Automatic sampling device and sampling method for water treatment adsorption experiment

An automatic sampling device and water treatment technology, applied in the direction of sampling device, etc., to achieve the effect of preventing cross-contamination, ensuring safe and reliable operation, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

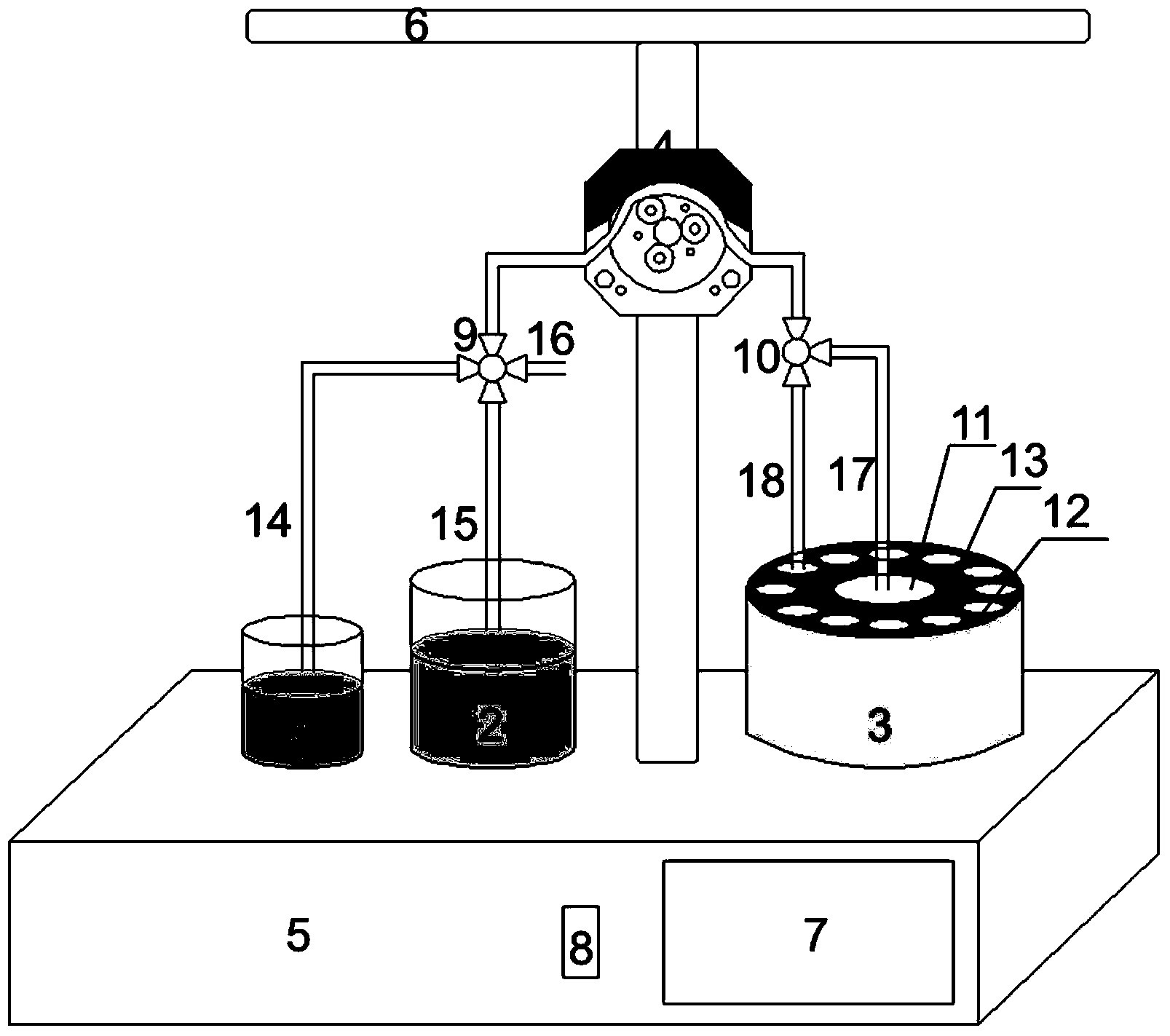

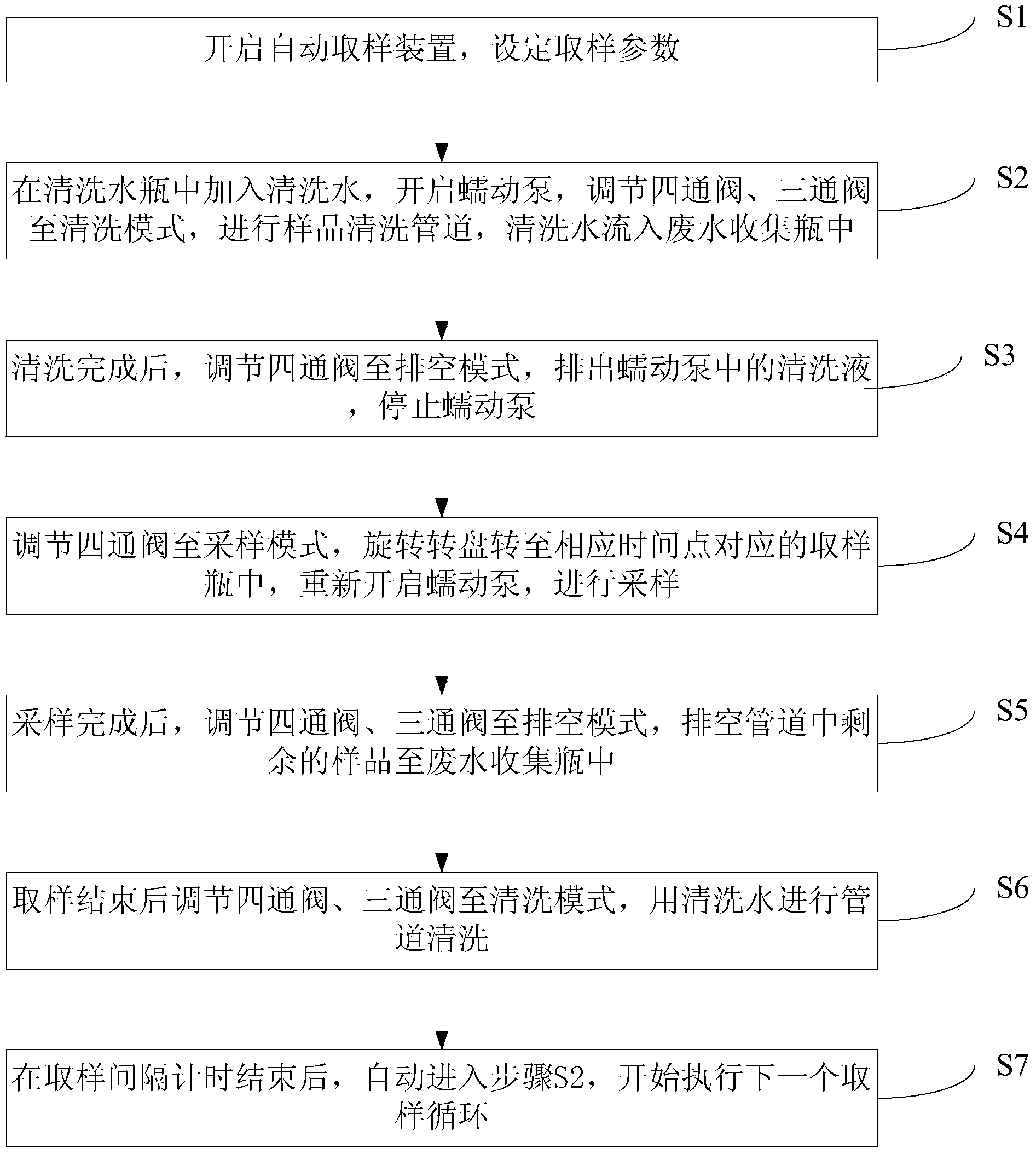

[0046] Such as figure 1 Shown, a kind of automatic sampling device that is used for water treatment adsorption experiment, comprises control system, base and the fixed bracket 6 that is arranged on the base, also includes four-way valve 9, peristaltic pump 4, three-way valve 10, and is arranged on The cleaning water bottle 1 on the base, the experimental sampling container 2 and the rotating turntable 13, the first interface of the cleaning water bottle 1 and the four-way valve 9 are connected through the cleaning pipe 14, the second interface of the four-way valve 9 and the experimental sampling container 2 are connected through a sampling tube 15, the third port of the four-way valve 9 is connected to the first port of the three-way valve 10 through the peristaltic pump 4, and the fourth port of the four-way valve 9 is connected to the Atmospheric connection, the three-way valve 10 is connected with the waste water outlet pipe 17 and the sampling outlet pipe 18 respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com