Rotary kiln system capable of incinerating waste tires

A technology for waste tires and rotary kiln, applied in the field of rotary kiln, can solve the problem of late start of research and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

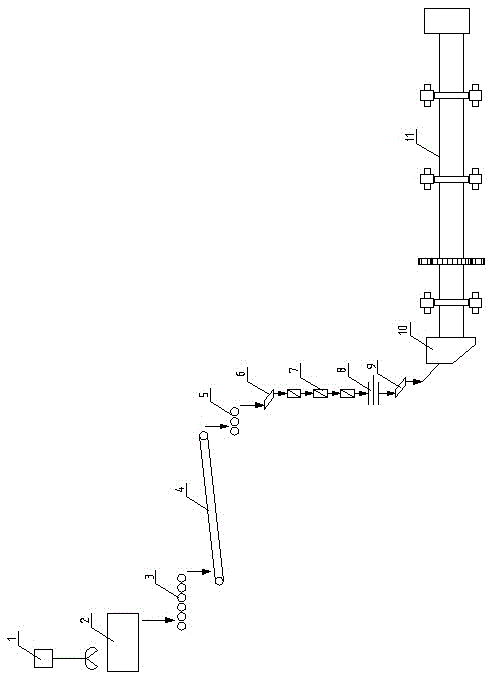

[0018] see figure 1 The rotary kiln system capable of incinerating waste tires described in this embodiment consists of a grab machine 1, a box feeder 2, a first roller conveyor 3, a belt conveyor 4, a second roller conveyor 5, and a second roller conveyor. A feeding slide 6, an electric triple air lock valve 7, a pneumatic flapper valve 8, a second feeding slide 9 and a rotary kiln 11, the box type feeder 2 is a carriage structure controlled by hydraulic drive Equipment, the first roller conveyor 3 is set under the box feeder 2, the feeding port of the box feeder 2 corresponds to the feeding end of the first roller conveyor 3, and the bottom of the first roller conveyor 3 The belt conveyor 4 is set, the delivery terminal of the first roller conveyor 3 corresponds to the feeding end of the belt conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com