Direct type backlight source module

A backlight, direct-type technology, applied in the field of direct-type backlight modules, can solve the problems of long light mixing distance, direct-type backlight module can not reach the ideal thickness, etc., to reduce the light mixing distance and realize thin design , uniform light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

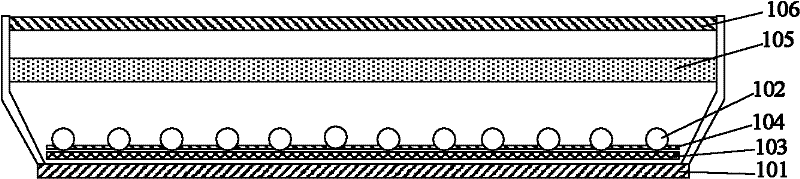

[0021] The inventors of the present invention found that: in the existing direct-type backlight module, there are problems including: the light mixing distance in the vertical direction is long, and the use of a diffuser plate structure with a certain thickness for light mixing results in direct-type backlight The problem that the module cannot reach the ideal thickness.

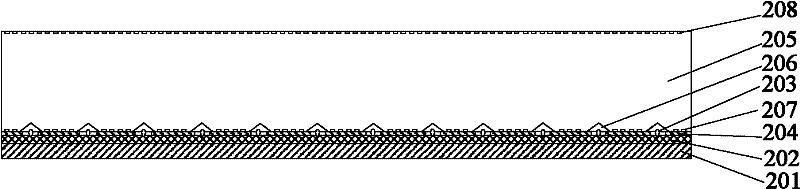

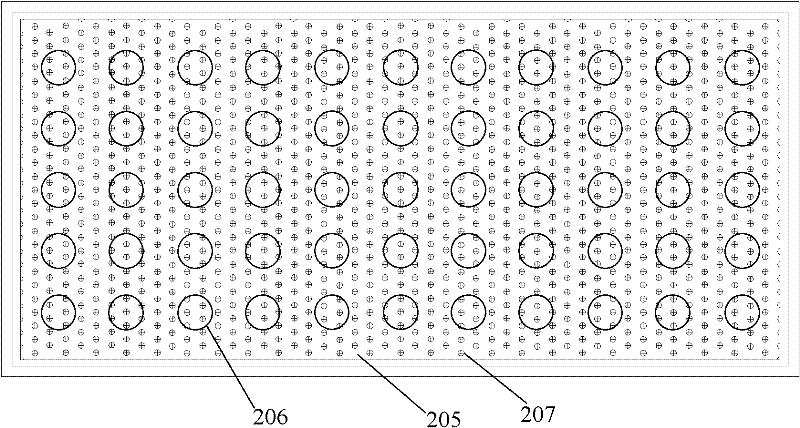

[0022] Therefore, the inventor of the present invention proposes a direct-lit backlight module, which improves the diffuser plate adjacent to the LED array, and mainly opens a light-incident bottom surface of the diffuser plate corresponding to the LED light source in the LED array. The tapered groove and the bottom surface are designed with a dot structure that is conducive to the scattering of LED incident light, which can reduce the required light mixing distance in the vertical direction while ensuring sufficient light mixing, and is conducive to the realization of direct-type backlight modules. Thin des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com