Device for detecting position of broken roller of kiln

A detection device and a technology for broken rolls, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of high cost of electric eyes, burning of electric eyes, cumbersome adjustments, etc., and achieve the effect of safe use, economic benefits, and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

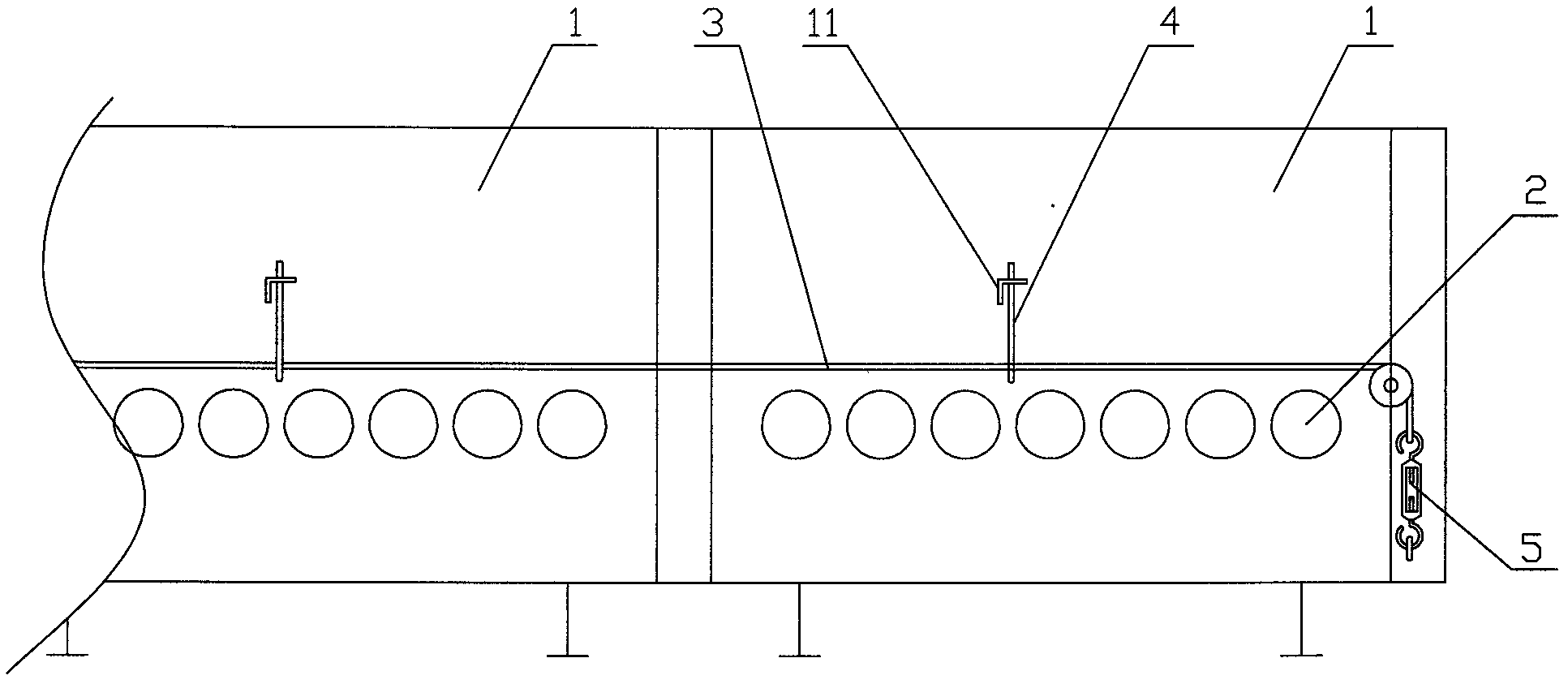

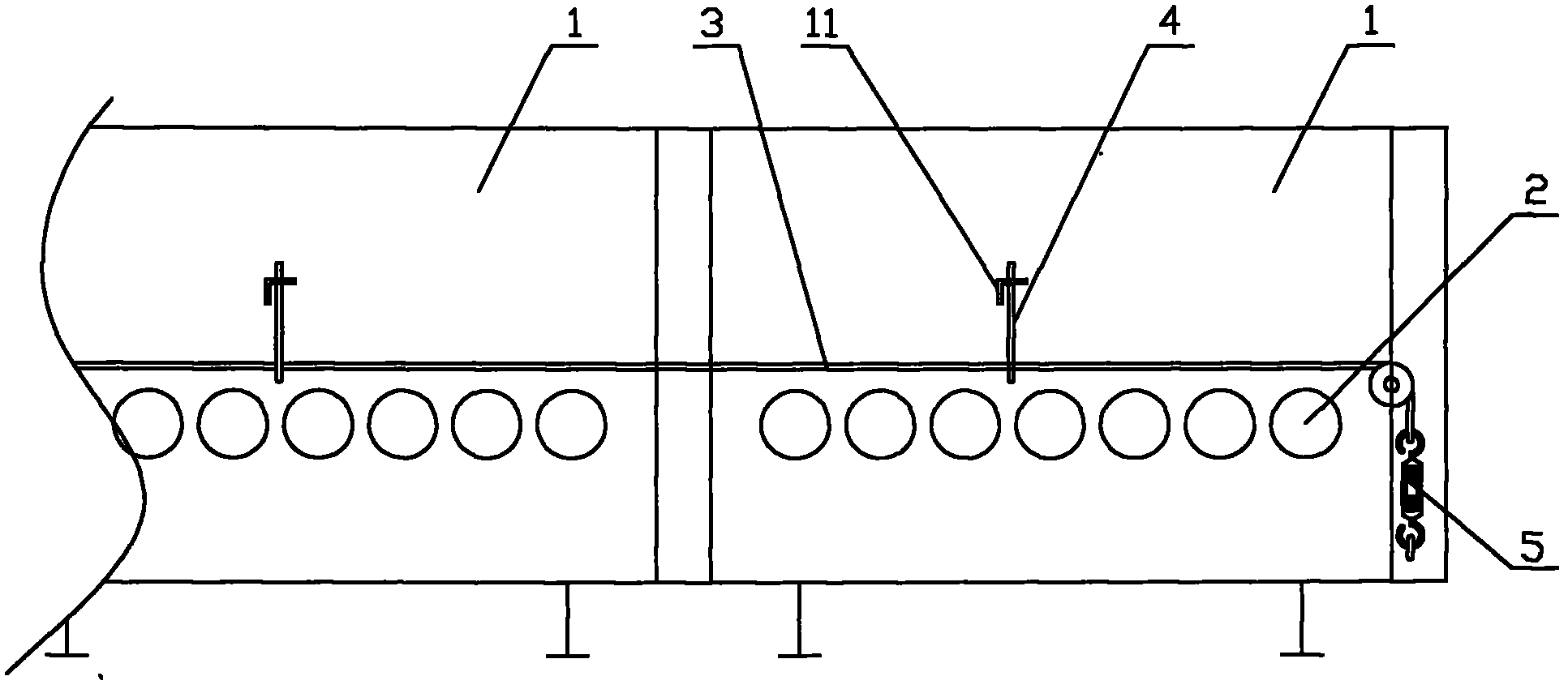

[0014] Examples, see figure 1 and figure 2 Shown: The kiln roller broken position detection device, including at least two kiln body units 1 connected together, each kiln body unit 1 is equipped with a roller bar 2, and the end of the roller bar 2 protrudes from the kiln body unit 1 outside the sidewall.

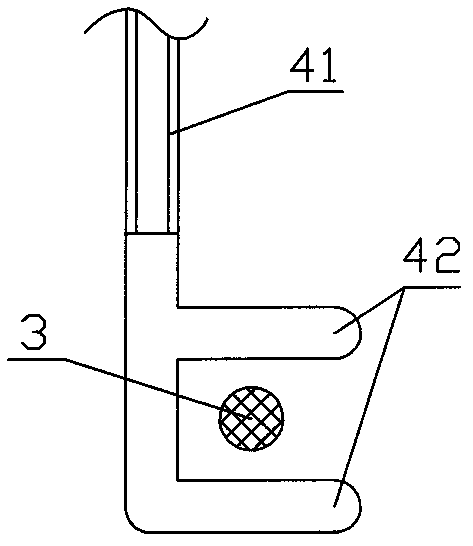

[0015] All kiln body units 1 are insulated from each other. A steel frame seat 11 is connected to the side wall of the kiln body unit 1, and a steel wire frame 4 is connected to the steel frame seat 11. The side of the wire rack 4 is provided with a metal "U"-shaped opening 42 , that is, the opening of the "U"-shaped opening 42 faces the side of the wire rack 4 . All "U"-shaped openings 42 are located on the same straight line, and the same tensioned steel wire 3 passes through all "U"-shaped openings 42 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com