Family bar door and manufacture method thereof

A manufacturing method and technology for bar doors, which are applied to household refrigeration devices, home appliances, lighting and heating equipment, etc., can solve the problems of lack of aesthetics, increase costs, affect the aesthetics of home bar doors, etc., to reduce production costs, avoid chromatic aberration, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

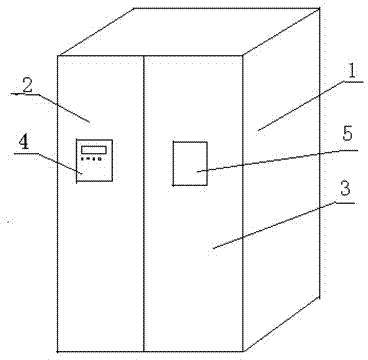

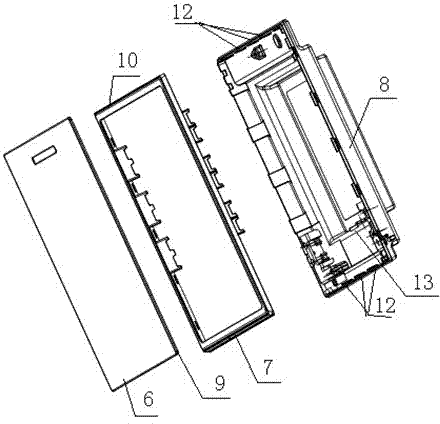

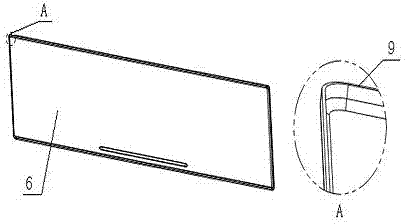

[0034] Embodiment 1 The present invention discloses a home bar door, such as figure 2 As shown, it includes a door panel 6, a connecting support frame 7 and a door cover 8. The front side of the connecting support frame 7 is connected with the door panel 6, and the back side of the connecting support frame 7 is connected with the door cover 8. On the door cover 8 There is a bubble injection port 13. The bubble injection port 13 is connected to the cavity formed by the assembly of the door panel 6, the connection support frame 7 and the door cover 8. The door panel 6 adopts the punching hole of the metal door panel of the refrigerator door. Blanking manufacturing, such as image 3 Shown, the back side of described door panel 6 has flanging 9, as Figure 4 As shown, the front side of the connecting support frame 7 has a groove 10 corresponding to the back flange 9 of the panel 6 and can be buckled, as Figure 5 As shown, the back side of the connecting support frame 7 has a b...

Embodiment 2

[0035] Embodiment 2 The present invention discloses a home bar door, such as figure 2 As shown, it includes a door panel 6, a connecting support frame 7 and a door cover 8. The front side of the connecting support frame 7 is connected with the door panel 6, and the back side of the connecting support frame 7 is connected with the door cover 8. On the door cover 8 There is a bubble injection port 13. The bubble injection port 13 is connected to the cavity formed by the assembly of the door panel 6, the connection support frame 7 and the door cover 8. The door panel 6 adopts the punching hole of the metal door panel of the refrigerator door. Blanking manufacturing, such as image 3 Shown, the back side of described door panel 6 has flanging 9, as Figure 4 As shown, the front side of the connecting support frame 7 has a groove 10 corresponding to the back flange 9 of the panel 6 and can be buckled, as Figure 5 As shown, the back side of the connecting support frame 7 has a b...

Embodiment 3

[0042] Embodiment 3 The refrigerator door is punched, and the punched and blanked metal plate is used as the manufacturing material of the door panel of the home bar door. The four sides of the metal plate are flanged, and the flanging of the door panel is continuous. Connect the connecting support frame with the door cover, snap the boss on the side of the connecting support frame into the card slot of the door cover, match the door panel obtained in step 1 with the connecting support frame, and snap the flange of the metal panel into the connection In the groove of the support frame, place the assembly obtained in step 3 in the foaming mold, and inject foaming liquid into the home bar door from the foam injection port of the door cover. The foaming liquid is hard polyurethane foam Material, through the foaming and curing of rigid polyurethane foaming liquid, the fixing of various parts of the door of the home bar is realized.

[0043] The home bar door and its manufacturing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap