Transmission housing for axle transmission and housing cover for transmission housing

A technology of transmission device and housing cover, applied in the field of transmission device housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

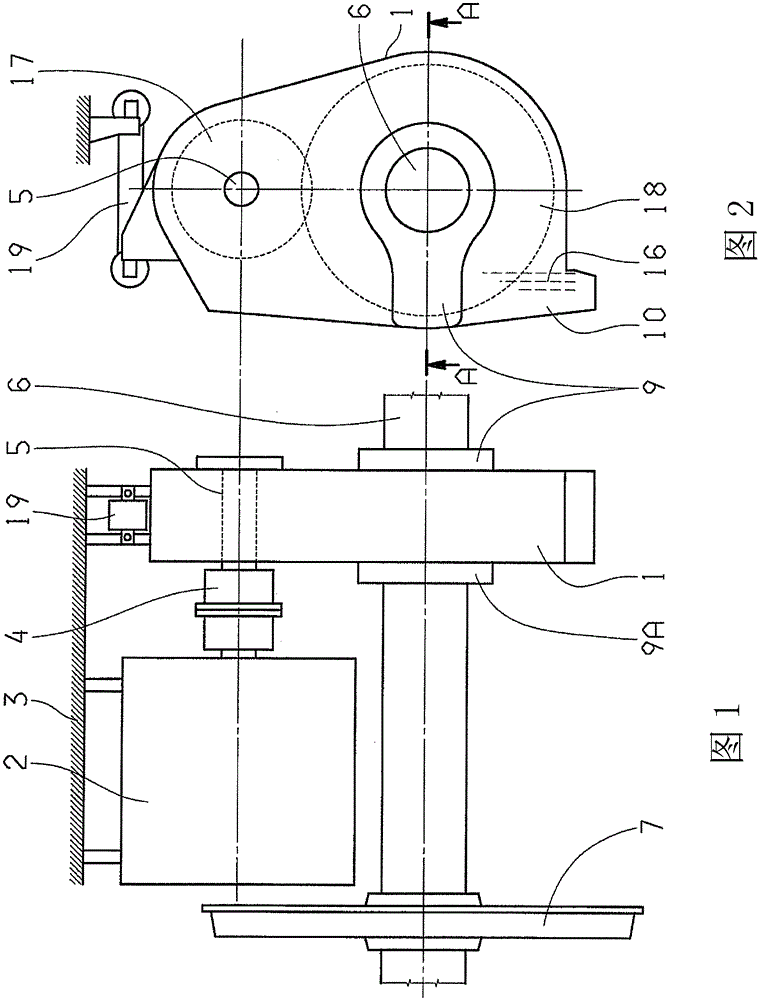

[0030] In these figures, the invention is described by way of example by means of an electric drive with a primary spur gear in the transmission housing 1 that rides on the axle.

[0031] as by figure 1 As is clear, an eg electrically driven drive motor 2 is fastened to the bogie frame 3 of the rail vehicle and is connected via a clutch 4 to a drive shaft 5 mounted in the transmission housing 1 of the axle transmission. Likewise arranged in the transmission housing 1 is a wheel shaft 6 mounted axially parallel to the drive shaft 5 , which is coupled to the drive shaft 5 via a spur gear stage. The wheel axle 6 serves to drive the wheels 7 of the rail vehicle. The transmission housing 1 is supported via a torque arm 19 on the bogie frame 3 of the rail vehicle.

[0032] as by figure 2 As obtained, the spur gear stage comprises a first smaller gear 17 and a second larger gear 18 . For lubricating the axle transmission, a lubricant or oil supply is provided in the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com