single layer. The outer edge of the steel drum 1 is flush with the concrete structure 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com