Rotors of electric motors, motors of motor vehicles, especially asynchronous motors and motor vehicles

A rotor and annular space technology, applied to the rotor of the motor, can solve the problems of complex configuration of the holder and increase of the manufacturing cost of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

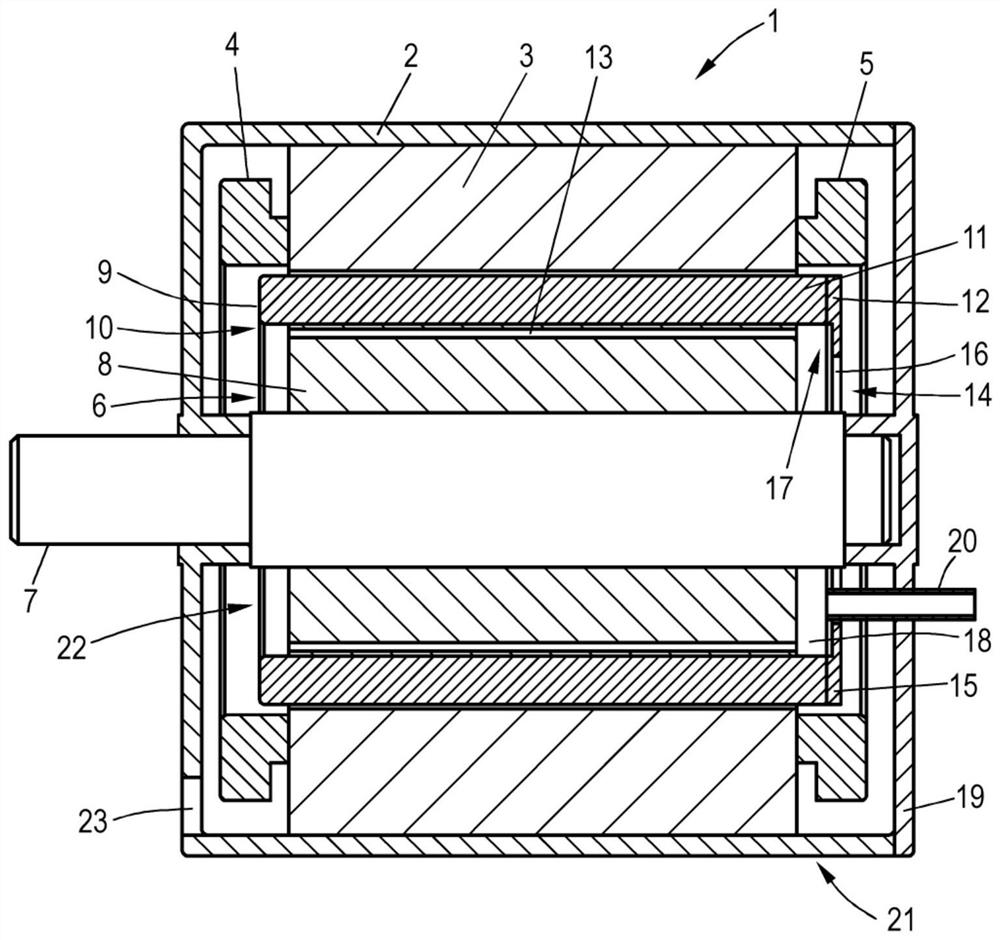

[0028] figure 1 A sectional view of an exemplary embodiment of an electric machine 1 in the form of an asynchronous machine is shown, with a housing 2 , a stator 3 and a rotor 6 coupled to a shaft 7 , the stator having a plurality of winding heads 4 , 5 .

[0029] The rotor 6 has a rotor body 10 which includes a laminated core 8 and a squirrel-cage winding 9 . The squirrel-cage winding 9 has a plurality of rotor bars 11 , which pass substantially axially through the laminated core 8 and are connected at their respective ends by short-circuit rings 12 . The laminated core 8 is also penetrated by a plurality of axial cooling channels 13 through which a cooling medium, for example oil, can flow in order to dissipate heat from the interior of the rotor 6 .

[0030]The rotor 6 also has a cover plate 15 on the end face 14 , which is fastened to the rotor body 10 . The fastening to the short-circuit ring 12 takes place here by means of fastening elements (not shown, for example scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com