Double independent driving system for shield machine

A drive system and shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problem that the center knife speed is small and cannot achieve smooth tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

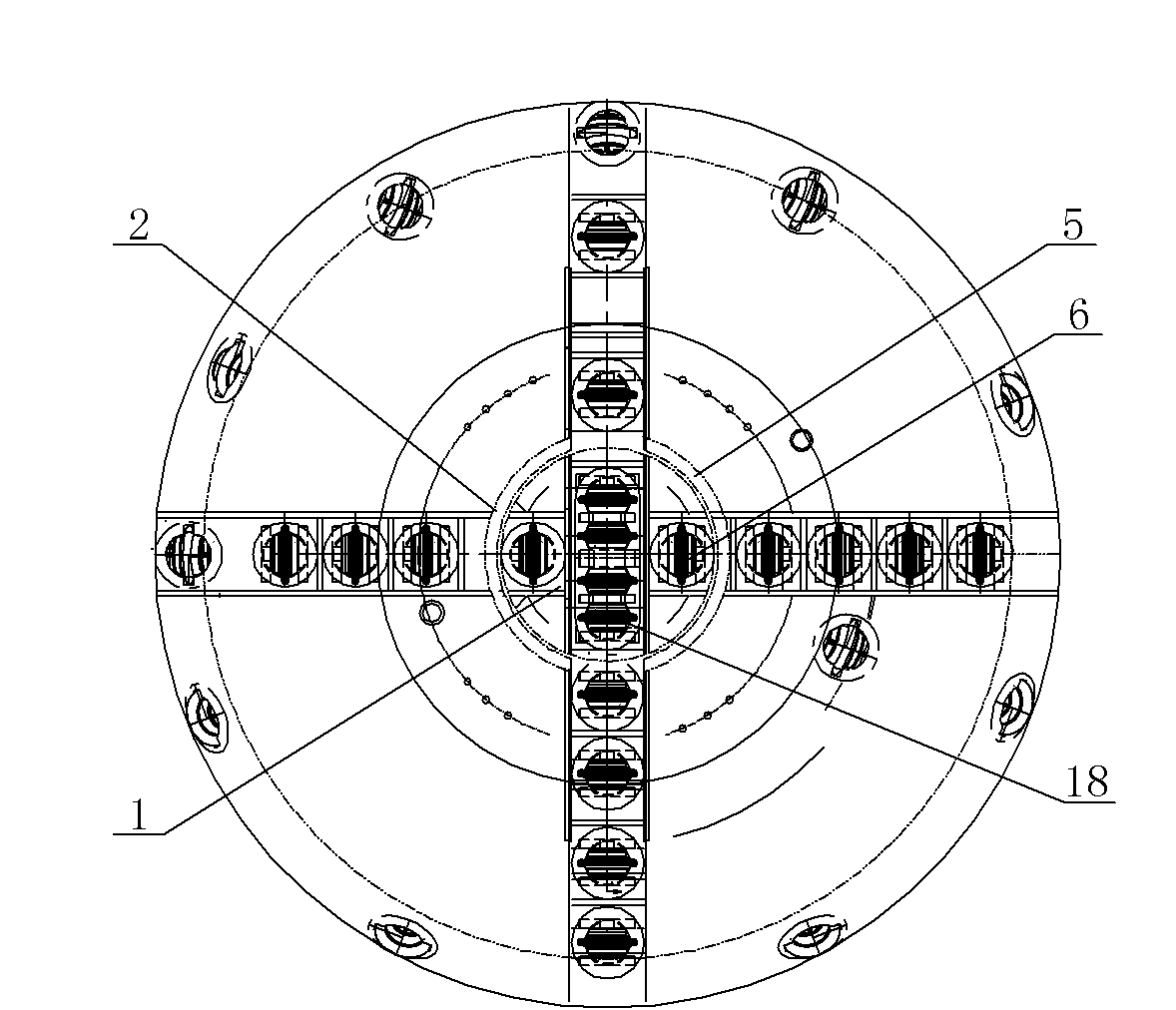

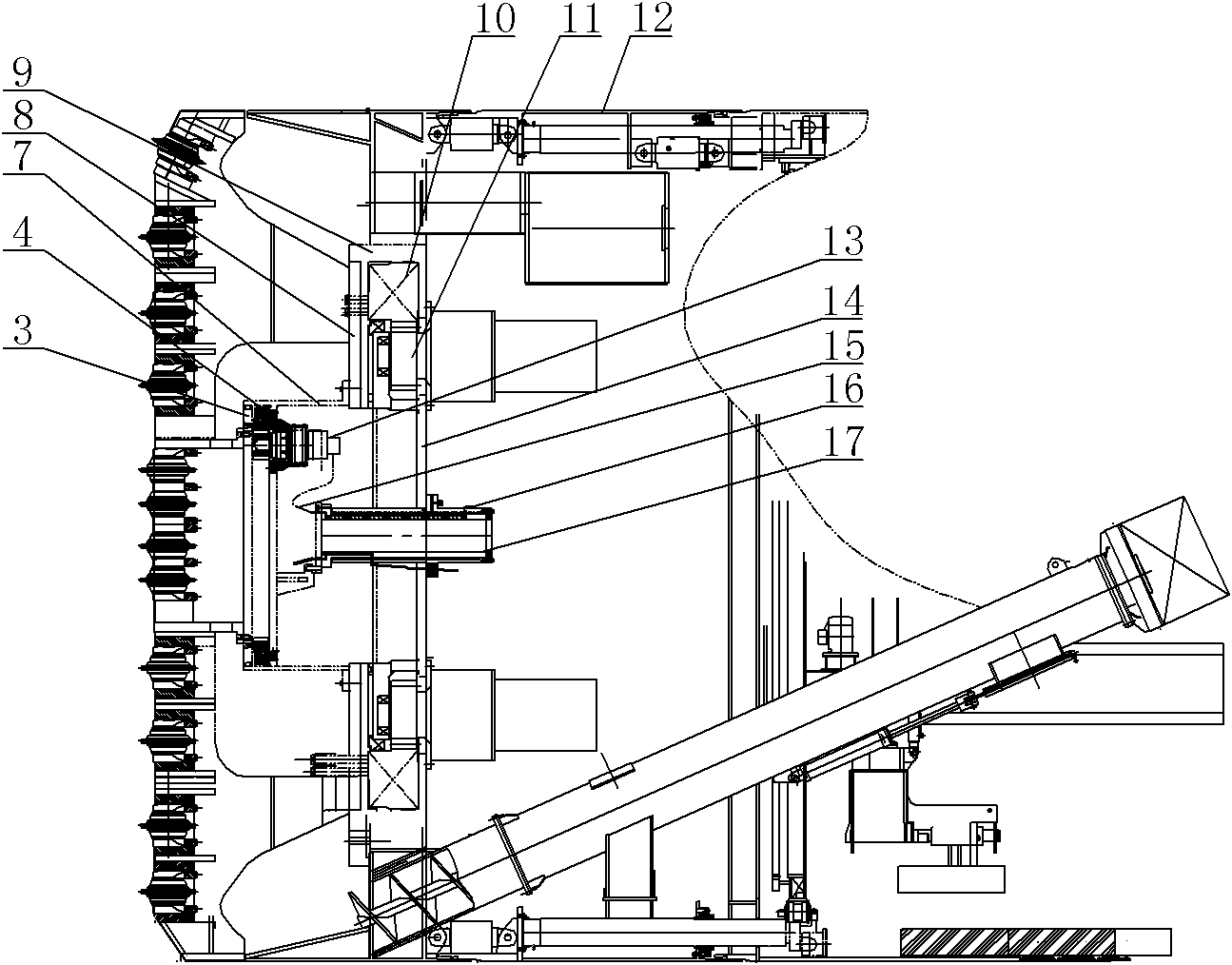

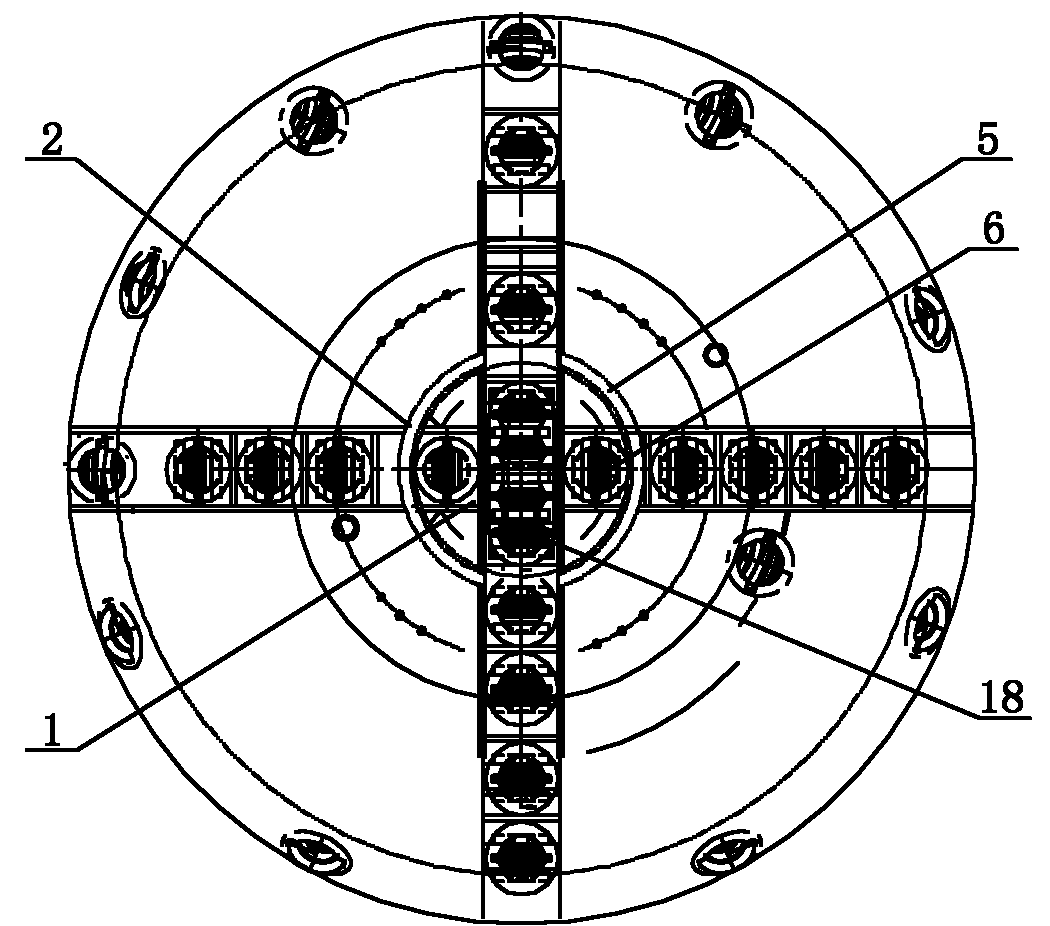

[0017] Such as Figure 1 to Figure 2 As shown, in this embodiment, a double independent driving system of a shield machine includes a front shield shell, a central cutting cutter head 1, a main cutter head, a soil bin, an outlet for cutting rock and soil, a screw conveyor, and the main cutter head of the shield machine The center of the disk is equipped with a central cutting cutter head 1, and an independent driving device for the center knife is installed on the center cutting cutter head 1. Such a setting can realize the independent rotation of the central cutting cutter head 1, and can speed up its speed relative to the main cutter head. , the steering can be consistent or inconsistent, and the most suitable speed can be selected according to the characteristics of the soil layer to ensure the smooth progress of the tunneling.

[0018] The independent driving device of the center knife is driven by the bearing and the transmission sleeve. The transmission sleeve is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com